Aluminum Oxide Ceramic Crucible

- YUNXING

- China Jinzhou

- 5-30 Days

- 3,000-5,000/month(Looking for distributors)

A. Crucible, as an important part of chemical equipment, is a reaction vessel for melting and refining liquid metal and heating solid and liquid.

B. It is a refractory material with high fire resistance. It can withstand a high temperature of 1800 degrees Celsius.

C. Has excellent chemical resistance and high temperature resistance.

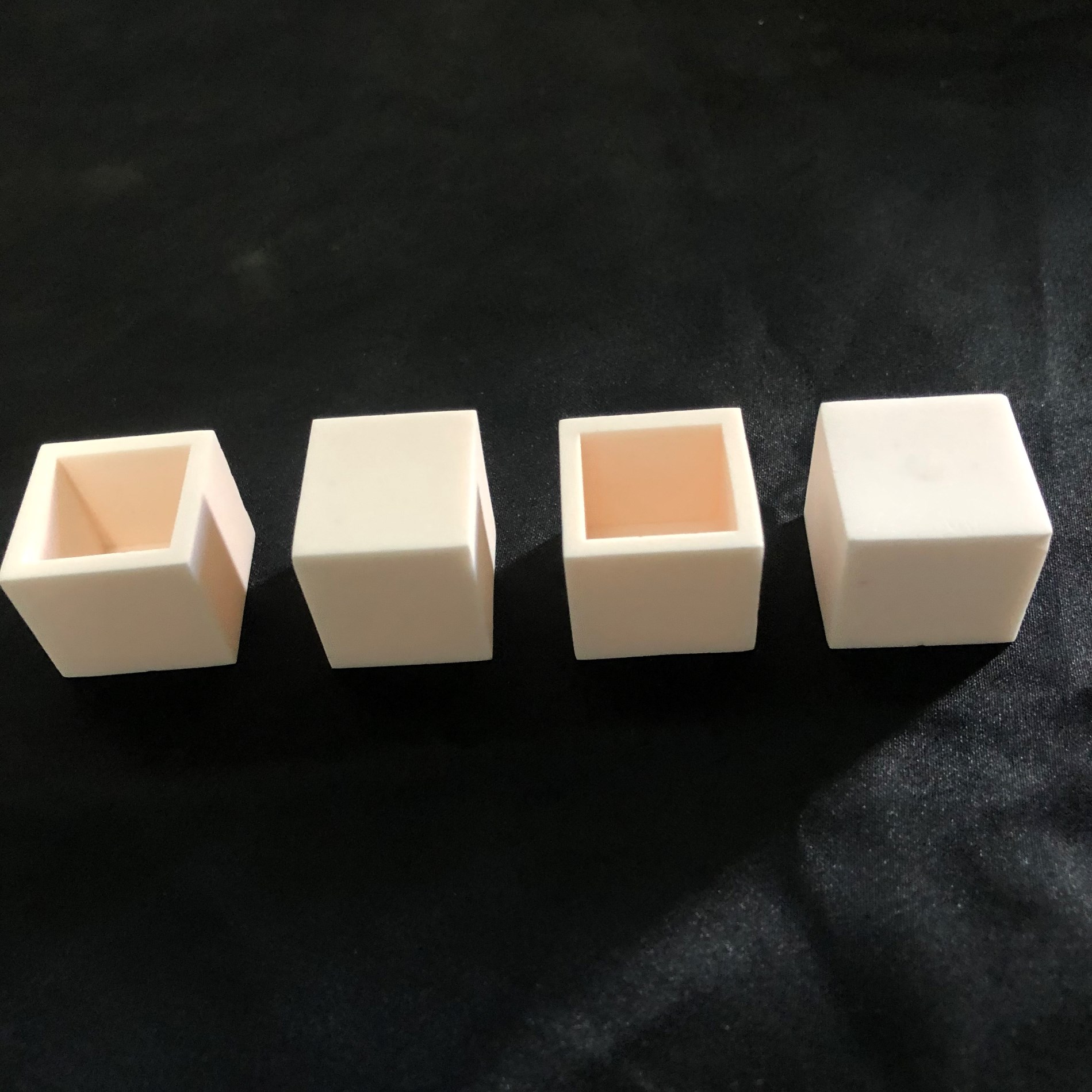

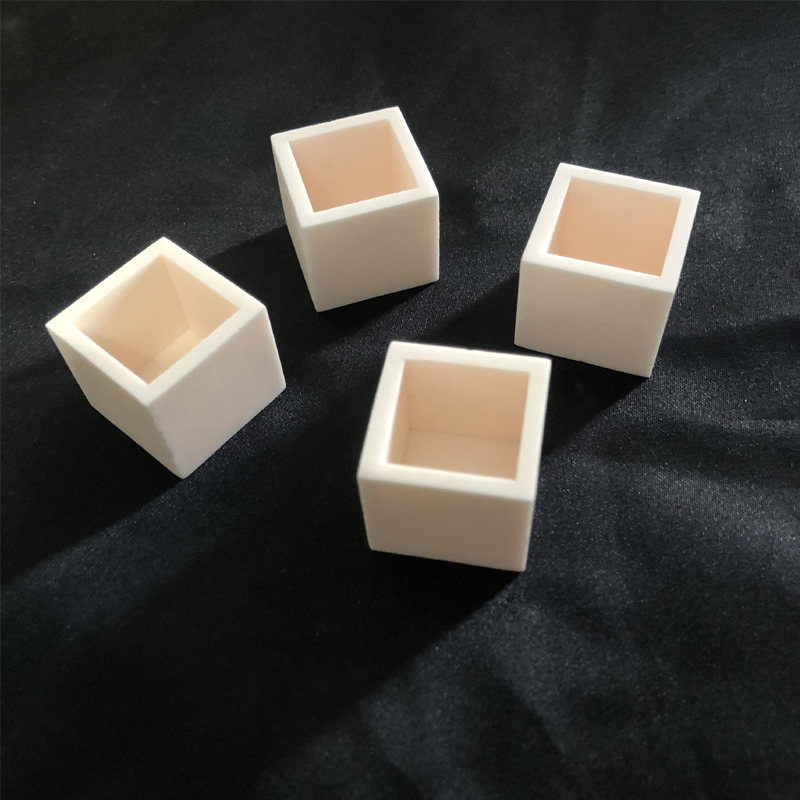

Aluminum Oxide Ceramic Crucible

My factory looking for distributors.

Crucible, as an important part of chemical equipment, is a reaction vessel for melting and refining liquid metal and heating solid-liquid. It is the basis for ensuring the smooth progress of chemical reactions. Historically, crucibles were originally made of clay, and one of the earliest uses of platinum was to make crucibles. But with the development of preparation technology, the crucible can now be made of any material that can melt or change its contents.

No: F11#

Shape: New product small square crucible

Unit price: USD 0.79

The crucible has many types, models and specifications, which can be selected at will, with strong applicability, and can ensure the purity of the material to be smelted. Among them, the ceramic crucible is an important part of the crucible. The ceramic crucible can be divided into alumina crucible, corundum crucible, quartz crucible, zirconia crucible and so on according to the raw materials. It is applied in different occasions according to their respective properties.

Recommended products:

Ceramic beads

2 bores round ceramic beads used in thermocouple could satisfy the turning,gyration,warping etc measurement requirement in complex conditions.

Ceramic parts

It has the characteristics of high temperature resistance, corrosion resistance, thermal shock resistance,

high mechanical strength, excellent electrical performance, etc. It is widely used in industrial equipment manufacturing and other fields.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Other dimensions, price reference table

| 1 | 30*20*15*δ2 | Rectangle | 0.87 |

| 2 | 45*13/11*9 | Boat shape with ears | 0.87 |

| 3 | 48*50/10 | Trapezoid | 5.8 |

| 4 | 50*10*10*δ2 | Rectangle | 0.87 |

| 5 | 80*50*7*δ1.5 | Rectangle | 1.74 |

| 6 | 80*55*15*δ2.5 | Rectangle | 2.18 |

| 7 | 84*13/11*8 | Boat shape with ears | 0.88 |

| 8 | 100*10*10*δ2 | Rectangle | 1.16 |

| 9 | 100*20*20*δ2 | Rectangle | 1.75 |

| 10 | 100*30*30*δ1.5 | Rectangle | 3.05 |

| 11 | 100*40*18*δ2 | Rectangle | 2.34 |

| 12 | 100*50*30*δ4 | Rectangle | 6.77 |

| 13 | 105*22*14*δ2 | Rectangle | 2.33 |

| 14 | 184*123*62*δ5 | Rectangle | 34.78 |

| 15 | 200*100*50*δ2 | Rectangle | 26.11 |

| 16 | 300*36*18*δ3 | Rectangle | 20 |

| 17 | 300*45/30*20*δ2 | Trapezoid | 11.75 |

RFQ

1.Is aluminum oxide used in ceramics?

Aluminum oxide (Al2O3), traditionally referred to as alumina, is the most established of the engineering ceramics. Being strong, hard, chemically inert, and available in tonnage quantities, this material now has a firm commercial standing as an engineering ceramic.

2.Is aluminum oxide ceramic tough?

Alumina Ceramic: What is it? How Is It Made, Products

Alumina ceramic, or aluminum oxide (Al2O3), is an industrial ceramic that has high hardness, is long wearing, and can only be formed by diamond grinding.

3.Is alumina ceramic safe?

Alumina ceramic, composed mainly of aluminum oxide (Al2O3), is widely regarded as safe for various applications due to its biocompatibility, thermal resistance, and electrical insulation properties. Used in medical implants and dental applications, it is well-tolerated by the body.

Alumina purity test report

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.