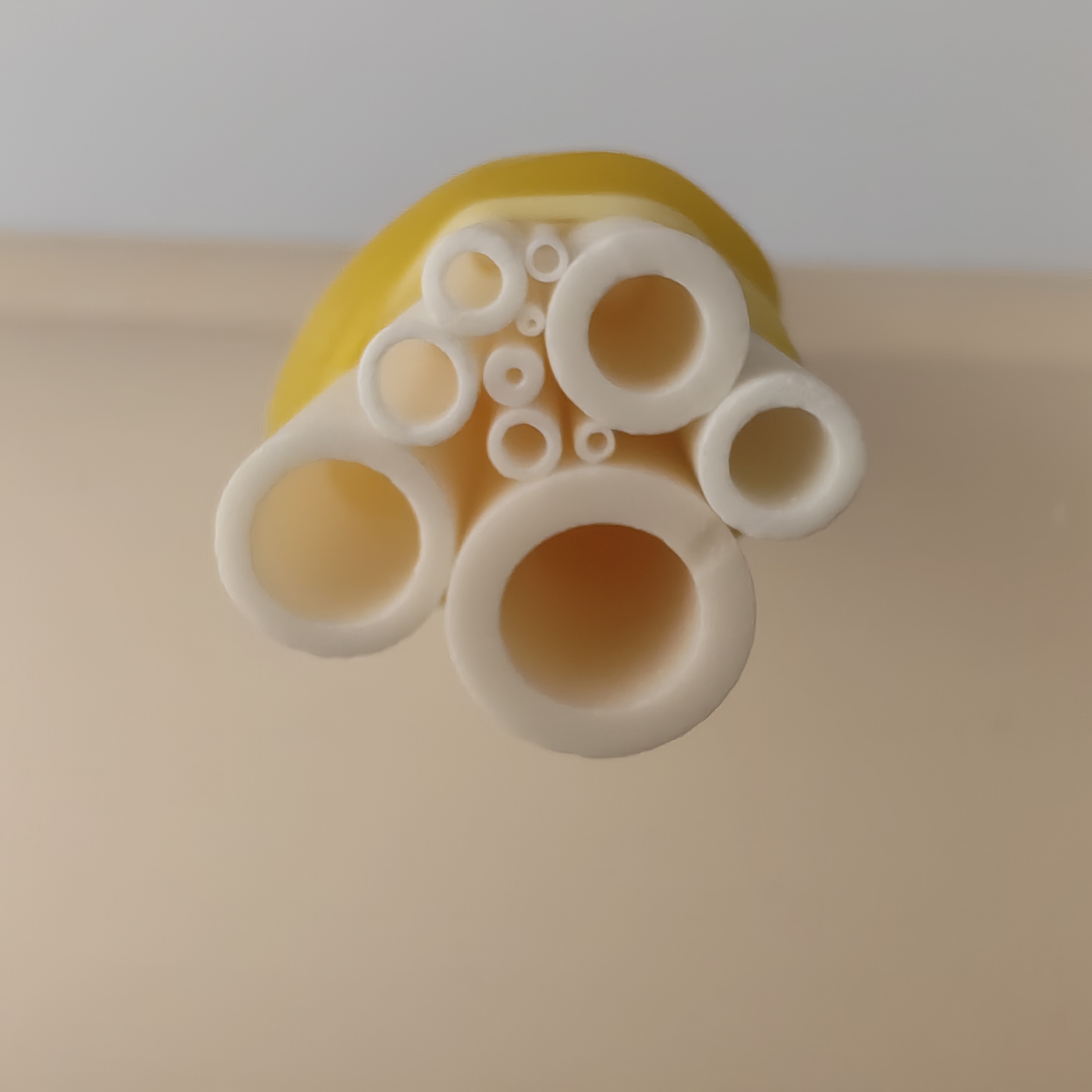

Slip casting moulding: Inject the prepared slurry into the gypsum mold and let it stand for a period of time to allow the gypsum mold to absorb moisture. The slurry forms a uniform body on the inner wall of the mold that is then dried and fired.

Isostatic pressing: During the isostatic pressing procedure, binders are blended with the ceramic powder. As a result of this process, the powder transforms into freely flowing granules that can effortlessly fill the molds.

Jinzhou Yunxing designs and manufactures its own tooling to rapidly turn around and optimise iso-pressed designs.

Iso-static pressing is more ideally suited to higher volumes than slip casting, as less drying of the parts and moulds is needed. The process can also manufacture wall thicknesses and sizes that are commercially prohibitive by slip casting.

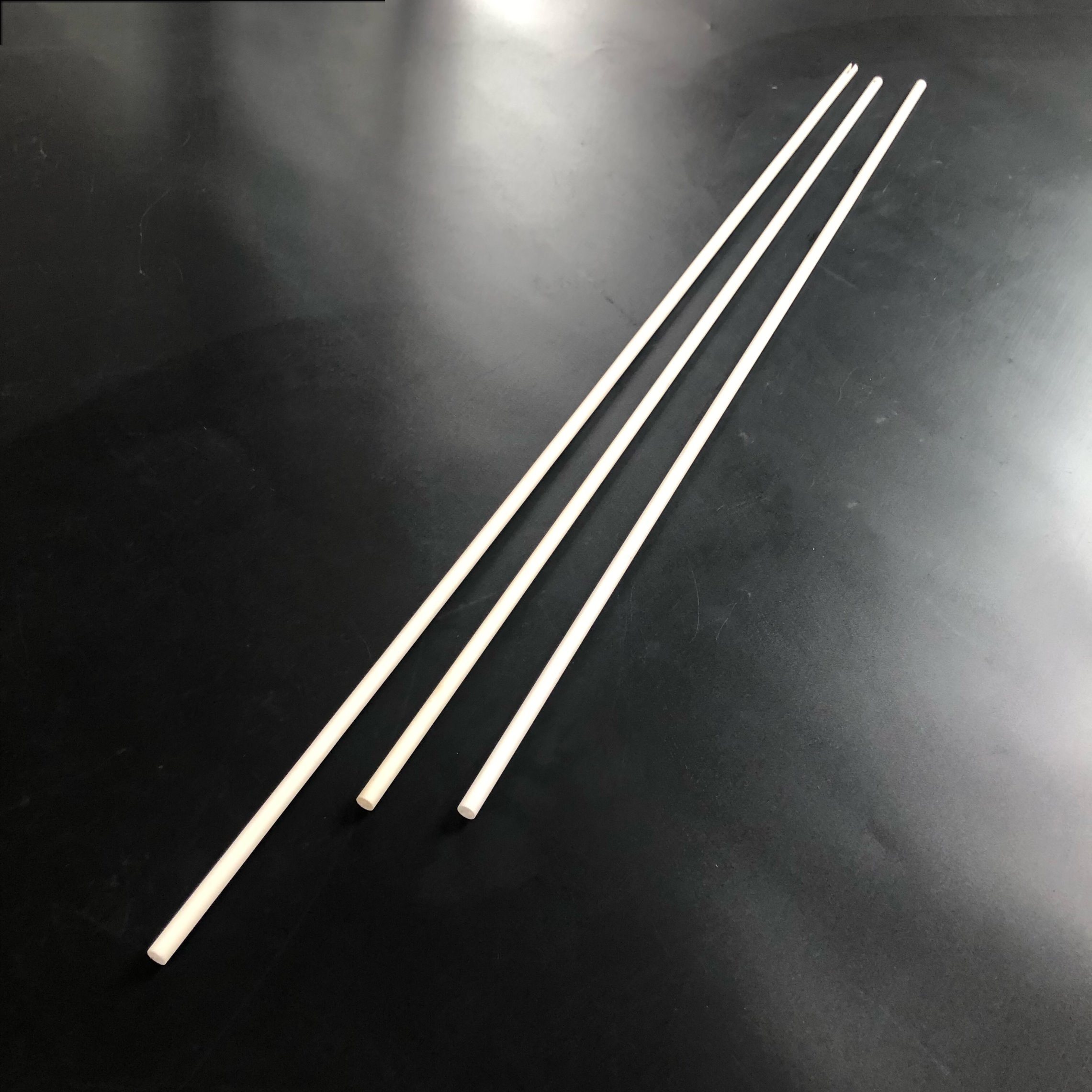

Extrusion moulding: Suitable for small diamater long tube(Outer diameter:0.8mm-12mm,Long:≤1850), the powder is extruded into shape through an extruder.