09-18/2024

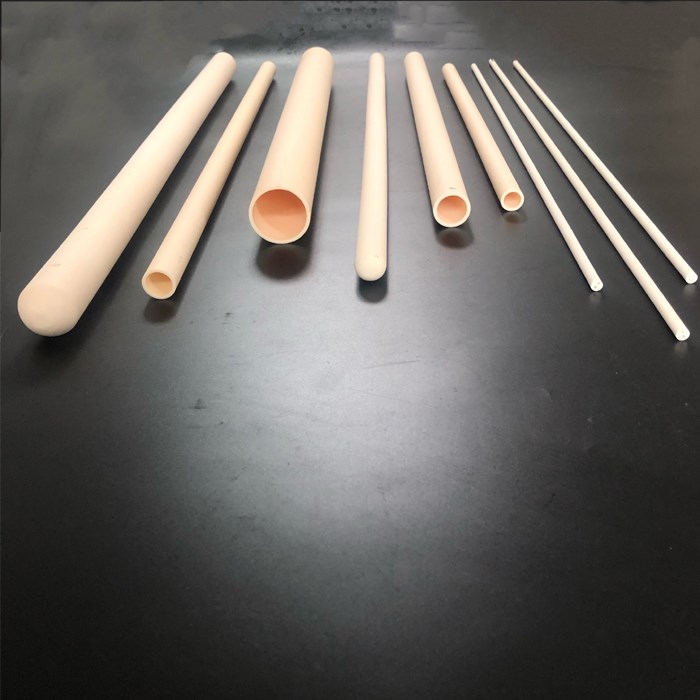

Alumina ceramics have long been known for their remarkable properties, such as high hardness, excellent thermal stability, and resistance to wear and corrosion. Among the various alumina ceramic products, the Industrial Alumina Ceramic 2-Hole Tube stands out as a critical component in many industrial applications. These tubes are widely used in high-temperature environments, particularly for housing thermocouples and other electrical instrumentation. Their unique properties make them ideal for demanding tasks in industries such as metallurgy, aerospace, and energy production.