03-13/2025

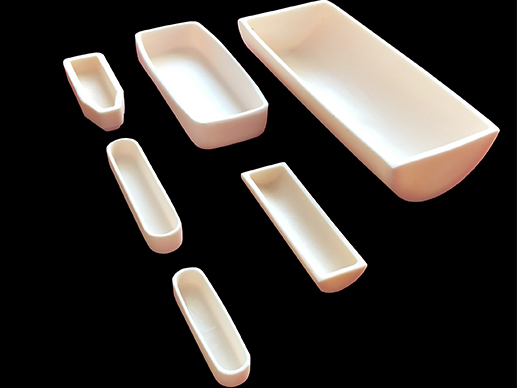

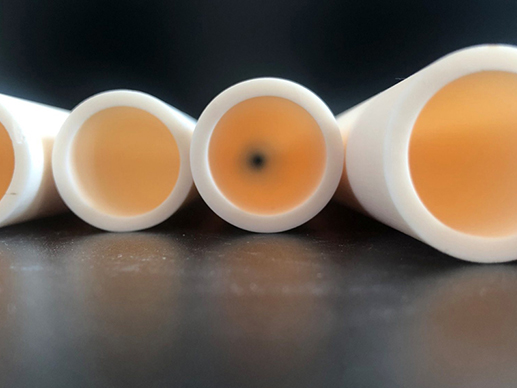

In numerous industrial sectors, the performance of materials under high-temperature conditions is critical. While traditional refractory materials have long been utilized in high-temperature applications, advancements in advanced alumina ceramic materials are now emerging, demonstrating remarkable distinctions compared to conventional alternatives.