1. Excellent high temperature resistance.

2. Strong corrosion resistance and does not react with experimental substances.

3. Excellent mechanical performance.

4. Good heat shock resistance and safe and reliable material.

5. Accept customized sizes.

6. Large stock and fast delivery.

Send Email

More

Menu

- Home

- Products

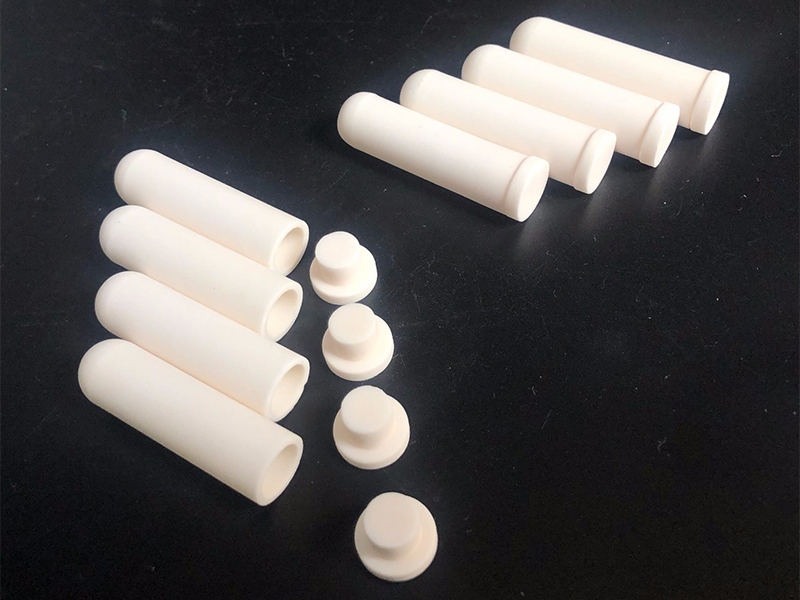

- Alumina Ceramic Tube

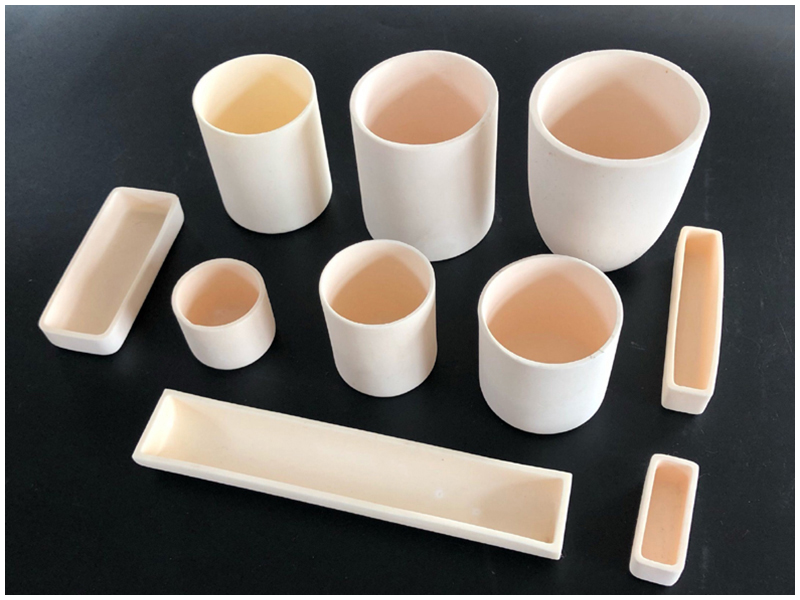

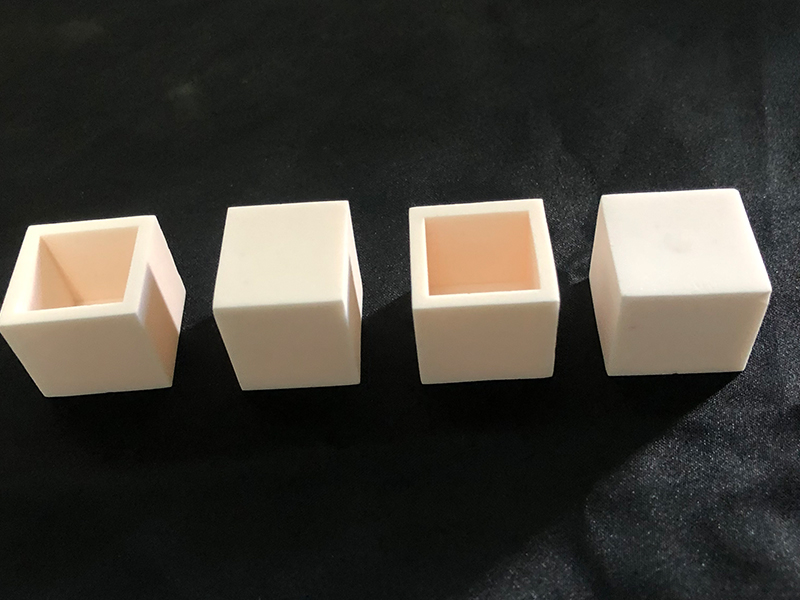

- Alumina Ceramic Crucible

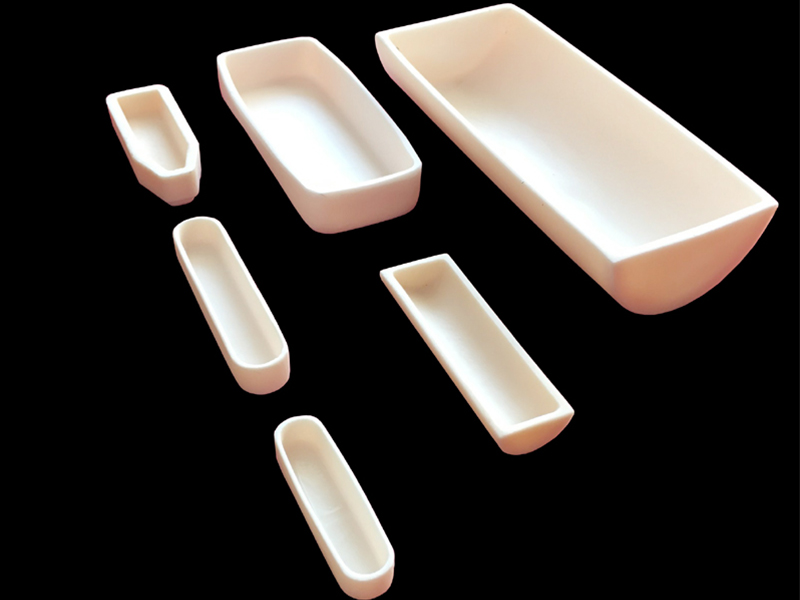

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Product News

- INDUSTRY

- Factory Show

- Factory Scale

- Process Flow

- Customized Process

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search