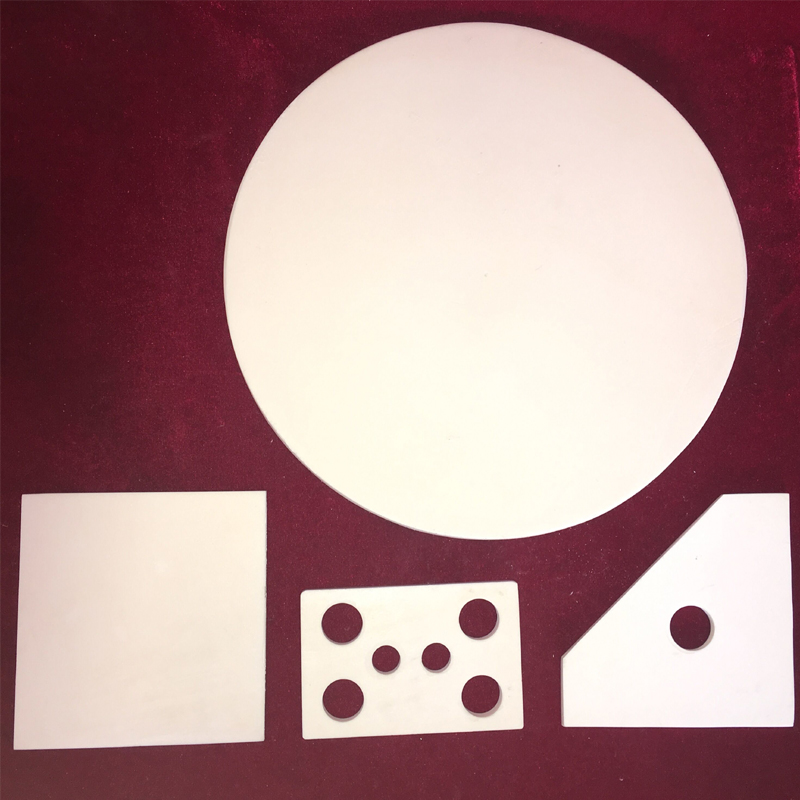

Alumina ceramic plates commonly used in the electronics industry

A well-known electronic device manufacturer in South Korea is facing severe challenges in heat dissipation and circuit stability when developing a new high-performance server. The server integrates a large number of high-power chips internally, which generate a large amount of heat during operation. If not dissipated in a timely manner, it will lead to a decrease in chip performance or even damage, affecting the overall operational efficiency of the server.

The manufacturer has chosen our alumina ceramic plate with 99.3% alumina content as the heat dissipation substrate. The high thermal conductivity of alumina ceramic plates (with a thermal conductivity coefficient of 24W/(m · k)) enables the heat generated by the chip to be quickly conducted to the substrate surface, and then efficiently discharged through a cooling fan. Its high insulation performance (insulation breakdown voltage of 15kV/mm) effectively prevents signal interference and short circuit risks between circuits, ensuring the stable operation of complex circuits inside the server.

In addition, the excellent bending strength (350MPa) of alumina ceramic plates enables them to withstand complex mechanical stresses inside servers. During equipment handling and installation, even if subjected to a certain degree of vibration, the integrity of the circuit can be ensured. After a long period of rigorous testing, servers equipped with alumina ceramic plates have shown excellent performance in terms of heat dissipation and circuit stability, successfully achieving performance upgrades and greatly enhancing the product's market competitiveness, meeting the needs of enterprise users for high-performance and high reliability service providers.