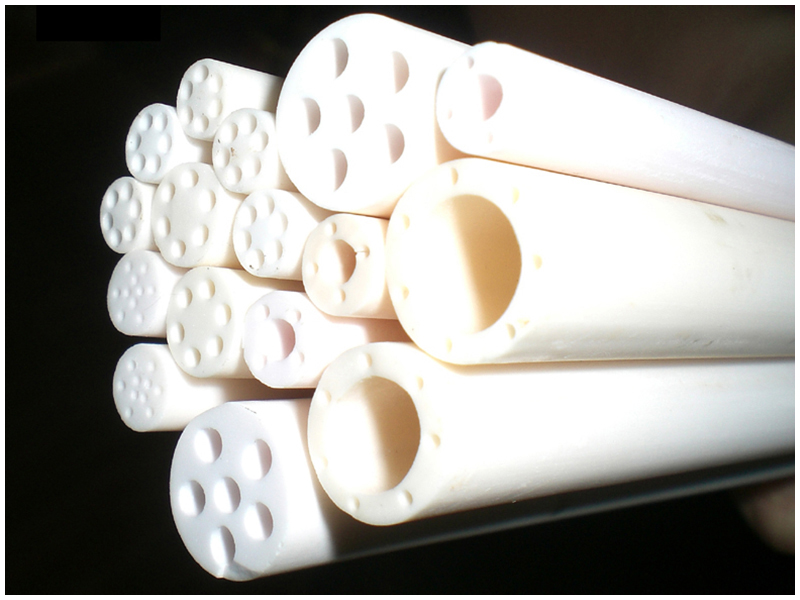

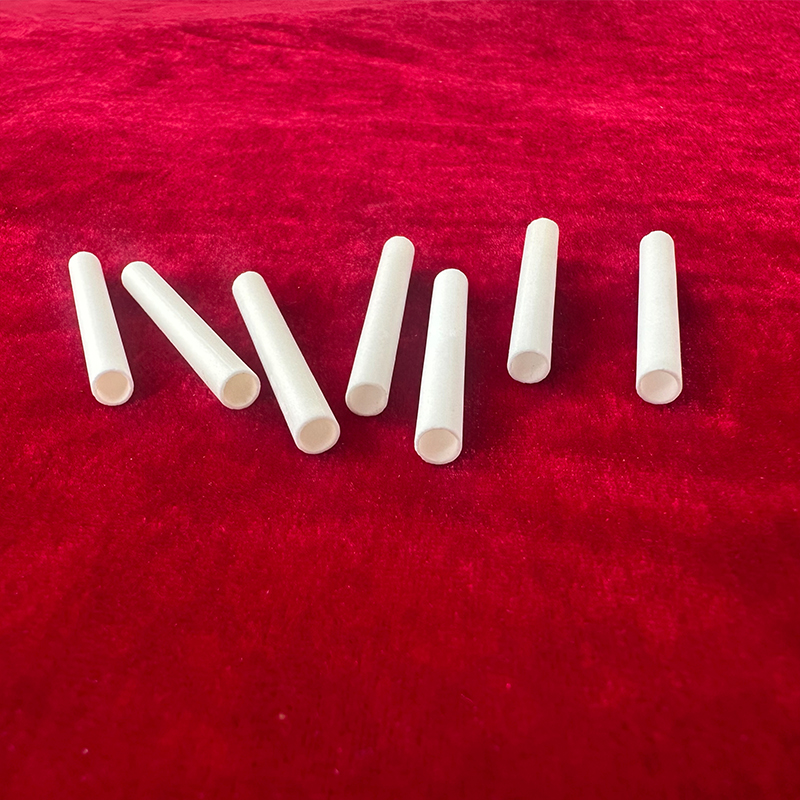

▪ Made by 99.3%-99.7% high purity alumina.

▪ Max working temperature is 1800℃.

▪ The quality can pass the SGS and DIN43724/DIN43725/DIN40680.

▪ Both end open with good verticality.

▪ Can produce the 2-10 holes, max length 1850 mm.

Send EmailMoreMenu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Product News

- INDUSTRY

- Factory Show

- Factory Scale

- Process Flow

- Customized Process

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

- VIDEO

Search