High temperature piezoelectric ceramics include alkali metal niobate, tungsten bronze structure, perovskite structure and bismuth layered structure. Its Curie temperature is generally below 900℃, which is far from meeting the special needs of ultra-high temperature fields such as aerospace. Therefore, it is very important to study ultra-high temperature piezoelectric ceramics.

Ultra-high temperature piezoelectric ceramics refer to a class of materials with Curie temperature higher than 900℃. At present, the research on piezoelectric ceramic material system with high performance and ultra-high Curie temperature is being carried out at home and abroad, and the development of piezoelectric ceramic material with ultra-high Curie temperature (TC) and good stability has become one of the current research hotspots.

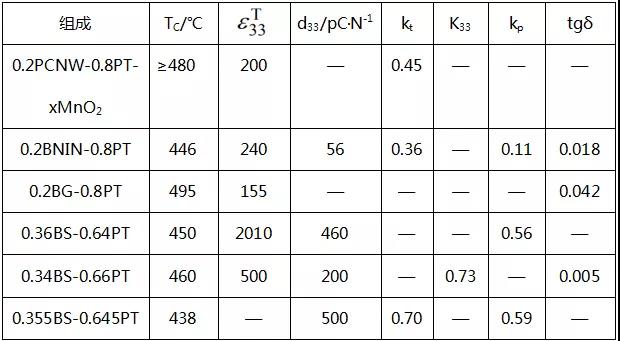

1. perovskite structure high temperature piezoelectric ceramic material

Pure lead titanate is tetragonal perovskite structure at normal temperature, with small dielectric constant, high piezoelectric property, large piezoelectric anisotropy and high Curie temperature (TC=490℃), so it is suitable for working at high temperature. However, as pure lead titanate ceramics are difficult to sinter, when the crystal cools through Curie point, it is easy to crack by itself under the action of internal stress. The large axial ratio makes its coercive field large and difficult to polarize. Therefore, many researchers use doping to form solid melt to solve this problem, and have achieved good research results.

Pb(Zr, Ti)O3(PZT) piezoelectric ceramic material is one of the most widely used and successful piezoelectric ceramic materials due to its excellent piezoelectric properties. It has been widely used in making piezoelectric actuators, sensors, filters, micro-displacers, piezoelectric gyroscopes and other electronic components.

When the molar ratio of zirconium to titanium is Zr: Ti = 53: 47, PZT is located in the MPB region between the three-phase and the four-phase phase. At this time, the iron voltage and electrical properties of the material are better, but the Curie point is about 330℃, and the safe use temperature is lower, so its application can only be limited to the lower temperature region. Research shows that the compound with ABO3 perovskite structure and higher Curie point forms a multi-component solid solution with PZT, which can keep the piezoelectric property stable in a higher temperature range without structural phase change, i.e. with higher Curie point.

2. Tungsten Bronze Structure High Temperature Piezoelectric Ceramics

Tungsten bronze piezoelectric ceramics are a kind of promising electro-optic crystal materials with the characteristics of large spontaneous polarization, high Curie temperature, low piezoelectric dielectric constant and large optical nonlinearity. In addition, niobate tungsten bronze structural compounds have attracted much attention as important high temperature piezoelectric ceramic materials. PbNb2O6 has a tetragonal tungsten bronze structure, a high Curie temperature (TC=570℃), a low quality factor Qm, and is not easy to depolarize when approaching the Curie point. The d33/d31 value is large, and the longitudinal electromechanical coupling coefficient is much larger than the transverse and planar electromechanical coupling coefficients, so it is especially suitable for preparing high temperature resistant transducers.

Lead meta-niobate has great application prospect. There are many kinds of ferroelectrics with tungsten bronze structure. Further modification and theoretical research on ferroelectrics with tungsten bronze structure with high Curie point are important ways to obtain high temperature piezoelectric ceramics with tungsten bronze structure with excellent performance.

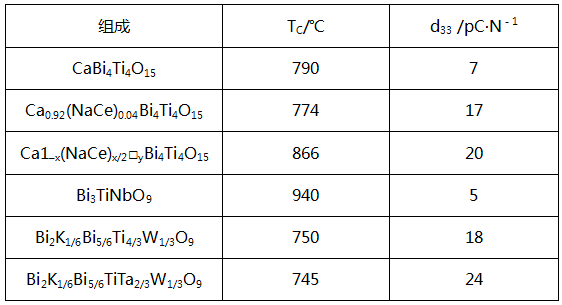

3. bismuth layered structure high temperature piezoelectric ceramic material

Bismuth Layer Structured Ferroelectric (BLSF) is a potential lead-free high temperature piezoelectric ceramic material with the chemical formula (Bi2O3) 2+-(AM-1BMO3M+1) 2-. Compared with lead zirconate titanate ceramics, BLSF has the characteristics of low dielectric constant, sintering temperature and aging rate, high resistivity, obvious anisotropy of mechanical coupling coefficient, high Curie temperature (TC>500℃), good time and temperature stability of resonant frequency, etc. therefore, this kind of materials are especially suitable for making filters and piezoelectric devices in high temperature and high frequency fields.

The application of high-temperature piezoelectric ceramic materials has a very broad prospect and is also a hot research topic at home and abroad. As a high-temperature piezoelectric ceramic material, it must not undergo structural transformation at a higher temperature to affect its piezoelectricity, and its various performance parameters have excellent high-temperature service characteristics, so as to work stably and reliably in a high-temperature state for a long time. At the same time, with the development trend of miniaturization and integration of electronic components, high-temperature piezoelectric thin film materials will also become a research hotspot in the future.