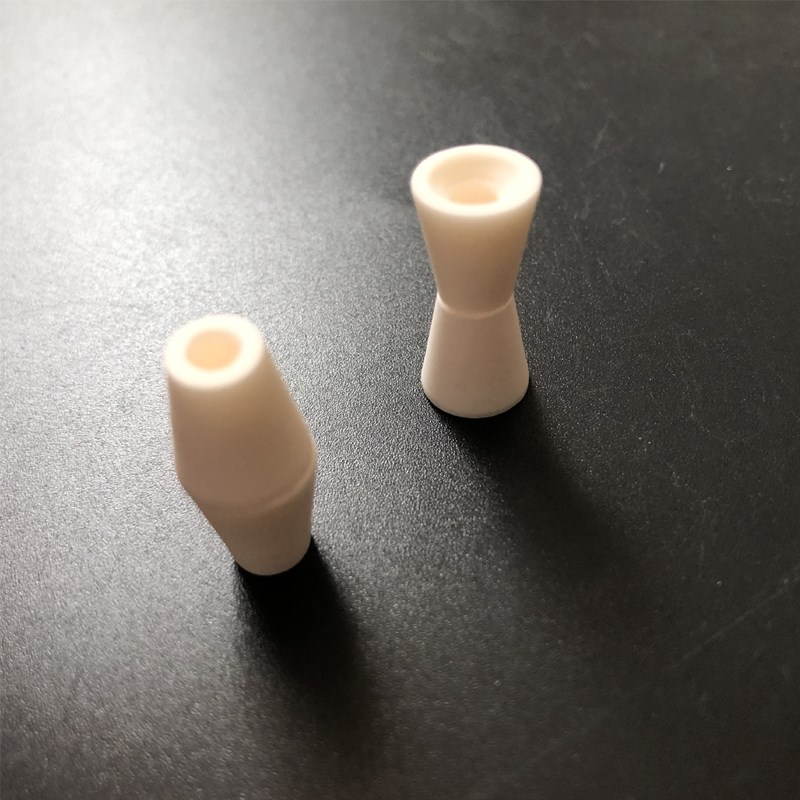

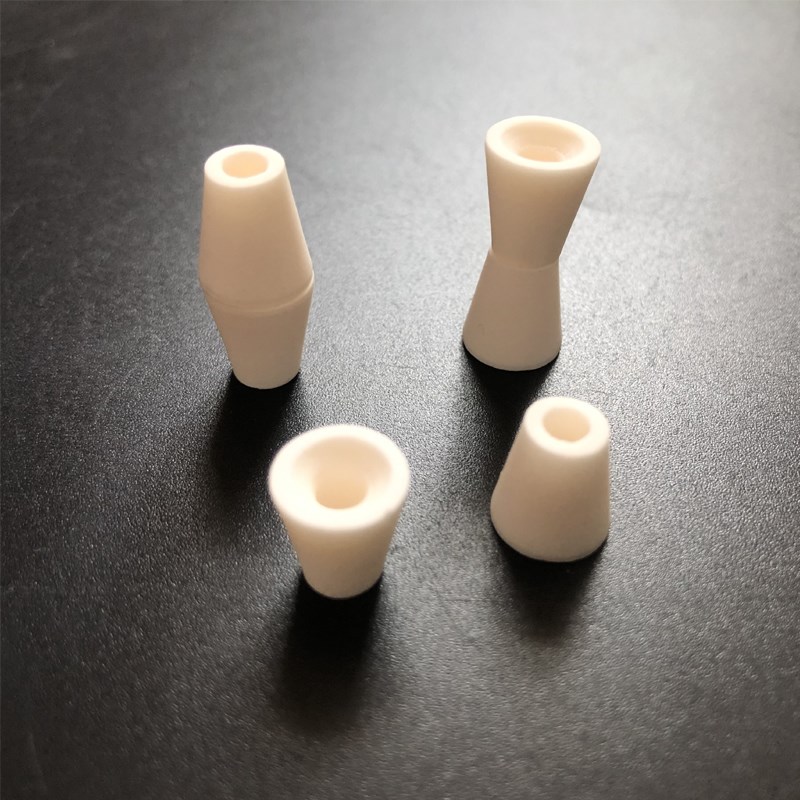

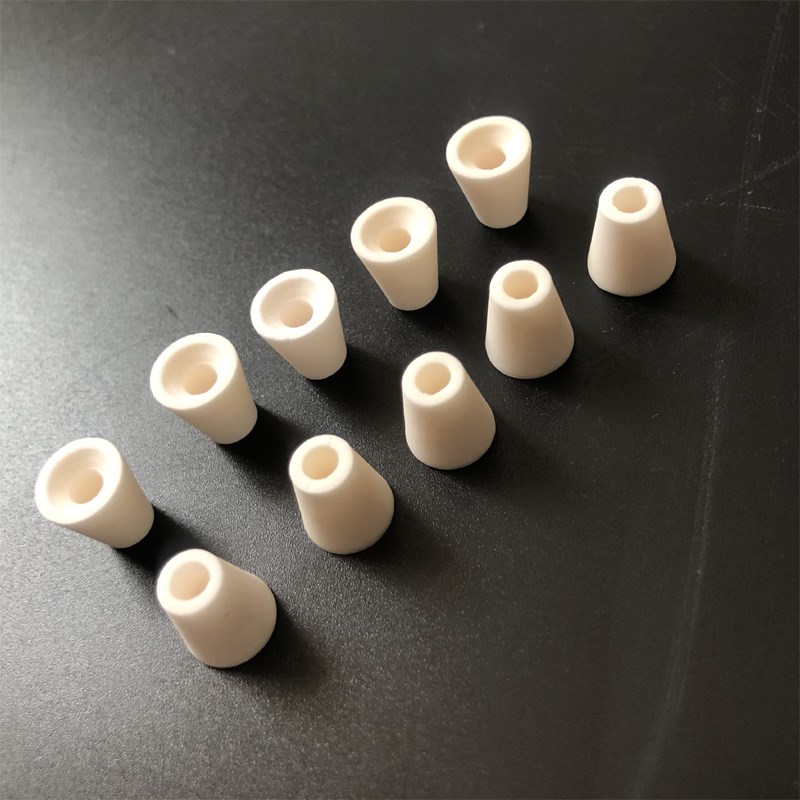

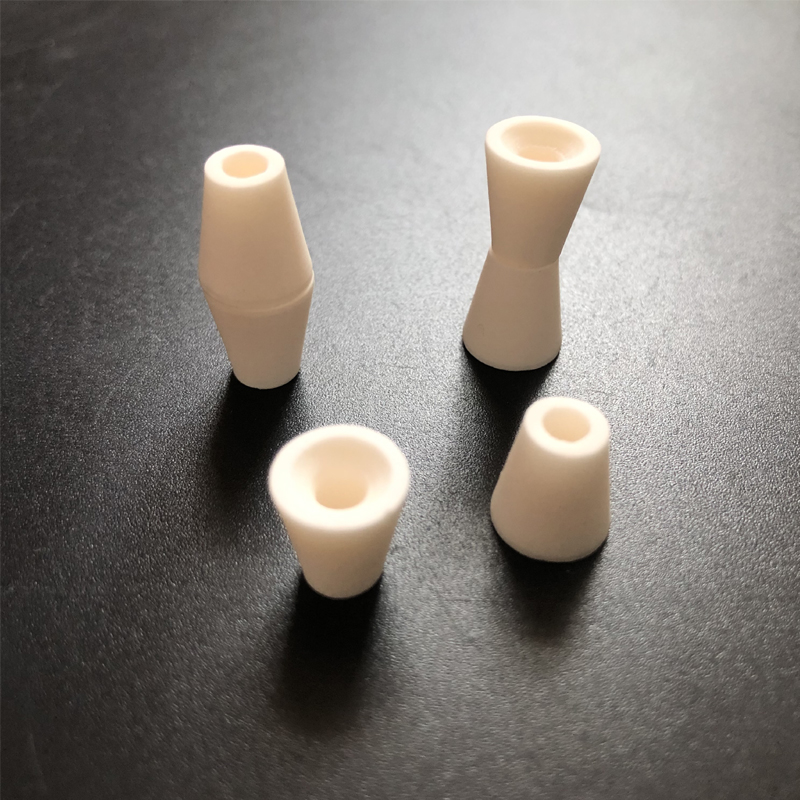

Wear Resistant Alumina Ceramic Beads

- YUNXING

- China Jinzhou

- 5-30 Days

- 10,000-15,000/month(Looking for distributors)

1. The wear resistant alumina ceramic beads porcelain beads can realize the temperature measurement requirements of turning, turning and twisting under thermocouple complicated conditions.

2. With different length and diameter,wear resistant alumina ceramic beads and oval knobs could satisfy any assembly requirement.

Wear Resistant Alumina Ceramic Beads

My factory looking for distributors.

Advantages of wear-resistant alumina ceramic beads

Application of wear-resistant alumina ceramic beads

The high hardness of wear resistant alumina ceramic beads makes it suitable for manufacturing cutting tools, grinding wheels, abrasives, drawing dies, extrusion molds, bearings, etc.

Wear resistant alumina ceramic beads have the characteristics of high melting point and good corrosion resistance. It is also necessary for the production of furnace tubes, crucibles, fibers, thermocouple protection tubes, and other materials.

Wear resistant alumina ceramic beads can also be made into pure metal and single crystal growth crucibles, human joints, artificial bones, sodium vapor lamps, microwave fairings, infrared windows, laser oscillation components, solar cell materials, and battery materials.

Recommended products

Perforated pipe:

A wire sleeve used for thermocouples. High temperature resistance,

insulation, high temperature stability Qualitative good,one-point numerous-temperature

is aiso realizable in porous ceramic insulators.

Ceramic cone crucible:

Fire resistance, corrosion resistance and wear resistance.

Used in metallurgy, chemical industry, papermaking and other industries.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: Alumina ceramic

3. Lead time: pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T;

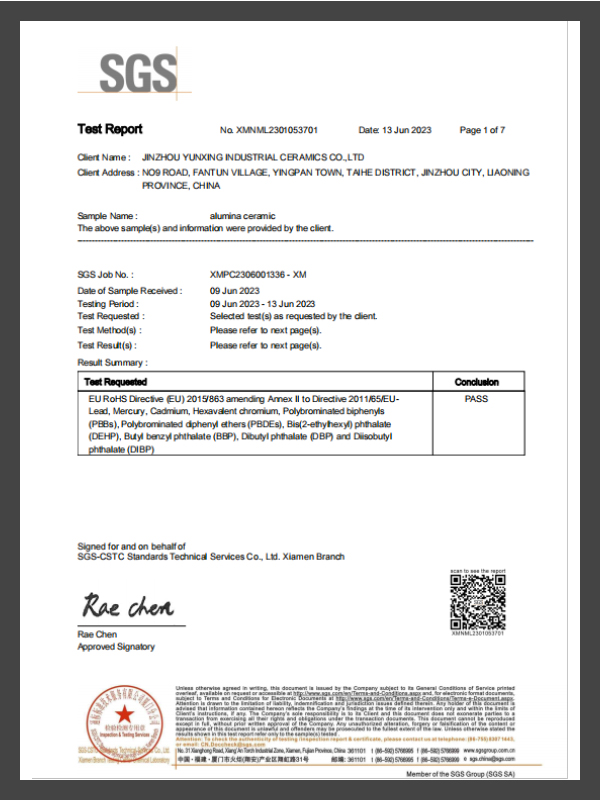

Certification

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.