08-17/2021

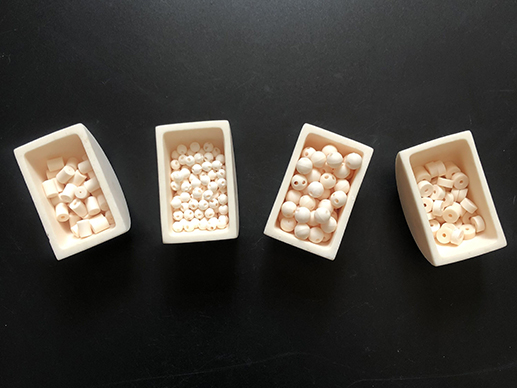

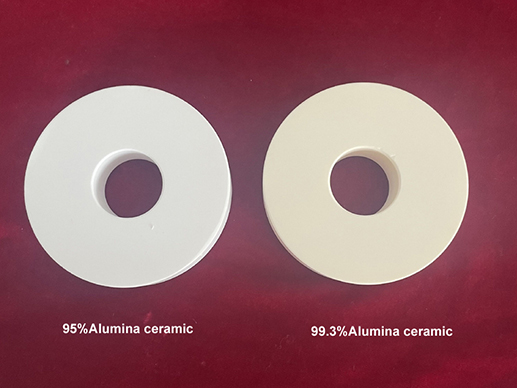

Alumina hollow spheres and their products are a new type of high-temperature thermal insulation refractory material. It has high strength, good chemical stability, light bulk density, and a large number of closed pores. It is widely used in petroleum, chemical, ceramics, and high-temperature and ultra-high temperature for national defense scientific research. On thermal equipment.