Ceramic Substrates with Different Materials

Ceramic Substrates with Different Materials

In recent advancements in electronics and engineering, ceramic substrates play a crucial role in various applications. Different materials are used to manufacture these substrates, each offering unique properties and advantages. In this comparative analysis, we delve into the characteristics of alumina, silicon nitride, and zirconia ceramic substrates, highlighting their applications and advantages.

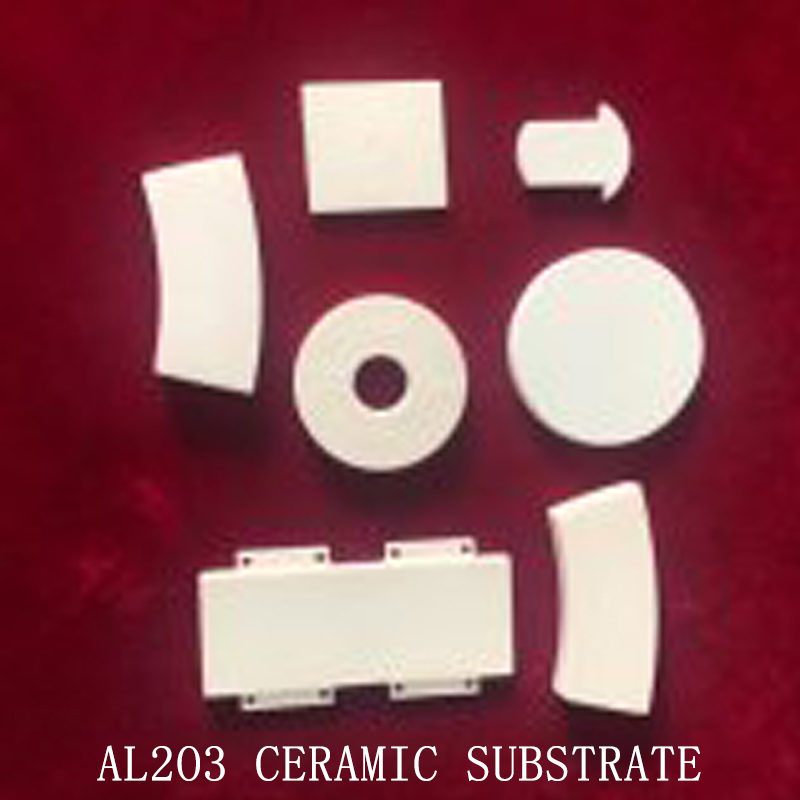

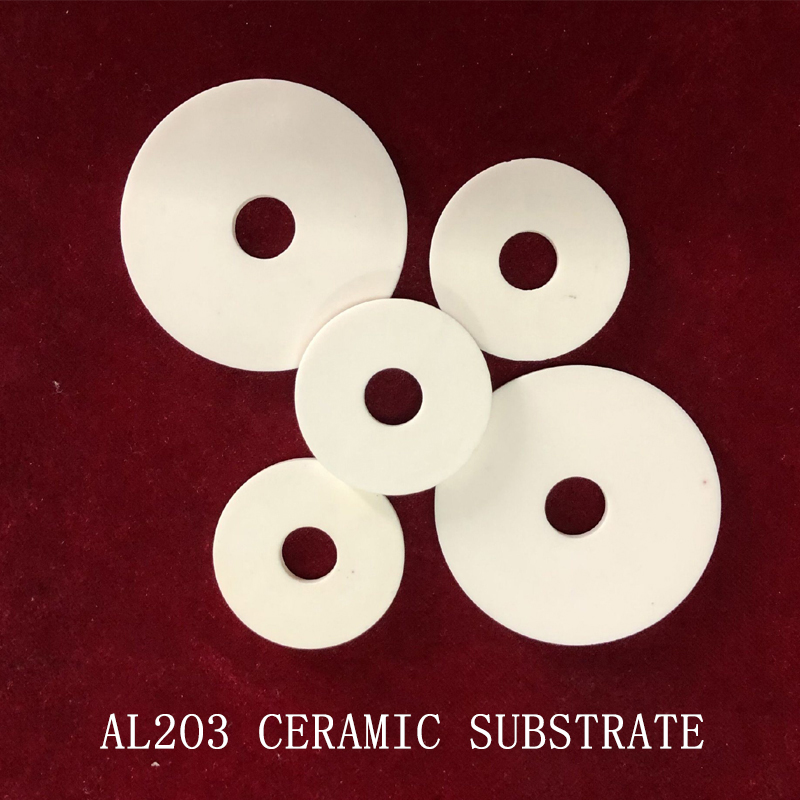

Alumina ceramic substrates, known for their high thermal conductivity and excellent mechanical strength, are extensively used in the electronics industry. They provide a stable platform for electronic components, ensuring efficient heat dissipation and reliability in harsh operating conditions. Alumina substrates are favored in power modules, LED lighting, and semiconductor devices due to their cost-effectiveness and compatibility with manufacturing processes.

Silicon nitride ceramic substrates stand out for their exceptional thermal shock resistance and low thermal expansion coefficient. These properties make them ideal for applications requiring high-temperature stability and reliability, such as automotive sensors, aerospace components, and high-power electronics. Silicon nitride substrates offer improved performance in demanding environments, making them a preferred choice in critical systems.

Zirconia ceramic substrates, characterized by their high strength, toughness, and chemical stability, find applications in biomedical devices, cutting tools, and wear-resistant components. Zirconia's biocompatibility makes it suitable for implants and dental restorations, while its wear resistance makes it valuable in industrial settings. Zirconia substrates contribute to enhanced durability and performance in demanding applications, ensuring long-term functionality.

Each type of ceramic substrate brings distinct advantages to various industries, catering to specific requirements and performance criteria. Manufacturers and designers consider factors such as thermal properties, mechanical strength, chemical resistance, and cost-effectiveness when selecting the most suitable substrate for their applications. As technology continues to evolve, ceramic substrates will play an increasingly vital role in advancing electronic, automotive, aerospace, and medical technologies.