In people's impression, ceramics are brittle. With a light drop, a priceless ancient porcelain can instantly "shatter into pieces". But did you know that through modern technology, ceramics have "transformed" and, due to their physical properties, can even serve as bulletproof materials, earning them the reputation of a rising "star" in the field of bulletproofing.

Imagine this: on the battlefield, a tiny bullet can inflict fatal harm on a soldier, yet fragile ceramics can stop a high-speed flying bullet. Where does its "power" come from? Let's step into the world of bulletproof ceramics to find out.

☛ High hardness, composite combination

Bulletproof ceramics are a member of the inorganic non-metallic materials family. Strictly speaking, they are not the same type of material as the porcelain used in our daily lives. As a type of special ceramic, unlike ceramic utensils that are made by shaping local clay into blanks and then firing them, bulletproof ceramics require a series of complex processes for their preparation, including powder preparation, molding, high-temperature sintering, etc. They are a product of the rapid development of modern technologies such as chemistry, metallurgy, and materials science.

The reason why bulletproof ceramics can stop bullets is that they possess extremely high hardness and strength. When a bullet hits high-strength and high-hardness ceramics, it shatters and causes the ceramics to break. This entire process consumes most of the bullet's energy and forms an "inverted pyramid" - shaped damage cone at the point of impact. This is also the typical damage morphology of ceramics after being hit by a bullet.

To enhance the ceramic's ability to withstand multiple impacts, high-strength fiber fabrics are often coated on the ceramic panel to prevent the propagation of cracks caused by bullet strikes. The combination of high-strength and hard ceramics with a rigid backing forms the basic structure of modern ceramic composite armor.

☛ Baptized by war, a shield of life

In the 1960s, U.S. military helicopters and their crew members in the Vietnamese jungles were often attacked and injured by ground light weapons. To reduce battle damage to equipment and casualties among crew members, in 1962, an American aerospace company developed the first composite armor with a hard ceramic front. It glued alumina ceramic blocks to a tough aluminum backplate about 6 millimeters thick to resist fire from 7.62-millimeter armor-piercing bullets. It was during this period that the U.S. military pioneered the large-scale military application of bulletproof ceramics.

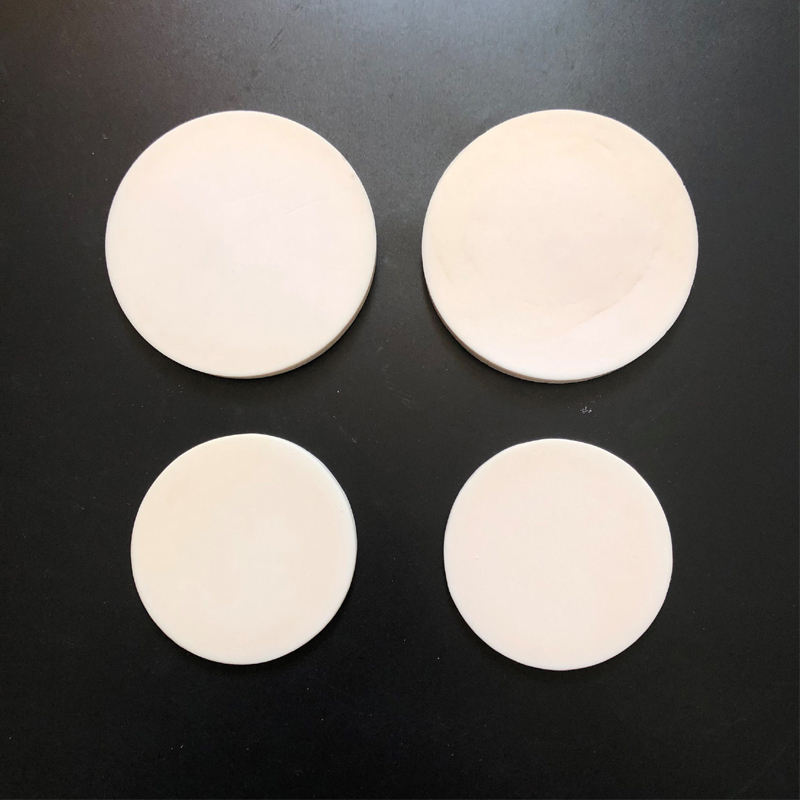

To enhance protective capabilities, scientists came up with the idea of making bulletproof ceramics into insert plates to be used in conjunction with soft body armor, similar to the "heart-protecting mirrors" on ancient armor. This way, it can significantly improve the protection of the human body's core areas while also taking into account the wearer's mobility. Initially, small ceramic pieces were joined together to form the insert plates. With the advancement of technology, people have increasingly adopted whole pieces of ceramics to eliminate the weak points caused by the gaps between small ceramic pieces. Some are even made into curved surfaces to fit the human body. This is also the basic style of current bulletproof insert plates. At present, the preparation technology of bulletproof ceramics has become increasingly mature, becoming a "shield of life" to protect soldiers.

☛ Technology empowers, and further upgrades are made

After decades of development, there are currently many types of bulletproof ceramics widely used, including aluminum oxide, silicon carbide, boron carbide, silicon nitride, titanium boride, etc. Among them, the most common ones are aluminum oxide, silicon carbide, and boron carbide ceramics. With the upgrading of weapon systems, traditional single-phase ceramics can no longer meet actual military needs, especially as the requirements for bulletproof equipment become increasingly higher. Therefore, bulletproof ceramics have begun to develop in the directions of diversification, compounding, and functionalization—

Functionally graded ceramics. Through the design of micro-components, the performance of ceramics undergoes regular and continuous changes. For example, in metal/ceramic composite systems such as titanium boride with metallic titanium, as well as aluminum oxide, silicon carbide, boron carbide, silicon nitride with metallic aluminum, a structural change is formed in the thickness direction, ensuring that the bulletproof ceramics transition from high hardness on the bullet-facing surface to high toughness on the back surface. In this way, it can not only meet the bullet resistance requirements of the armor but also enhance its ability to resist multiple bullet impacts, having a significant advantage in protecting against small and medium-caliber armor-piercing projectiles.

Nanostructured composite ceramics. On the basis of single-phase ceramics, submicron or nanoscale dispersed particles are added to form composite ceramics. For example, silicon carbide-silicon nitride-alumina, boron carbide-silicon carbide, etc., can improve the hardness, toughness and strength of ceramics within a certain range. It is reported that foreign countries are exploring sintering processes that bond nano-scale powders together, which can reduce the ceramic grain size to several tens of nanometers, thereby improving the hardness and strength of the material. This is a major development direction for advanced ceramic armors in the future.

Transparent ceramics. Represented by single-crystal aluminum oxide (sapphire), aluminum oxynitride, and magnesium aluminate spinel, transparent ceramics possess high strength and hardness along with excellent optical properties. Thus, they can replace bulletproof glass and are applied in military equipment such as individual bulletproof masks, missile detection windows, vehicle observation windows, and submarine periscopes. Because they can be used to manufacture large-sized and complex-shaped transparent components at low cost, such ceramics have been listed by many military powers as one of the key photofunctional transparent materials to be developed in the 21st century.

Currently, ceramics are extremely widely used both in the military and in the field of civil technology. It can be predicted that the ancient story of spears and shields will continue to stage wonderful confrontations between strong opponents on future battlefields.