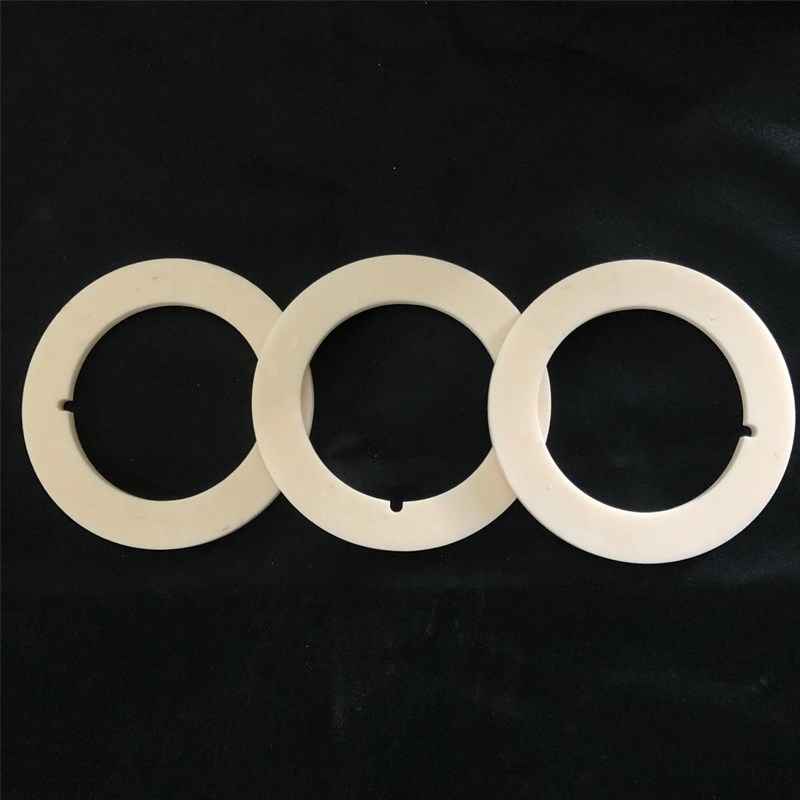

Alumina Ceramic Ring Slice

- YUNXING

- China Jinzhou

- 5-30 Days

- 2,000-3,000/month(Looking for distributors)

A. Alumina ceramics is a very wear-resistant precision ceramic material.

B. It is widely used in electronics, steel, smelting, machinery, coal, mining, chemical, medical, military, aviation, photovoltaic semiconductor and other fields.

My factory looking for distributors

Alumina ceramic ring slice are a type of ceramic parts. Alumina ceramic ring slicehave all the excellent characteristics of alumina products.

The monthly output of Alumina ceramic ring slice is 2,000-3,000, and the shipment time is 5-30 days.

Features of wear-resistant alumina eramic ring slice:

1. Alumina ceramic ring slice Large hardness

Alumina ceramic ring slice Measured by professional research institutes, its Loss hardness is HRA80-90, second only to diamond, and Alumina ceramic ring slice wear resistance far exceeds wear-resistant steel and stainless steel.

2. Alumina ceramic ring slice good wear resistance

Alumina ceramic ring slice after research and determination, its wear resistance is equivalent to 266 times that of manganese steel and 171.5 times that of high-chromium cast iron. According to our ten-year customer follow-up survey, the service life of the equipment can be extended at least ten times under the same working conditions.

3. Lightweight

Its density is 3.5g/cm3, which is only half of steel, which can greatly reduce the equipment load.

4. Wide range of application

Alumina ceramics is a very wear-resistant precision ceramic material, which is widely used in electronics, steel, smelting, machinery, coal, mining, chemical, medical, military, aviation, photovoltaic semiconductor and other fields. Companies with a lot of mechanical equipment wear can choose different types of products according to different needs.

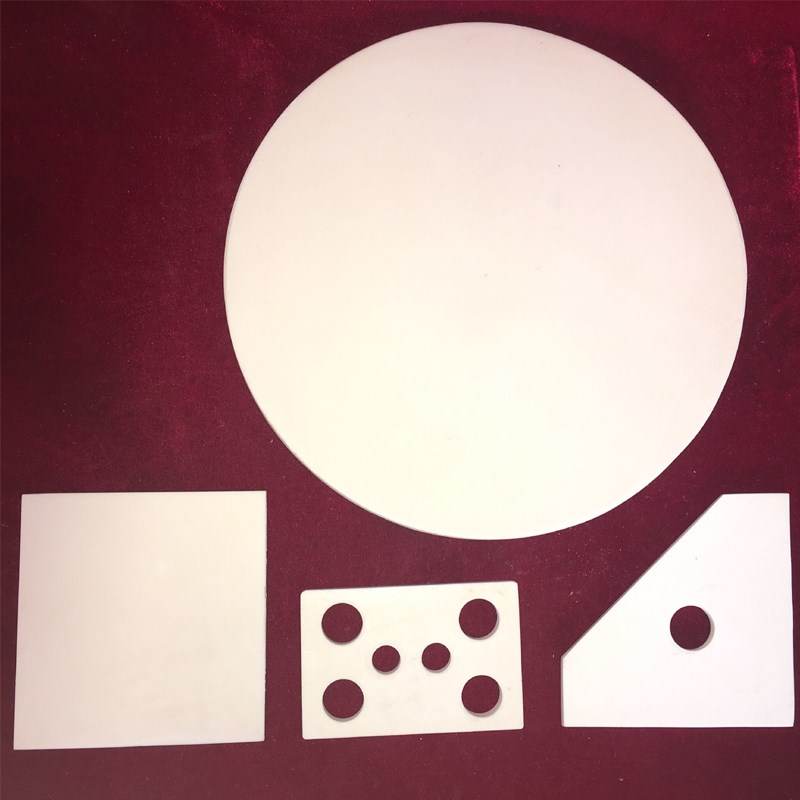

Recommended products:

Ceramic cone crucible:

Fire resistance, corrosion resistance and wear resistance.

Used in metallurgy, chemical industry, papermaking and other industries.

Ceramic tray:

Corrosion resistance, high fire resistance and good chemical stability.

Used in laboratory extraction, burning, mineral, chemical and other industries.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

Alumina purity test report

Our service