Alumina ceramics, with their unique performance advantages and comprehensive cost-effectiveness, are gradually becoming one of the key material choices for many enterprises to achieve the goal of reducing costs and increasing efficiency. The following will conduct an in-depth analysis of the underlying principles from the aspects of core characteristics, economy, application flexibility and sustainable development:

ⅠPerformance Advantages: Achieving a "Strong" Breakthrough Over Traditional Materials

1.Superior Wear Resistance

Alumina ceramics have a hardness second only to diamond (with a Mohs hardness of up to 9), which is much higher than that of steel. In high-wear operating environments such as mining machinery and cement production, the service life of ceramic components can be 5 - 10 times that of metal materials. This characteristic significantly reduces the frequency of equipment shutdowns for replacement. For example, after a mining group switched to alumina ceramic liners, the equipment maintenance cost was reduced by 40% and the production efficiency was increased by 25%.

2.High Temperature Resistance and Chemical Stability

Alumina ceramics can operate stably in high-temperature environments up to 1600℃ and have excellent resistance to acid and alkali corrosion, making them suitable for extremely harsh working scenarios such as chemical reaction kettles and high-temperature furnaces. Traditional metal materials are prone to deformation and oxidation under high-temperature conditions, while alumina ceramics can effectively prevent the increase in product defect rates caused by material failure.

3.Balanced Insulation and Thermal Conductivity Properties

Alumina ceramics possess high resistivity (>10¹⁴Ω・cm) and moderate thermal conductivity (25W/m・K), making them the preferred material in the fields of electronic substrates and semiconductor packaging. They can effectively reduce circuit losses and improve the operational reliability of equipment.

II. Life Cycle Cost Advantages: Short-Term Investment, Long-Term Profit

1.Consideration of Initial Cost and Comprehensive Benefits

Although the price of a single alumina ceramic product may be higher than that of ordinary metal materials, it has the prominent characteristics of long service life and low maintenance, which can significantly amortize the cost during long-term use. For example, after an automobile manufacturer replaced cemented carbide tools with ceramic tools, although the one-time purchase cost increased by 30%, the service life of the tools was extended by 3 times, the processing efficiency was improved by 20%, and the annual cost saved exceeded one million yuan.

2.Energy Saving and Consumption Reduction Effects

In the field of power transmission, alumina insulators reduce energy loss by 15% compared with traditional porcelain insulators, helping enterprises effectively reduce energy expenditure; in terms of high-temperature equipment applications, their low thermal expansion coefficient can reduce heat energy waste.

III. Processing Customization: Providing Flexible Solutions Adaptable to Diverse Scenarios

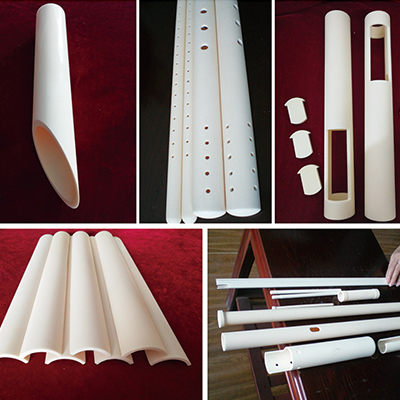

1.Precision Machining Capability

With advanced processes such as dry pressing, injection molding, and 3D printing, alumina ceramics can be processed into precision components with complex shapes (such as electronic substrates with a thickness of only 0.1mm), fully meeting the stringent requirements of high-end fields such as semiconductors and medical equipment.

2.Rapid Response Customization Service

Enterprises can customize ceramic parts according to the specific parameters of equipment, thereby reducing the costs incurred by adaptation and transformation. For example, a customized alumina ceramic guide wheel for a photovoltaic enterprise successfully solved the problem of edge chipping during silicon wafer cutting, increasing the product yield rate from 88% to 97%.

IV. Green Transformation: A Strategic Choice in Line with Environmental Policies

1.Low-Carbon Production Mode

The raw material of alumina ceramics (alumina powder) has a wide range of sources, and the energy consumption of its sintering process is lower than that of metal smelting. A ceramic manufacturer successfully reduced production energy consumption by 30% by applying waste heat recovery technology.

2.Recycling and Compliance Advantages

Waste alumina ceramics can be crushed and reused as raw materials, effectively avoiding the environmental pollution risks that may be caused by waste metal materials. In the context of increasingly stringent environmental policies such as the EU REACH regulations, ceramic materials are more likely to pass environmental audits, thereby reducing the compliance costs of enterprises.

V. Industry Application Cases

New Energy Field: The alumina ceramic rollers used in lithium battery diaphragm coating machines feature corrosion resistance and zero magnetism, which can effectively avoid metal contamination and thus improve the consistency of batteries.

Medical field: The ceramic components used in artificial joints have much better wear resistance than metal materials, which reduces the revision rate of patients by 80% and also lowers the procurement costs of hospitals.

Semiconductor field: High-purity ceramic vacuum chambers can ensure the cleanliness of the chip manufacturing environment and reduce losses caused by equipment shutdowns due to failures.

The principle behind alumina ceramics achieving "cost reduction and efficiency improvement" lies in: extending the service life of equipment by virtue of high performance, reducing hidden costs through low maintenance, improving production efficiency with customization, and avoiding policy risks relying on environmental protection attributes. With the advancement of large-scale production and the continuous iteration and upgrading of technology, their costs are expected to be further optimized, thus becoming a strategic key choice for enterprises to break through the limitations of traditional materials and achieve high-quality development.