Alumina has long played an important role in the national economy as a raw material for aluminum materials and an auxiliary material in traditional industries such as chemical industry and machinery. At present, with the continuous emergence and rapid development of emerging industries such as communications, new energy, and semiconductors, along with an increasingly strong demand for high-performance new materials, some high-end alumina products have taken off. Especially in the two trillion-level markets of new energy and semiconductors, alumina has become a crucial basic material.

▶Two popular markets

①Semiconductor market

With the continuous growth of markets in application fields such as artificial intelligence, 5G communication, the Internet of Things, cloud computing, automotive electronics, robots, and drones, the semiconductor industry market is booming.

According to data from multiple market research institutions, the scale of the semiconductor market achieved significant growth in 2024. For instance, data from the World Semiconductor Trade Statistics (WSTS) shows that the global semiconductor market size in 2024 increased by 19% year-on-year. Among them, the size of China's semiconductor market grew by 20%, accounting for 30% of the global market. WSTS predicts that the global market will grow by 11.2% in 2025 and points out that the industry is expected to reach the sales target of 1 trillion US dollars by 2030.

②New Energy Market

To address the global energy crisis and environmental pollution, advance the low-carbon transformation of energy, and promote the sustainable and healthy development of the new energy industry, countries around the world have introduced policies to support the development of the new energy sector.

In terms of new energy vehicles, since 2021, China's new energy vehicle industry has shown an upward development trend, with annual production and sales growth exceeding 30% for four consecutive years. In 2024, the annual production and sales of new energy vehicles surpassed the 10 million mark for the first time, reaching 12.888 million units and 12.866 million units respectively, with year-on-year growth of 34.4% and 35.5% respectively. The proportion of new energy vehicles in total new car sales reached 40.9%, an increase of 9.3 percentage points compared with 2023. Some institutions predict that the scale of China's new energy vehicle market is expected to reach 2.31 trillion yuan in 2025.

▶Applications of Alumina in the Semiconductor Industry

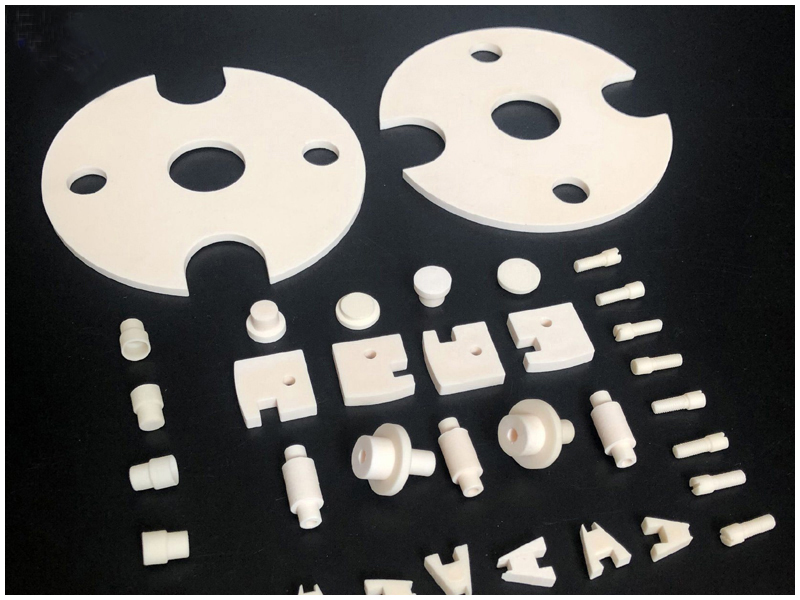

Alumina ceramic components possess excellent properties such as high hardness, high mechanical strength, super wear resistance, high temperature resistance, high resistivity, and good electrical insulation performance. They can meet the complex performance requirements of semiconductor manufacturing in special environments such as vacuum and high temperature, and play an irreplaceable and important role in semiconductor manufacturing production lines. Their applications cover almost all semiconductor manufacturing equipment and are key components of semiconductor production equipment.

Classified by application, alumina ceramic components are mainly divided into circular ring and cylinder types, air flow guiding types, module types, etc.

Circular ring and cylinder types

In the etching process, to reduce contamination of the wafer during plasma etching, high-purity alumina coatings or alumina ceramics with strong corrosion resistance are selected as protective materials for the etching chamber and the inner lining of the chamber.

Air flow guiding types

In the plasma cleaning process, corrosive gases containing halogen elements such as fluorine and chlorine with high reactivity are used. Gas nozzles are usually made of alumina ceramics, which are required to have properties such as high plasma resistance, dielectric strength, and strong corrosion resistance to process gases and by-products. At the same time, they have a precise internal pore structure to accurately control gas flow.

Module type

In the deposition processes, such as advanced technologies like Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), and Chemical Mechanical Polishing (CMP), components made of alumina ceramics are also used for electrostatic chucks, ceramic heaters, polishing tables, polishing plates, chambers, and other processed parts.

▶Applications of Alumina in the New Energy Industry

☛Cathode materials

In the cathode materials of lithium-ion batteries, the surface coating of alumina can effectively improve the capacity retention rate, long-cycle performance, and thermal stability of the cathode materials.

☛Anode materials

Alumina can be coated not only on the separator but also on the surface of the anode. The alumina coating improves the stability of the anode interface, reduces the loss of active lithium, and enhances the charge retention capability and cycling performance of lithium-ion batteries.

☛Electrolyte

Studies have found that adding a certain amount of alumina powder to the electrolyte can effectively improve the conductivity of the electrolyte, reduce the charge transfer resistance, and enhance the electrochemical performance of lithium-ion batteries.

▶Summary

Beyond the above introductions, the applications of alumina in the new energy and semiconductor industries are far more than these. For example, ceramic components such as relays, fuses, and sealing rings in new energy vehicles. In the new energy and semiconductor industries, they are jointly facing thermal management challenges. In addition to participating in thermal management as heat dissipation substrates, alumina is also often used as a thermally conductive filler to make thermal conductive pastes, thermal conductive gels and other heat dissipation materials, playing a key role. In short, alumina materials have broad application prospects in the two popular markets of the new energy and semiconductor industries.