03-18/2020

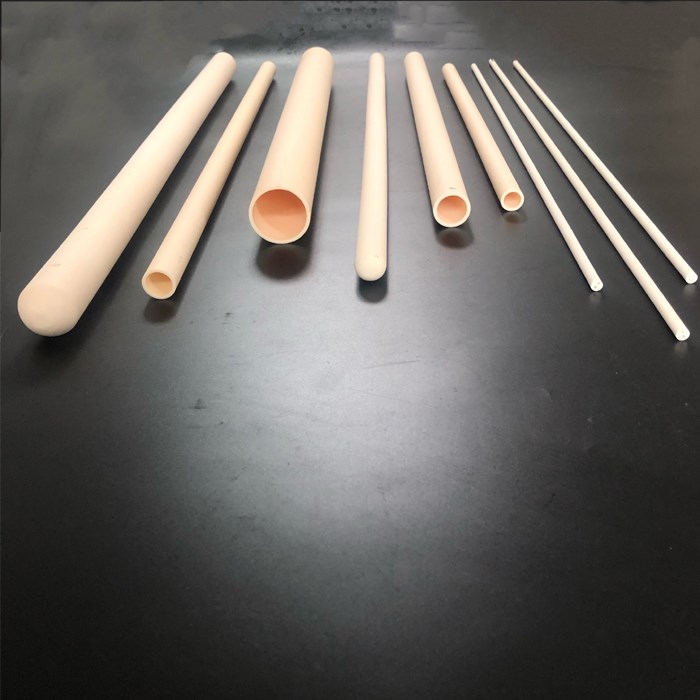

In order to prolong the service life of high purity alumina furnace tubes and reduce the losses caused by damages due to improper use, the following suggestions are hereby put forward for users' reference