05-28/2021

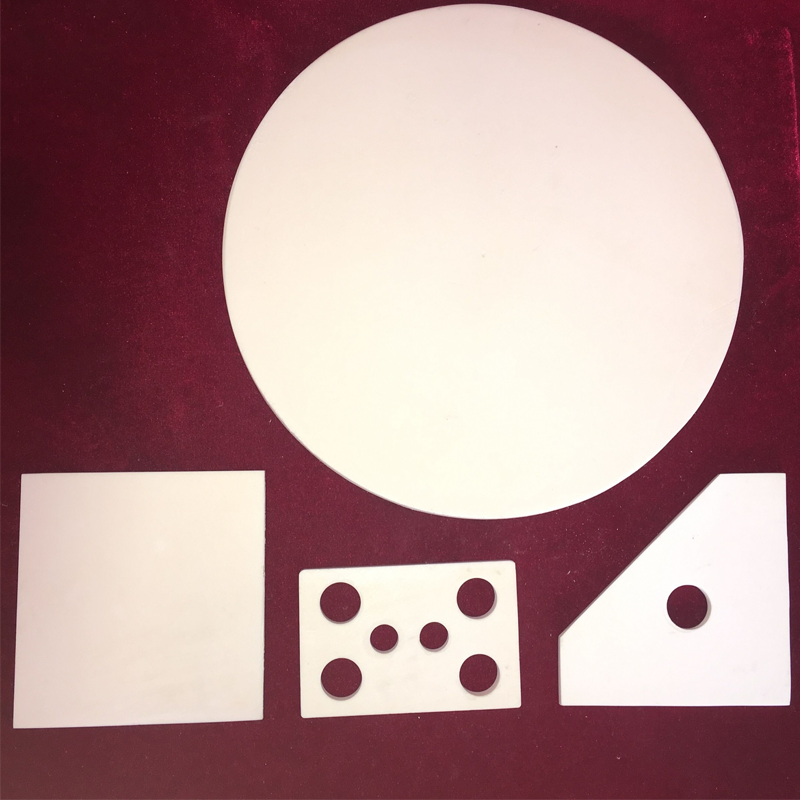

The ceramic material developed earlier is alumina ceramics. This material is resistant to high temperature and corrosion. It is an excellent and commonly used material. The material can be used to replace metal substances and extend the service life of the equipment. Increase the use of power.