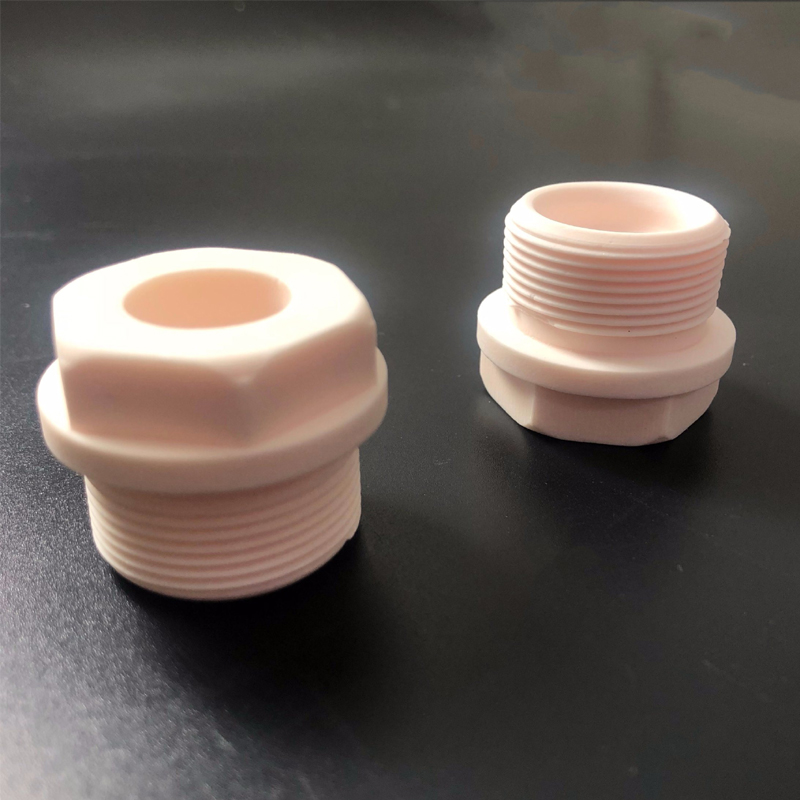

Alumina Ceramic Fasteners/Industrial Fasteners

- yunxing

- china

- According to the quantity ordered

- 3000-5000/month(Looking for distributors)

Alumina Ceramics are the most highly regarded and widely used of the ceramic products.

It is non-conductive, resistant to corrosion, and are perfect for electrical insulation. Alumina Ceramic has proven to be the best ceramic for protection of vital electrical components.

It can be processed as tubing, sheets, bars, rods, discs, and many other forms depending on the requirements of the project.

Alumina Ceramic Fasteners/Industrial Fasteners

Alumina Ceramic Fasteners Properties of Alumina Ceramics

Alumina Ceramics are the most highly regarded and widely used of the ceramic products.

It is non-conductive, resistant to corrosion, and are perfect for electrical insulation. Alumina Ceramic has proven to be the best ceramic for protection of vital electrical components.

It can be processed as tubing, sheets, bars, rods, discs, and many other forms depending on the requirements of the project.

Alumina Ceramic Fasteners application

1. Electronic industry: alumina ceramic fasteners used to insulating screws and electronic equipment, etc.

2. Medical device industry: alumina ceramic fasteners used to manufacture insulating, non-magnetic, environmentally friendly and anti-interference medical equipment

3. Shipping industry: alumina ceramic fasteners used to manufacture acid-, alkali-, and corrosion-resistant ship equipment.

4. Aerospace industry: alumina ceramic fasteners used to manufacture aerospace equipment with insulation, heat insulation and strong anti-interference.

5. Communication industry: alumina ceramic fasteners used to manufacture insulating, non-magnetic and safe communication equipment.

6. New energy industry: alumina ceramic fasteners used to manufacture new energy equipment that is resistant to high temperatures, chemical corrosion and can extend the service life of the equipment.

7. Other industries: such as machinery manufacturing and chemical equipment, etc., any fasteners that require wear resistance, corrosion resistance, and high temperature stability can be made of alumina ceramics.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 |

| >99.3 |

2 | SiO2 |

| — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption |

| 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature |

| not bonded in 1600℃ |

9 |

20—1000℃ coefficient of thermal expansion |

mm.10-6 /℃.m |

8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 |

20℃direct current insulation resistance |

Ohm/cm |

1014 |

13 |

High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance |

| 4 times not cracked in 1550℃ |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

FAQ

What is the difference between ceramic and alumina?

Ceramics are non-metallic, inorganic materials that are typically composed of a combination of metallic and non-metallic elements. Alumina is a type of ceramic oxide, specifically an oxide of aluminum. It is widely used in various applications due to its excellent mechanical, thermal, and electrical properties.

What is alumina ceramic used for?

Everything You Need to Know about Alumina Ceramics

Because of their excellent chemical stability, alumina ceramics are used widely in acid-resistant pump impellers, pump bodies, acid-carrying pipe linings and valves. Aluminum oxide ceramics are used in the manufacture of textile wear parts and knives. This is due to their extreme hardness and wear resistance.

Is alumina ceramic hard?

Alumina is a very hard ceramic that is excellent at resisting abrasion and is ideal for wear-resistant inserts or products.

Authentication certificate

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.