As an indispensable and crucial component in pipeline systems, flanges are mainly used to connect pipes, equipment, valves and other components. They play important roles such as joining pipelines, ensuring the stability of pipeline systems, achieving sealing of pipeline systems, adapting to different working conditions, and facilitating maintenance.

Through the rational selection and application of flange connections, the safe and stable operation of pipeline systems can be guaranteed, safety accidents such as pipeline leakage and rupture can be effectively prevented, and the working efficiency and economic benefits of pipeline systems can be improved.

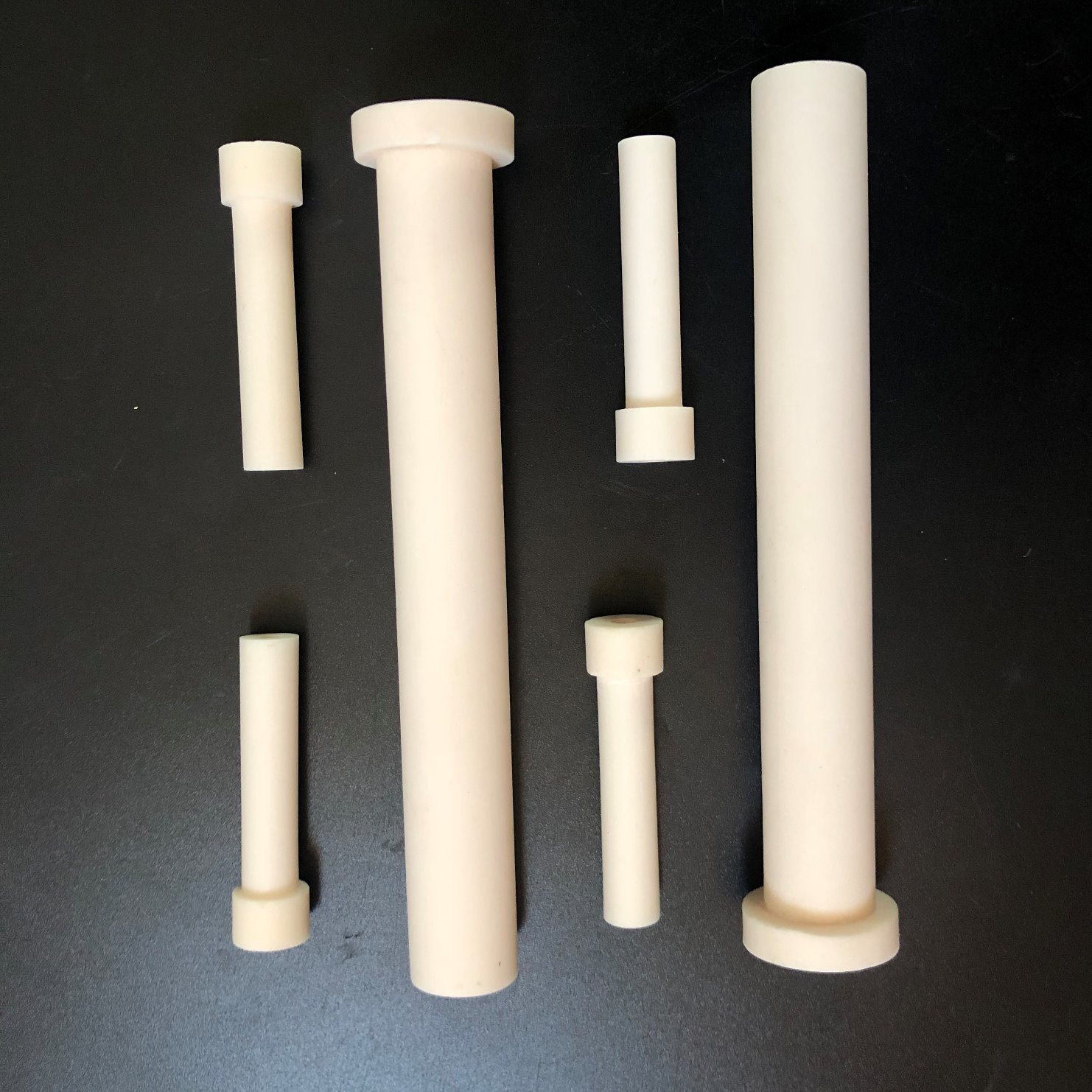

Alumina ceramic flange

Alumina ceramic flanges are mainly composed of two ceramic flange discs, a certain number of bolts and gaskets. They exhibit excellent corrosion resistance, wear resistance, high-temperature resistance, pressure resistance and sealing performance.

With a wide range of applications, alumina ceramic flanges are mainly used in fields such as chemical engineering, petroleum, electric power, biomedicine, aerospace and new energy. They are particularly suitable for medium transportation and treatment under harsh working conditions including high temperature, high pressure, strong corrosion and severe wear.

However, due to their high manufacturing costs and relatively complex production processes, a comprehensive consideration of performance and cost factors is required when selecting ceramic flanges, so as to make a scientific and rational choice based on actual conditions. Meanwhile, certain technical requirements should be observed during installation and maintenance to ensure their safety and reliability.

Will the emergence of alumina ceramic flanges affect the competitiveness of other material flanges?

It will exert a certain impact, but it will not completely replace flanges made of other traditional materials. Instead, it presents a more complementary relationship.

On the one hand, compared with traditional flanges made of materials such as metal and plastic, alumina ceramic flanges boast superior performance advantages and broader application prospects. Under certain special working conditions—such as strong corrosion, high temperature and high pressure, and severe wear—alumina ceramic flanges can better meet engineering requirements, and enhance the safety performance and service life of pipelines and equipment.

On the other hand, alumina ceramic flanges feature relatively high manufacturing costs and complex production processes. Therefore, under conventional working conditions such as low pressure, low temperature and non-corrosive media, traditional flanges made of materials like metal and plastic still maintain strong competitiveness and enjoy steady market demand.

It can be seen from this that alumina ceramic flanges and flanges made of other materials are more of a complementary relationship. In terms of application fields, flanges of different materials can complement and coordinate with each other according to their respective performance and scope of application, so as to jointly meet the requirements of different working conditions and engineering needs. In terms of market competition, the success of various flanges depends on multiple factors such as cost-effectiveness, product reliability and service quality, rather than relying solely on the performance and characteristics of the materials themselves.

In summary, when selecting flange materials for practical applications, it is necessary to comprehensively consider factors such as material performance, scope of application, manufacturing costs, maintenance costs and market competition, and make a scientific and rational choice based on specific working conditions and application requirements.