Ceramic membranes, as a material superior to traditional polymer separation membranes, also play a non-negligible role in biomedical pharmacy. After more than a decade of development, China's inorganic ceramic membrane industry has acquired world-leading technologies and achieved a certain scale of application in fields such as biopharmaceuticals, food engineering, and water treatment. This article provides a basic introduction to the application of ceramic membranes in the biopharmaceutical field.

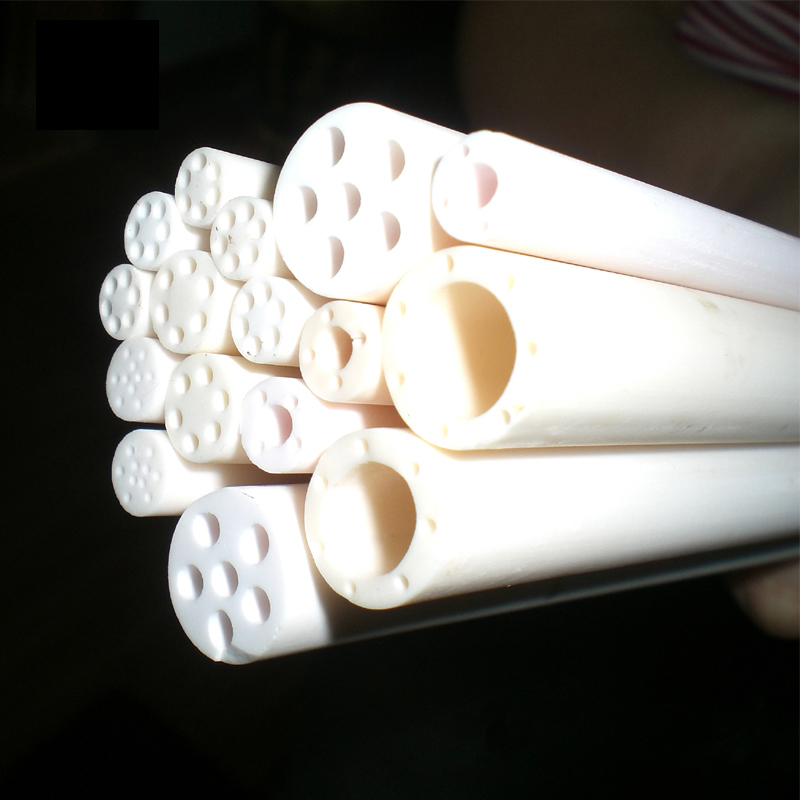

Inorganic ceramic membranes are precision ceramic filtration materials with a porous structure, which are sintered at high temperatures from inorganic materials such asalumina, titanium oxide, and zirconium oxide. They consist of a three-layer structure: a porous support layer, a transition layer, and a microporous membrane layer, presenting an asymmetric distribution. Their filtration precision covers microfiltration, ultrafiltration, and nanofiltration.

The Advantages of Ceramic Membranes in Biomedical Pharmaceutical Applications

① Long service life: Tests have shown that ceramic membranes have a service life 3 to 5 times longer than organic membranes in many applications, while maintaining stable separation performance, which reduces production costs to a certain extent.

② Narrow pore size distribution and high separation precision: Ceramic membranes can reach a nanoscale filtration level, enabling high-magnification concentration. They allow separation and concentration to be carried out in a closed environment at room temperature, thus maintaining the activity of products.

③ Small water washing volume and reduced wastewater discharge: The COD (Chemical Oxygen Demand) in wastewater is significantly reduced, which greatly improves product yield while enabling mycelium recovery. Moreover, no filter aids or coagulants are required, making ceramic membranes highly suitable for applications in the biopharmaceutical field.

④ Excellent chemical stability, acid-resistant, alkali-resistant, and corrosion-resistant: Ceramic membranes have strong antimicrobial properties and can withstand the erosion of various media for a long time, making them suitable for the extraction and separation of various pharmaceutical ingredients in hydrocarbons and various solvents.

⑤ Excellent thermal stability and easy cleaning: Ceramic membranes are very convenient to clean and disinfect, and it is unlikely for the separated system to be contaminated. They can meet the requirements for clean and sterile production processes in pharmaceutical manufacturing, and are also suitable for high-temperature disinfection and steam cleaning processes in the pharmaceutical field.

⑥ Good mechanical properties and high structural stability: Ceramic membranes are made of solid materials. Once installed, they are not easy to fall off or break, can withstand a certain pressure without deformation, will not swell in any solvent, and can resist abrasion caused by solid particles.

Applications of Ceramic Membranes in Biomedicine

① Filtration of Traditional Chinese Medicine (TCM) Extracts: TCM extracts have relatively complex compositions, containing both active ingredients and inactive ingredients, along with a certain amount of toxic ingredients. Compared with the traditional water extraction and alcohol precipitation process, the use of inorganic ceramic membranes for purifying TCM extracts can maximize the extraction of active ingredients. It has advantages such as no phase change, almost 100% retention of target substances, simple and convenient process operation, and low water consumption.

② Separation and Extraction of Enzymes: As an extremely important class of biocatalysts, enzymes play a crucial role in pharmaceutical manufacturing. Traditional separation and extraction methods such as centrifugation, precipitation, dialysis concentration, and desalination yield enzyme solutions with insufficient activity, which require further concentration. These conventional methods also suffer from cumbersome procedures, high energy consumption, high susceptibility to inactivation, and low recovery rates. In contrast, the use of ceramic membrane technology for enzyme separation and extraction can simplify the process. It features simple equipment, high-efficiency processing, and energy conservation, enabling the separation and acquisition of high-concentration bacterial cells within a short time while maintaining enzyme activity.

③ Concentration and Purification of Target Products: Ceramic membrane technology can replace other concentration methods such as vacuum evaporation concentration. When processing crude feed solutions, low-molecular-weight substances (e.g., salts) can pass through the membrane along with water and be removed by filtration. This prevents the inactivation of target products while further concentrating and purifying them, which greatly improves the efficiency of subsequent purification processes, saves energy, shortens the construction period, and significantly enhances product quality and yield.