12-31/2021

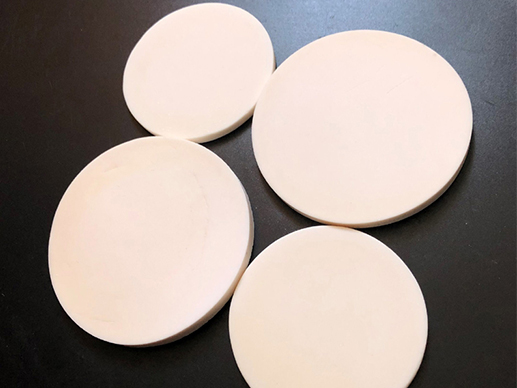

Attracting customers: In order to cater to their preferences, alumina ceramic crucibles provide excellent quality and reliability. These markets require products with excellent performance, durability, and versatility. With its outstanding features, it fully meets their requirements and has become the preferred choice in many industries.