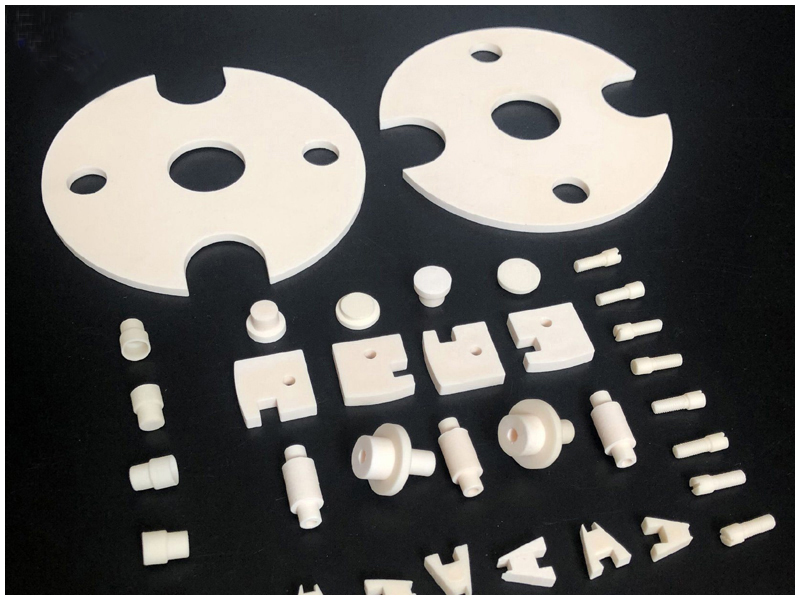

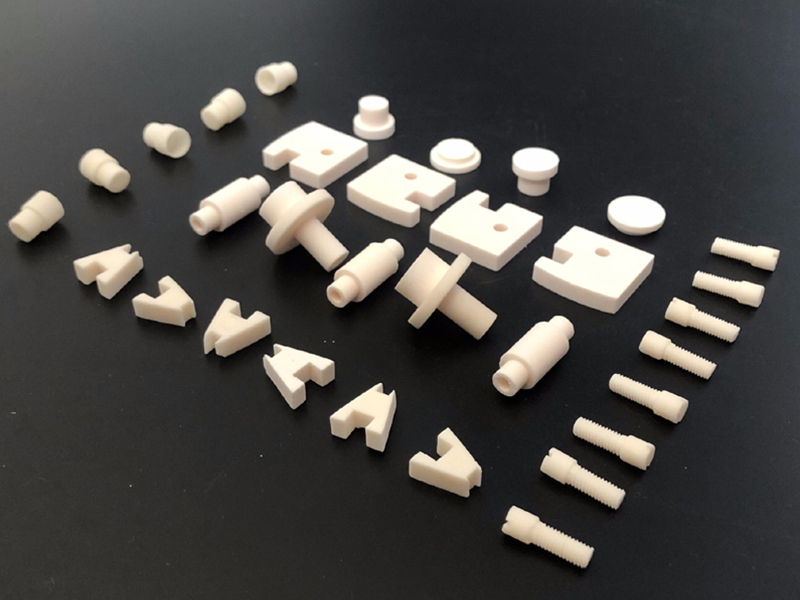

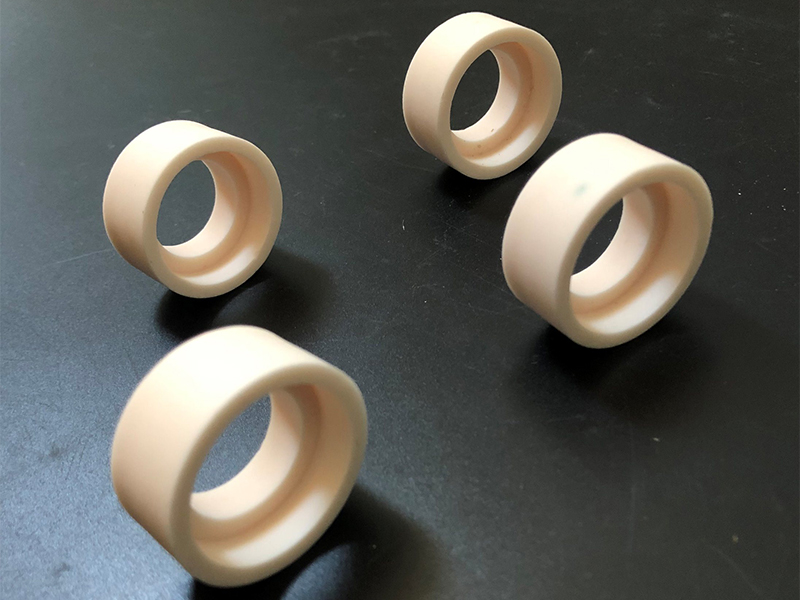

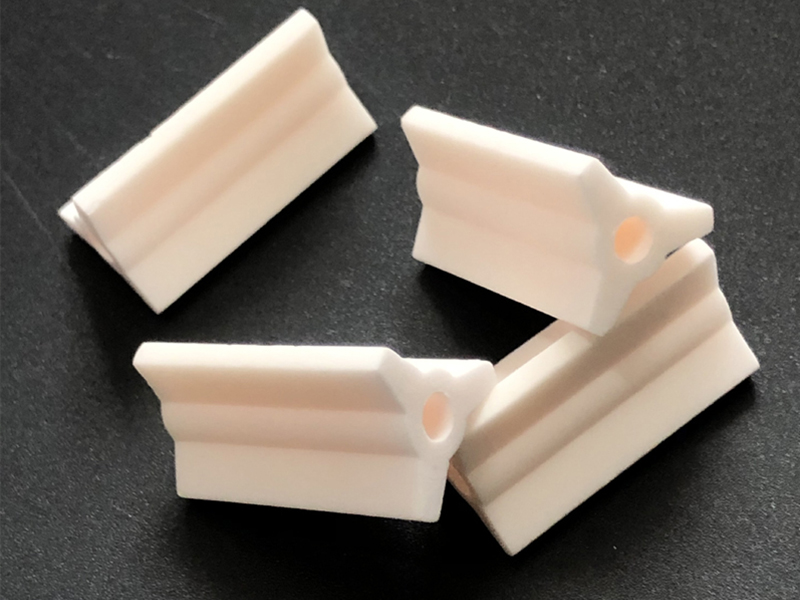

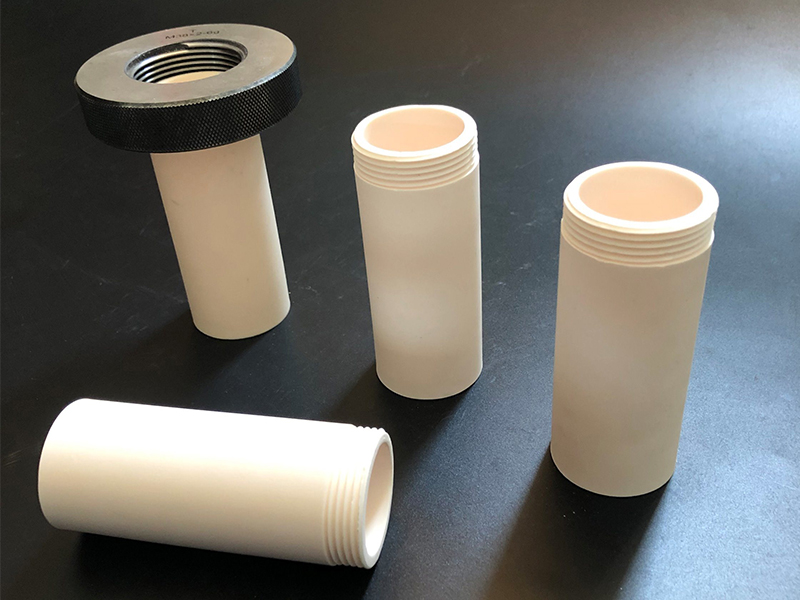

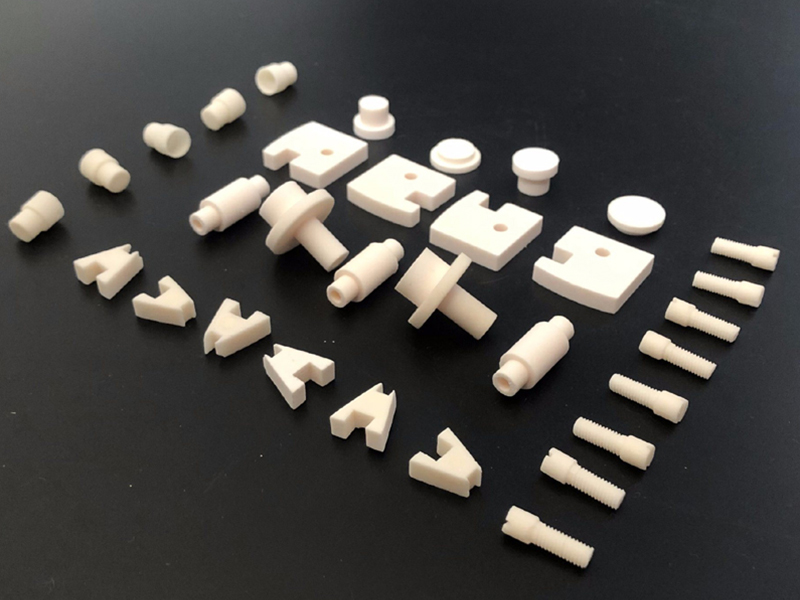

▪ Alumina precision parts made by 99.3%-99.7% high purity alumina

▪ Alumina precision parts have excellent mechanical strength, electrical insulation, and corrosion resistance

▪ Alumina precision parts max working temperature is 1800C

▪ The quality can pass the SGS and DIN43724/DIN43725/DIN40680

▪ Alumina precision parts can accept the custom shape and size without MOQ

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Case

- Factory Show

- Factory Scale

- New factory construction

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search