Industrial Alumina Ceramic High Temperature Furnace Tube/Pipe

- yunxing

- jinzhou

- It depends on the quantity of products

- 3,000-5,000/month(Looking for distributors)

1. Industrial alumina ceramic furnace tubes tubes, typically made from high-purity alumina (Al2O3), exhibit exceptional thermal stability, corrosion resistance, and mechanical strength, making them ideal for use in harsh operating environments.

2. One of the key advantages of industrial alumina ceramic furnace tubes is their ability to withstand extremely high temperatures without undergoing significant deformation or degradation. This characteristic makes them indispensable for processes that involve the production or treatment of materials at elevated temperatures, including sintering, calcination, annealing, and thermal decomposition.

3. Moreover, the exceptional chemical inertness of alumina ceramics ensures compatibility with a wide range of substances, including acids, alkalis, molten metals, and gases. This resistance to chemical attack minimizes contamination and ensures the purity of the processed materials, making alumina furnace tubes particularly well-suited for applications that demand strict quality control and product integrity.

Industrial Alumina Ceramic High Temperature Furnace Tube/Pipe

Advantages of Industrial Alumina Ceramic Tube/Pipe

1. Industrial alumina ceramic furnace tubes tubes, typically made from high-purity alumina (Al2O3), exhibit exceptional thermal stability, corrosion resistance, and mechanical strength, making them ideal for use in harsh operating environments.

2. One of the key advantages of industrial alumina ceramic furnace tubes is their ability to withstand extremely high temperatures without undergoing significant deformation or degradation. This characteristic makes them indispensable for processes that involve the production or treatment of materials at elevated temperatures, including sintering, calcination, annealing, and thermal decomposition.

3. Moreover, the exceptional chemical inertness of alumina ceramics ensures compatibility with a wide range of substances, including acids, alkalis, molten metals, and gases. This resistance to chemical attack minimizes contamination and ensures the purity of the processed materials, making alumina furnace tubes particularly well-suited for applications that demand strict quality control and product integrity.

4. In addition to their thermal and chemical properties, industrial alumina ceramic furnace tubes exhibit remarkable mechanical strength and abrasion resistance, enabling prolonged service life even in demanding operational conditions. Their inherent toughness and durability contribute to cost savings by reducing maintenance downtime and replacement frequency.

5. Furthermore, alumina ceramic furnace tubes offer excellent thermal insulation properties, facilitating precise temperature control and energy efficiency in heating processes. Their low thermal conductivity helps to minimize heat loss and optimize thermal uniformity within the furnace chamber, ensuring consistent and reliable performance.

6. The versatility and reliability of industrial alumina ceramic furnace tubes make them indispensable components in a wide range of industrial applications. From high-temperature heat treatment processes to thermal analysis and materials synthesis, these tubes provide essential support for achieving optimal results and maximizing productivity in diverse manufacturing and research environments.

Application of Industrial Alumina Ceramic Tube/Pipe

Industrial alumina ceramic furnace tubes have a wide range of applications in the industrial field, mainly including the following aspects:

1. High temperature furnace tube application: Industrial alumina ceramic furnace tubes have excellent high-temperature resistance and can usually withstand high temperatures of thousands of degrees Celsius. Therefore, they are widely used in various high-temperature heating equipment, such as high-temperature sintering furnaces, high-temperature melting furnaces, heat treatment furnaces, etc.

2. Chemical industry: In the chemical industry, alumina ceramic furnace tubes are commonly used in various chemical reaction vessels, distillation towers, drying equipment, etc. Due to their good corrosion resistance and ability to withstand the erosion of corrosive substances such as acid and alkali.

3. Semiconductor manufacturing: In the manufacturing process of the semiconductor industry, high-temperature equipment is often used for wafer heat treatment, annealing and other processes. Aluminum oxide ceramic furnace tubes can provide a stable high-temperature environment to ensure the smooth progress of the manufacturing process.

4. Glass industry: In the process of glass production, it is necessary to melt the raw materials. Aluminum oxide ceramic furnace tubes can provide a stable high-temperature melting environment, which helps to improve the efficiency and quality of glass production.

5. Photovoltaic industry: In the production of photovoltaic cells, high-temperature equipment is required for multiple sintering, annealing and other processes. Aluminum oxide ceramic furnace tubes can provide the required high-temperature environment to ensure the manufacturing quality of the cells.

Alumina Tube(open both ends)(slip casting) Specification Table

Number | SPEC: OD x ID |

LENGTH MM |

Number | SPEC: OD x ID |

LENGTH MM | ||

INCH | MM | INCH | MM | ||||

1 | 0.197x0.118 | 5x3 | ≤800 | 32 | 1.126x0.886 | 28.6x22.5 |

≤1800 |

2 | 0.236x0.157 | 6x4 |

≤1300 | 33 | 1.181x0.827 | 30x21 | |

3 | 0.250x0.125 | 6.4x3.2 | 34 | 1.181x0.906 | 30x23 | ||

4 | 0.250x0.157 | 6.4x4 | 35 | 1.260x0.984 | 32x25 | ||

5 | 0.250x0.188 | 6.4x4.8 | 36 | 1.375x1.125 | 34.9x28.6 | ||

6 | 0.276x0.157 | 7x4 | 37 | 1.378x1.063 | 35x27 | ||

7 | 0.276x0.197 | 7x5 | 38 | 1.496x1.181 | 38x30 | ||

8 | 0.315x0.197 | 8x5 | 39 | 1.575x1.181 | 40x30 | ||

9 | 0.354x0.236 | 9x6 |

≤1600 | 40 | 1.654x1.339 | 42x34 | |

10 | 0.375x0.250 | 9.6x6.4 | 41 | 1.750x1.500 | 44.5x38.1 | ||

11 | 0.394x0.236 | 10x6 | 42 | 1.811x1.496 | 46x38 | ||

12 | 0.394x0.276 | 10x7 | 43 | 1.875x1.625 | 47.6x41.3 | ||

13 | 0.433x0.276 | 11x7 | 44 | 1.969x1.575 | 50x40 | ||

14 | 0.472x0.236 | 12x6 | 45 | 2.000x1.750 | 50.8x44.5 | ||

15 | 0.472x0.315 | 12x8 | 46 | 2.250x2.000 | 57.2x50.8 | ||

16 | 0.472x0.355 | 12x9 | 47 | 2.283x1.890 | 58x48 | ||

17 | 0.500x0.250 | 12.7x6.4 | 48 | 2.362x1.96 | 60x50 | ||

18 | 0.500x0.375 | 12.7x9.5 | 49 | 2.500x2.250 | 63.5x57.2 | ||

19 | 0.551x0.394 | 14x10 | 50 | 2.559x2.165 | 65x55 | ||

20 | 0.591x0.394 | 15x10 |

≤1800 | 51 | 2.750x2.500 | 69.9x63.5 | |

21 | 0.630x0.472 | 16x12 | 52 | 2.756x2.362 | 70x60 | ||

22 | 0.669x0.472 | 17x12 | 53 | 2.956x2.561 | 75x65 | ||

23 | 0.688x0.437 | 17.5x11.1 | 54 | 3.000x2.750 | 76x70 | ||

24 | 0.750x0.512 | 19.1x13 | 55 | 3.150x2.675 | 80x68 | ||

25 | 0.787x0.591 | 20x15 | 56 | 3.500x3.125 | 88.9x79.4 |

≤1600 | |

26 | 0.866x0.630 | 22x16 | 57 | 3.543x3.150 | 90x80 | ||

27 | 0.866x0.669 | 22x17 | 58 | 3.937x3.543 | 100x90 | ||

28 | 0.945x0.709 | 24x18 | 59 | 4.000x3.650 | 101.6x93 | ||

29 | 1.000x0.750 | 25.4x19.1 | 60 | 4.331x3.937 | 110x100 |

≤1500 | |

30 | 1.063x0.669 | 27x17 | 61 | 4.500x4.125 | 114.3x105 | ||

31 | 1.063x0.787 | 27x20 | 62 | 4.724x4.331 | 120x110 | ||

Insulation tube (extrusion) Specification Table

Number | 1 Bore tube SPEC: OD x ID | LENGTH MM | |

INCH | MM | ||

1 | 0.031x0.011 | 0.8x0.3 |

≤18500 |

2 | 0.039x0.019 | 1x0.5 | |

3 | 0.059x0.024 | 1.5x0.6 | |

4 | 0.079x0.039 | 2x1 | |

5 | 0.100x0.050 | 2.5x1.3 | |

6 | 0.118x0.059 | 3x1.5 | |

7 | 0.118x0.079 | 3x2 | |

8 | 0.125x0.063 | 3.2x1.6 | |

9 | 0.157x0.079 | 4x2 | |

10 | 0.197x0.118 | 5x3 | |

11 | 0.236x0.118 | 6x3 | |

12 | 0.236x0.157 | 6x4 | |

13 | 0.250x0.125 | 6.4x3.2 | |

14 | 0.250x0.157 | 6.4x4 | |

15 | 0.250x0.188 | 6.4x4.8 | |

16 | 0.276x0.197 | 7x5 | |

17 | 0.315x0.197 | 8x5 | |

18 | 0.354x0.236 | 9x6 | |

19 | 0.374x0.250 | 9.5x6.35 | |

20 | 0.394x0.236 | 10x6 | |

21 | 0.433x0.276 | 11x7 | |

22 | 0.472x0.315 | 12x8 | |

Composition table

| NAME | CONTENT(%) |

| Al2O3 | 99.3-99.5(99.7) |

| SiO2 | 0.3-0.5 |

| CaO+MgO | 0.2-0.3 |

| K2O+Na2O | 0.2-0.35 |

| Fe2O3 | <0.1 |

| OTHER | <0.05 |

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | - |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Cold compressive strength | MPa | 350 |

6 | 20ºC leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600ºC |

8 | Bonding in high temperature | not bonded in 1600ºC | |

9 | 20-1000ºC coefficient ofthermalexpansion | mm.10-6/ºC.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20ºCdirect current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000ºC MΩ | ≥0.08 |

1300ºC MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550ºC | |

15 | Maximum working temperature | ºC | 1800 |

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

FAQ

Q1. Can alumina ceramic furnace tubes be reused after use?

Yes, alumina ceramic furnace tubes can be reused after use, provided they are undamaged and free from contamination. Proper cleaning and inspection are necessary to ensure their suitability for subsequent applications.

Yes, alumina ceramic furnace tubes can be used in high-pressure applications. Their excellent mechanical strength and resistance to thermal and chemical stresses make them suitable for demanding conditions.

Alumina ceramic furnace tubes exhibit good thermal shock resistance, allowing them to withstand rapid temperature changes without cracking or breaking. However, it's essential to choose a tube with suitable thermal shock resistance for specific application requirements.

Yes, many suppliers offer customization options for alumina ceramic furnace tubes. Customization can include adjustments to size, shape, and additional features to meet the specific needs of your application.

The lifespan of alumina ceramic furnace tubes can vary depending on factors such as application conditions, operating temperatures, and maintenance practices. With proper care and usage, these tubes can last several years, providing reliable performance.

Alumina products can withstand up to 1750°C (3182°F).

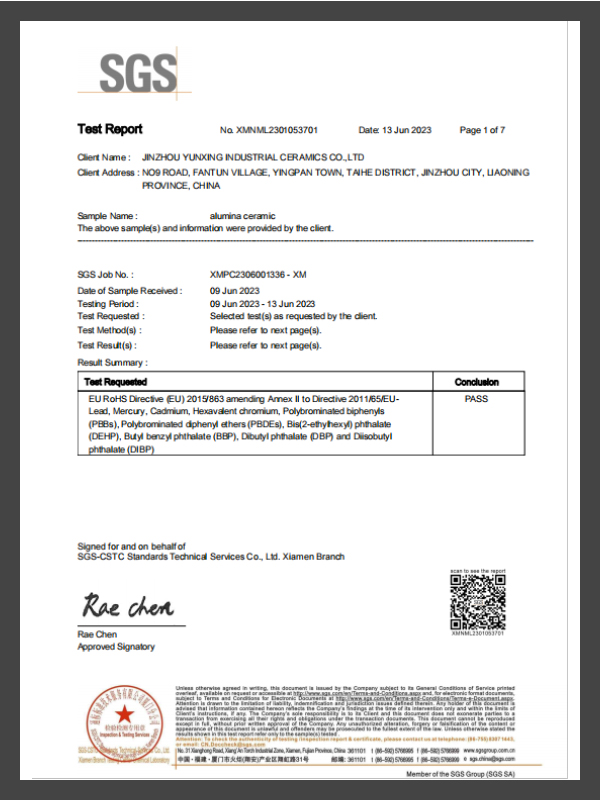

Certification

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.