01-12/2026

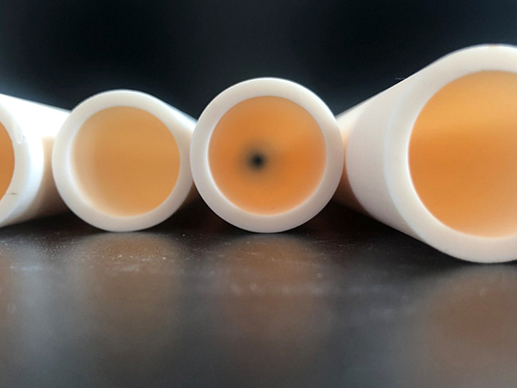

Industrial alumina ceramic tubes in the field of industrial materials have become core components in high-end industrial fields such as chemical, metallurgical, electronic semiconductor, etc. due to their excellent characteristics of high temperature resistance, corrosion resistance, and high hardness.