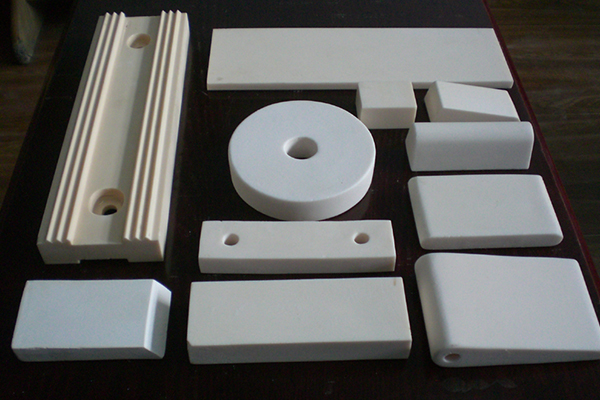

We specialize in producing 99.3% alumina ceramic products.

High temperature resistance: Long term use at 1600 ℃, short-term use at 1800 ℃.

Corrosion resistance: It has strong corrosion resistance to acidic and weakly alkaline substances, and is not suitable for strongly alkaline substances (such as sodium hydroxide, sodium peroxide) or acidic fluxes (such as potassium pyrosulfate).

Thermal shock resistance: High thermal conductivity and low coefficient of thermal expansion, able to withstand temperature fluctuations during rapid heating and cooling processes, and not easily explode due to rapid cooling and heating. (Test: No cracking after 4 times at 1550 ℃) It is recommended to increase the heating rate by 5 ℃/min to 10 ℃/min, and the cooling rate can be matched with the heating rate.

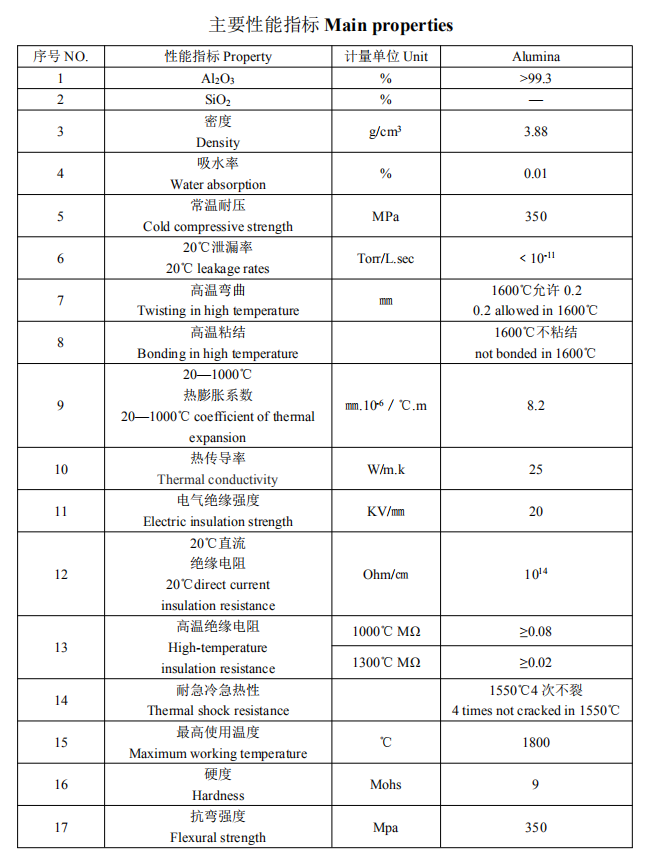

Other performance indicators are shown in the table:

We operate 4 high-temperature kilns (l,800'c) and 2 low-temperature kilns (l,400"c).

At Jinzhou Yunxing Industrial Ceramic Company, we specialize in precision high-temperature sintering of 99.3% alumina ceramics using our industry-leading 1800 High-Temperature Kiln. Engineered for ultra-dense ceramic production, our kiln operates at 1600-1800°C with multi-zone dynamic temperature control. we produce components for high-voltage insulators, industrial wear nozzles, and semiconductor wafer chucks with ±5°C uniformity and <0.1% open porosity. Controllers enable 30% faster sintering cycles while reducing warpage by 50% versus conventional tunnel kilns.

ith 25+ years of expertise in advanced ceramic thermal systems, we deliver mission-critical solutions for energy, defense, and electronics industries.

At Jinzhou Yunxing Industrial Ceramic Company, we specialize in the precision low-temperature sintering of 99.3% alumina ceramics using our advanced Low-Temperature Kiln. Designed for ultra-pure ceramic manufacturing, this kiln ensures exceptional material stability through energy-efficient operation at 300–1400°C. It achieves a density of 99.3% while minimizing thermal stress. Equipped with multi-zone temperature control and vacuum atmosphere technology, our solutions integrate German-engineered thermal regulation with Japanese precision sensors, reducing warpage by 70% compared to conventional kilns.

Surface grinder and Laser printer

Due to the nature of sintered alumina which likes to warp and bend during the sintering process, Jinzhou Yunxing Industrial Ceramics Factory has introduced a CNC surface grinder. Which with the addition of a resin bonded diamond wheel and a magnetic mounting system produces flat ground products to an exact size and flatness in an efficient way.

We do offer many ceramic substrates with different standard thicknesses, but sometimes non-standard thicknesses are required, which is when a surface grinder is really needed. The surface grinder is also useful for ensuring “custom made” products are surface ground flat and to the customers required dimensions.

Isostatic Pressing

Isostatic pressing is a dry powder forming process. As the name suggests, this process presses powders into the desired shape by applying uniform pressure in all directions. Compared with other pressing technologies, its significant advantage lies in the ability to form large parts, workpieces with high aspect ratios, and thick-walled structures. The uniform pressure distribution ensures consistent and controllable shrinkage patterns, effectively reducing the risk of deformation and cracking.

Hot die casting molding

Hot die casting molding is a widely used production process for manufacturing alumina ceramics. Its basic principle is to utilize the characteristics of paraffin wax melting when heated and solidifying when cooled. Non-plastic lean ceramic powder is uniformly mixed with hot paraffin liquid to form a flowable slurry, which is injected into a metal mold under certain pressure for molding. After cooling and solidification of the wax slurry, the molded green body is demolded and removed. The green body is appropriately trimmed, buried in an adsorbent, and heated for dewaxing. Finally, the dewaxed green body is sintered into the final product.

Products formed by this method have relatively accurate dimensions, high surface finish, and compact structures, providing more suitable solutions for your electronic components and industrial devices.

Laser etching

We can laser etch crucibles, flat plates, tubes, and rods . We can laser etch sequential numbers,trademark, barcodes, and even QR codes onto or into ceramics. Deeper imprints will remain visible even after they have been used at high temperatures, i.e. they don’t burn off.