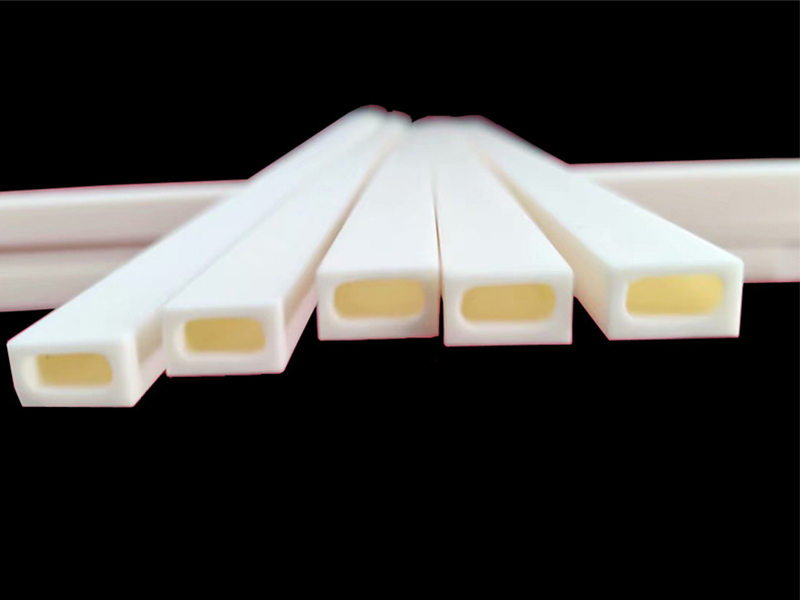

1. Alumina ceramic tubes are resistant to high temperatures and corrosion.

2. Excellent mechanical strength and electrical insulation performance.

3. Accept customized sizes.

4. Large stock and fast delivery.

Send Email

More

Menu

- Home

- Products

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

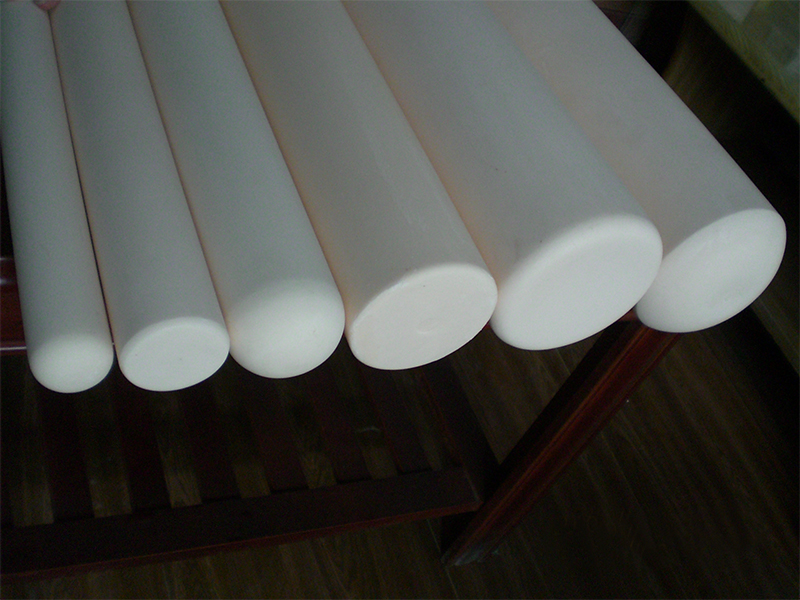

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Product News

- INDUSTRY

- Factory Show

- Factory Scale

- Process Flow

- Customized Process

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search

- Home

- >

- Products

- >

- Alumina Ceramic Tube

- >