Revolutionizing High-Temperature Applications

The Rise of Alumina Combustion Boats:

In the ever-evolving landscape of industrial ceramics, alumina combustion boats are emerging as a game-changer, offering unparalleled advantages for high-temperature applications. As industries ranging from metallurgy to electronics continually seek materials that can withstand extreme conditions, alumina ceramics have stepped into the spotlight, demonstrating their superiority in durability, thermal stability, and versatility.

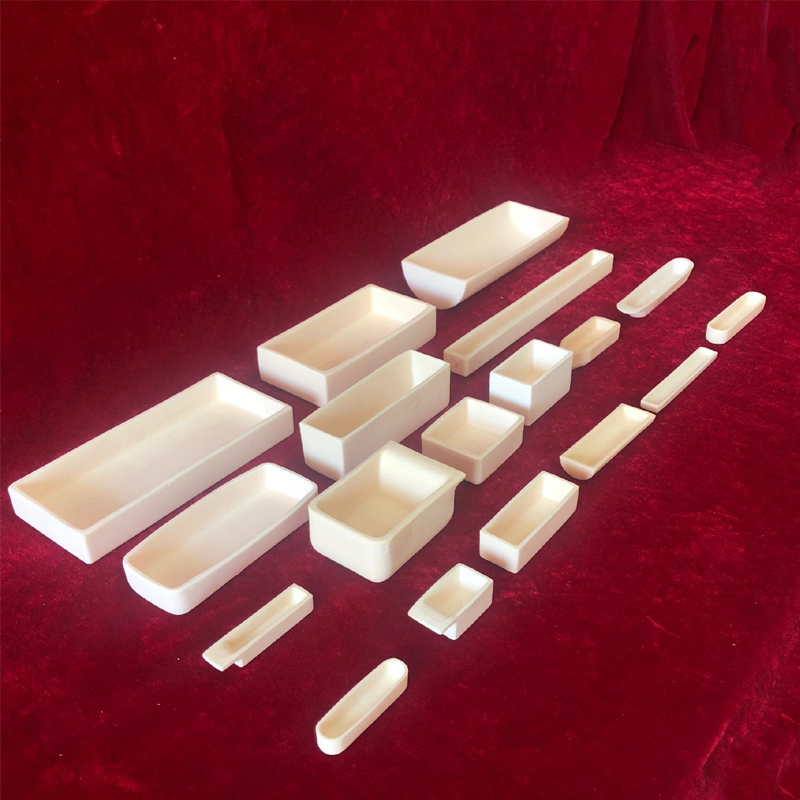

Alumina combustion boats are ceramic containers crafted from high-purity alumina (Al₂O₃). Renowned for their exceptional thermal and chemical resistance, these boats are designed to hold materials during combustion processes at high temperatures. They are commonly used in laboratories and industrial settings where precise and consistent thermal conditions are paramount.

The primary advantage of alumina combustion boats lies in their exceptional thermal stability. Alumina ceramics can withstand temperatures exceeding 1600°C, making them ideal for processes that require sustained high heat. This thermal resilience is complemented by excellent chemical resistance, ensuring that the boats do not react with the materials they contain or the surrounding environment. Additionally, alumina’s mechanical strength ensures that the boats can endure thermal cycling without cracking or degrading, further extending their service life.

Applications Across Industries

The versatility of alumina combustion boats makes them indispensable across various industries:

1. Metallurgy: In metallurgical processes, alumina combustion boats are used to melt and analyze metal samples. Their high melting point and inert nature prevent contamination, ensuring accurate results.

2. Electronics: The electronics industry benefits from alumina's excellent insulating properties. Combustion boats are used in the production of semiconductors and other electronic components that require high-purity environments and precise thermal management.

4. Pharmaceuticals:Alumina combustion boats are used in the synthesis of pharmaceutical compounds, where high-purity conditions and precise temperature control are critical.

5. Environmental Testing: For environmental studies, alumina combustion boats are employed in the analysis of soil and air samples. Their chemical resistance ensures that the samples remain uncontaminated, providing accurate data for research and regulatory purposes.

Recent advancements in ceramic manufacturing technology have further enhanced the performance of alumina combustion boats. Innovations in sintering processes have led to the development of boats with improved density and reduced porosity, which translates to even greater mechanical strength and resistance to thermal shock.

Sustainability and Future Prospects

As industries worldwide strive for sustainability, alumina combustion boats offer an environmentally friendly alternative to traditional materials. Their long service life reduces the frequency of replacement, minimizing waste. Furthermore, the high recyclability of alumina ceramics aligns with the growing emphasis on circular economy principles, promoting resource efficiency and environmental responsibility.

Looking ahead, the demand for alumina combustion boats is expected to rise as more industries recognize their benefits. Ongoing research and development efforts are likely to yield even more advanced ceramic formulations, expanding the potential applications of alumina boats in emerging fields such as renewable energy, space exploration, and advanced manufacturing technologies.

In summary, alumina combustion boats are revolutionizing high-temperature applications across a wide range of industries. Their superior thermal stability, chemical resistance, and mechanical strength make them an invaluable asset for processes that demand precision and durability. As technological advancements continue to enhance their performance and sustainability, alumina combustion boats are poised to play a pivotal role in the future of industrial ceramics, driving innovation and efficiency in high-temperature applications.