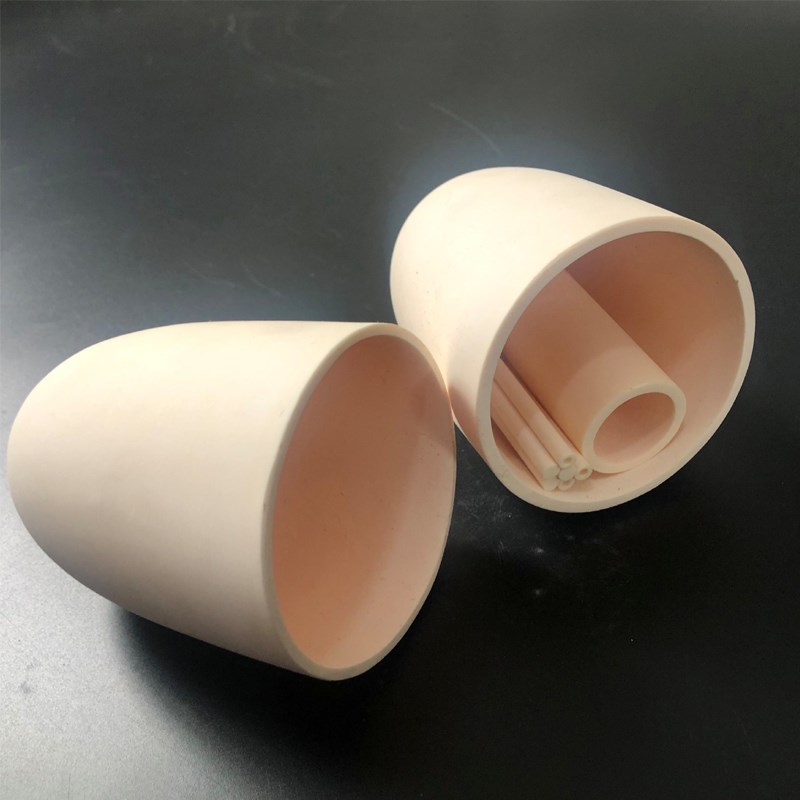

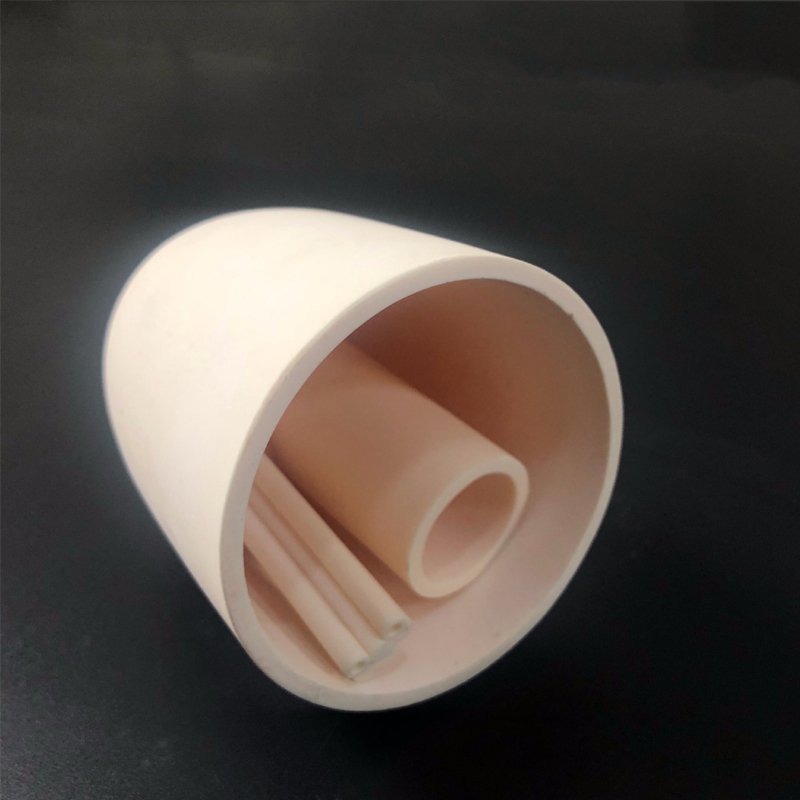

Alumina Conical Crucible

- YUNXING

- China Jinzhou

- 5-30 Days

- 5,000-10,000/month(Looking for distributors)

A. Alumina crucible has good resistance to rapid heat and cold, and is not easy to burst.

B. Alumina crucible has good high temperature insulation and mechanical strength in redox atmosphere.

C. It has high thermal conductivity, low thermal expansion rate, and does not react with air, hydrogen, water vapor, carbon monoxide, etc. above 1700°C.

Alumina Conical Crucible

My factory looking for distributors.

Product Name: Alumina conical crucible

No: 874#

Shape: Conical

Capacity: 270 ml

Size: φ77.2/37.06*φ71*96 mm

The alumina crucible has good resistance to rapid heat and cooling and is not easy to burst. Because the alumina crucible is formed by grouting, the density is high. Corundum crucible has good high-temperature insulation and mechanical strength in oxidizing and reducing atmospheres, high thermal conductivity, low thermal expansion rate, and does not react with air, hydrogen, water vapor, carbon monoxide, etc. above 1700°C.

Recommended products

Protective tube:

For thermocouple external protection tube. insulation,

High temperature resistance, Good air tightness

Big diameter tube:

Used in various industrial furnaces Field, do furnace tube,

And other uses. High temperature resistance, insulation.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Other dimensions, price reference table

NUMBER | L*W*H*WT(MM) | SHAPE | PRICE($) |

1 | 30*20*15*δ2 | Rectangle | 0.87 |

2 | 45*13/11*9 | Boat shape with ears | 0.87 |

3 | 48*50/10 | Trapezoid | 5.8 |

4 | 50*10*10*δ2 | Rectangle | 0.87 |

5 | 80*50*7*δ1.5 | Rectangle | 1.74 |

6 | 80*55*15*δ2.5 | Rectangle | 2.18 |

7 | 84*13/11*8 | Boat shape with ears | 0.88 |

8 | 100*10*10*δ2 | Rectangle | 1.16 |

9 | 100*20*20*δ2 | Rectangle | 1.75 |

10 | 100*30*30*δ1.5 | Rectangle | 3.05 |

11 | 100*40*18*δ2 | Rectangle | 2.34 |

12 | 100*50*30*δ4 | Rectangle | 6.77 |

13 | 105*22*14*δ2 | Rectangle | 2.33 |

14 | 184*123*62*δ5 | Rectangle | 34.78 |

15 | 200*100*50*δ2 | Rectangle | 26.11 |

16 | 300*36*18*δ3 | Rectangle | 20 |

17 | 300*45/30*20*δ2 | Trapezoid | 11.75 |

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

Our packing

1.Full foam board protection in the product box.

2.Carton packing for small products and wooden packing for large products.

Our logistics

1.We will choose the most suitable mode of transportation for you.

2.Ensure safe,convenient and fast delivery of goods.

3.Please contact us in time if the goods are damaged,we will replace them for you.

FAQ

1. Material: Alumina ceramic

2. Lead time: pls confirm the quantities required;

3. Incoterm: FOB, CFR, CIF;

4. Delivery Cost: It is determinated by the destination port;

5. Payment Term: PayPal; T/T;

6. We accept customization.

7.We have professional designers.

8.What is alumina crucible used for?

Used as a material for industrial furnaces due to its ability to maintain its hardness at high temperatures. Used as a protector for high-temperature thermal couples. Used as a material for the chemical industry due to its high corrosion resistance.

9.What is the heating rate of alumina crucible?

Alumina crucibles are sensitive to thermal shock. Try to warm up the furnace chamber slowly. A heating rate of 150°C/hour is recommended for the first 1-1.5 hours so that the crucibles can be evenly heated to reduce the impact of thermal shock. It usually takes about 3 hours to increase to high temperature.