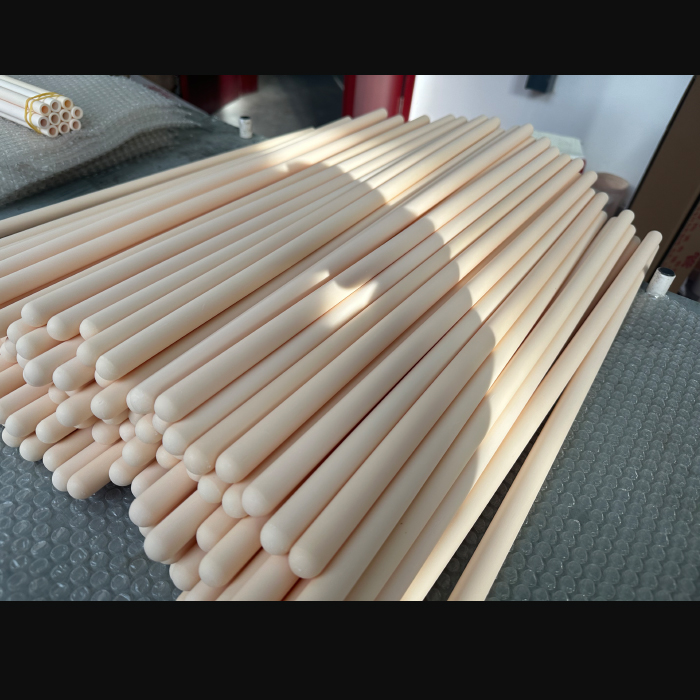

Alumina tube (One end closed)

- yunxing

- china

- According to the quantity ordered

- 3000-5000/month(Looking for distributors)

Alumina ceramic thermocouple protection tubes are available in a variety of sizes with Alumina,being the most commonly used. Ceramic thermocouple protection tubes are typically used to protect Platinum thermocouple elements at high process temperatures above 2200°F.

Alumina tube(One end closed)

General Information

Alumina ceramic thermocouple protection tubes are available in a variety of sizes with Alumina,being the most commonly used. Ceramic thermocouple protection tubes are typically used to protect Platinum thermocouple elements at high process temperatures above 2200°F.

When choosing a ceramic protection tube material, careful consideration should be taken into account in regards to its unique thermal shock characteristics and physical strength.

Alumina

Alumina has a maximum service temperature of 3450°F or 1900°C in both oxidizing and reducing atmospheres. Thermocouple protection tubes made from Alumina are considered to have better mechanical strength (twice the tensile strength of Mullite) and better chemical resistance than Mullite protection tubes. They also have excellent abrasion resistance. Secondary metal tubes can be added for additional protection from mechanical damage. Since Alumina protection tubes are considered to be gas tight, they make excellent primary protection tubes. All tubes, which are used in horizontal installations and at elevated temperatures, should be supported to prevent mechanical breakage. Alumina tubes can be used for primary and secondary protection tubes on Noble Metal (Platinum based) thermocouples. This material has a very low silica content so they will not contaminate Platinum thermocouple elements above (2200°F or 1200°C) as a Mullite protection tube.

Composition - 99.3% Aluminum Oxide.

Specifications

Maximum Service Temperature of 1750°C

Excellent Mechanical Strength

Excellent for Noble Metal Thermocouples

RFQ

What is the difference between ceramic and alumina?

Ceramics are non-metallic, inorganic materials that are typically composed of a combination of metallic and non-metallic elements. Alumina is a type of ceramic oxide, specifically an oxide of aluminum. It is widely used in various applications due to its excellent mechanical, thermal, and electrical properties.

What is alumina ceramic used for?

Everything You Need to Know about Alumina Ceramics

Because of their excellent chemical stability, alumina ceramics are used widely in acid-resistant pump impellers, pump bodies, acid-carrying pipe linings and valves. Aluminum oxide ceramics are used in the manufacture of textile wear parts and knives. This is due to their extreme hardness and wear resistance.

Is alumina ceramic hard?

Alumina is a very hard ceramic that is excellent at resisting abrasion and is ideal for wear-resistant inserts or products.

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.