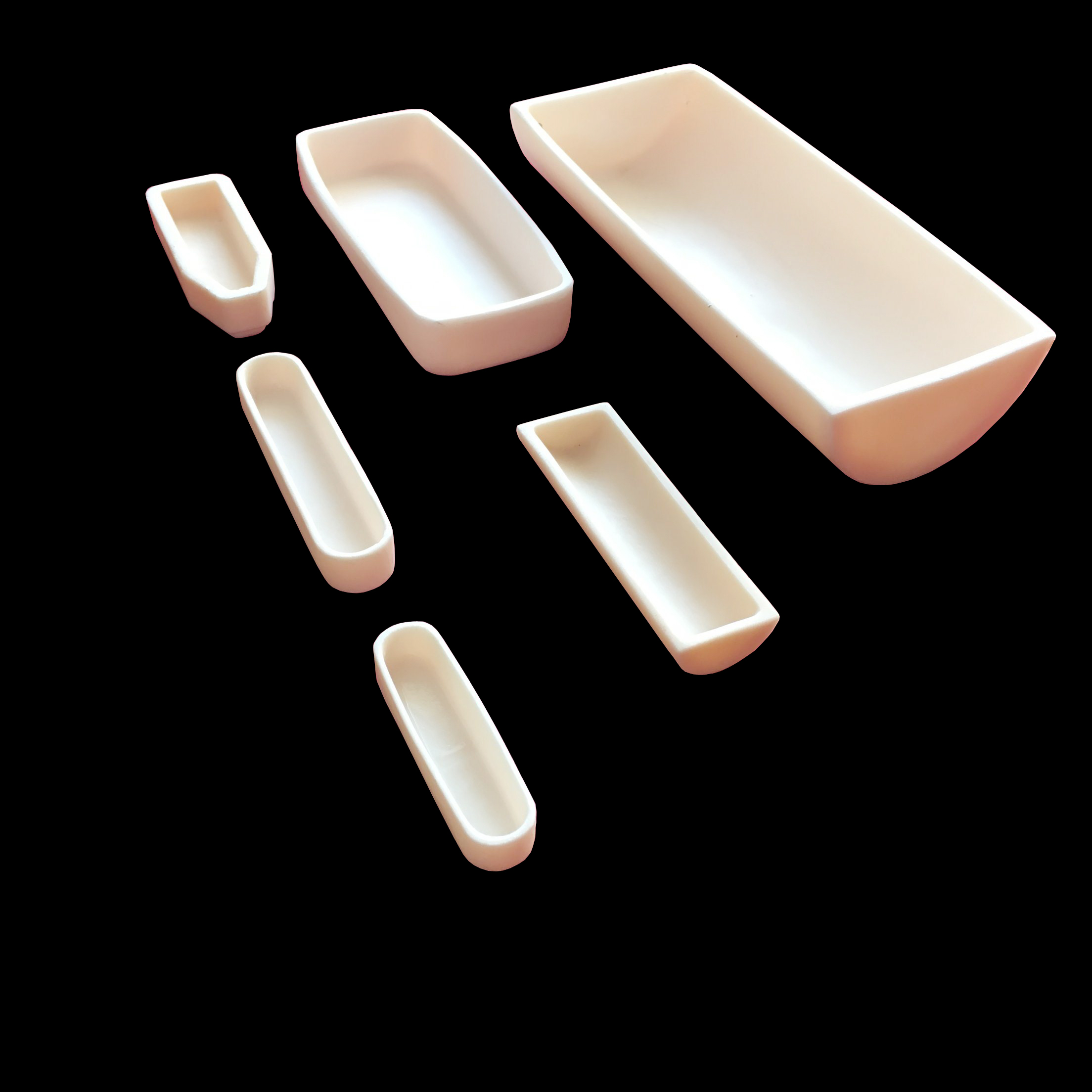

Alumina Crucible Boat

- yunxing

- china

- According to the quantity ordered

- 2000-5000/month(Looking for distributors)

Aluminum oxide crucible ships have high hardness, high temperature resistance, chemical resistance, high melting point, corrosion resistance, and excellent chemical stability.

Alumina Crucible Boat

Aluminum oxide crucible ships have high hardness, high temperature resistance, chemical resistance, high melting point, corrosion resistance, and excellent chemical stability.

Advantages

1. High temperature resistance:1600℃ in long use,1800℃ in short use. This makes it an ideal solution for various thermal processing applications.

2. Excellent thermal shock resistance: Alumina ceramic crucibles have excellent thermal shock resistance, which means they can withstand rapid changes in temperature without cracking or breaking.

3. Non-reactive: Alumina ceramic crucibles are non-reactive, which means they won't react with the substances being heated, melted or cast inside them, ensuring the purity of the final product.

4. Corrosion and Chemical Resistance: The ceramic material used in the crucible exhibits excellent chemical resistance and resistance to corrosion. As a result, it can handle harsh chemicals and acids that might otherwise damage other materials.

5. Minimal Thermal Expansion: The square alumina ceramic crucible has minimal thermal expansion, which means that it will maintain its shape and size at high temperatures, avoiding any potential risks of

Applications of alumina crucible boats

Alumina crucibles and alumina crucibles boats are used as containers for material products for analysis and firing in various industries, such as coal analysis, metal analysis and melting, chemical material analysis and firing, glass analysis and melting. Analysis and firing of rare earth and other raw materials and minerals, firing of high-temperature ceramic lamps, melting of single crystal raw materials and other industries.

Alumina crucible boats size | |||||||||

Item NO. | Length mm | Width mm | Height mm | Volume (mm) | Item NO. | Length mm | Width mm | Height mm | Volume (mm) |

175# | 30 | 20 | 15 | 5 | 076B | 50 | 10 | 10 | 2 |

113A | 62 | 32/22 | 16 | 18 | 161# | 65 | 65 | 65 | 180 |

154# | 80 | 50 | 7 | 20 | 171# | 80 | 55 | 15 | 47 |

076A# | 100 | 10 | 10 | 5 | 075# | 100 | 20 | 20 | 28 |

155# | 100 | 30 | 30 | 75 | 114# | 100 | 40 | 18 | 55 |

226# | 105 | 22 | 14 | 22 | 227# | 184 | 123 | 62 | 1120 |

138# | 300 | 36 | 18 | 132 | 113B# | 300 | 45/30 | 20 | 140 |

254# | 200 | 100 | 50 | 770 | 273# | 84 | 13/11 | 8 | 7 |

274# | 45 | 13/11 | 9 | 5 | 297# | 48 | 50/10 |

| 19 |

303# | 100 | 50 | 30 | 100 | 341# | 150 | 35 | 25 | 86 |

338# | 100 | 20 | 20 | 28 | 344# | 100 | 35 | 20 | 46 |

355# | 60 | 30 | 20 | 22 | 359# | 130 | 130 | 60 | 793 |

360# | 145 | 145 | 12 | 128 | 372# | 60/10 | 30 | 20 | 20 |

373# | 60/10 | 50 | 30 | 63 | 382# | 175 | 90 | 26 | 254 |

396# | 100 | 100 | 17.5 | 100 | 414# | 250 | 100 | 70 | 1400 |

415# | 250 | 56 | 50 | 497 | 440# | 250 | 46/15 | 15 | 65 |

444# | 50 | 20 | 20 | 13 | 477# | 70 | 36 | 17 | 27 |

493# | 44 | 33 | 17 | 16 | 507# | 52 | 31 | 6 | 5 |

514# | 120 | 60 | 17 | 66 | 515# | 120 | 60 | 14 | 50 |

523# | 105/80 | 18/14 | 12 | 15 | 526# | 200 | 20 | 15 | 30 |

539# | 150 | 150 | 70 | 1275 | 429# | 69 | 22 | 11 | 12 |

575# | 200 | 100 | 40 | 600 | 591# | 313 | 45 | 30 | 335 |

606# | 76.2 | 12.7 | 12.7 | 7.5 | 614# | 120 | 83 | 53 | 385 |

630# | 160 | 160 | 50 | 1015 | 636# | 50 | 40 | 20 | 27 |

643# | 170 | 170 | 27 | 370 | 673# | 75 | 15 | 10 | 6 |

678# | 190 | 190 | 80 | 2430 | 689# | 101.6 | 38.1 | 21.08 | 58 |

695# | 200 | 200 | 50 | 1620 | 707# | 114.3 | 76.2 | 9.6 | 470 |

644# | 120 | 80 | 22 | 160 | 662# | 64 | 64 | 60 | 210 |

718# | 90 | 17 | 11.5 | 9 | 724# | 120 | 30 | 20 | 48 |

728# | 100 | 35 | 15 | 35 | 747# | 50 | 12 | 10 | 3 |

776# | 64 | 38 | 20 | 34 | 791# | 48 | 30 | 24 | 16 |

796# | 88.9 | 88.9 | 44.45 | 260 | 803# | 130 | 80 | 15 | 97 |

799# | 188 | 140 | 42 | 850 | 822# | 110 | 70 | 35 | 180 |

825# | 50 | 29 | 28 | 30 | 829# | 300 | 65 | 30 | 460 |

837# | 300 | 60 | 30 | 410 | 838# | 108 | 45 | 19 | 68 |

849# | 150 | 15 | 10 | 12 | 871# | 76 | 76 | 21 | 46 |

879# | 83 | 52 | 6.5 | 17 | 886# | 130 | 90 | 140 | 1300 |

889# | 100 | 100 | 27 | 180 | 890# | 120 | 60 | 25 | 135 |

906# | 206.38 | 152.4 | 133.35 | 3560 | 907# | 165.1 | 111.76 | 104.78 | 1560 |

910# | 50.8 | 50.8 | 6 | 8 | 916# | 150 | 65 | 19 | 140 |

918# | 250 | 200 | 100 | 4300 | 919# | 200 | 150 | 100 | 2500 |

920# | 170 | 170 | 100 | 2400 | 921# | 190 | 190 | 100 | 3000 |

959# | 300 | 220 | 70 | 3950 | 966# | 160 | 47 | 23.5 | 115 |

978# | 65 | 30 | 17 | 21 | 989# | 50 | 12 | 9 | 2.5 |

990# | 70 | 14 | 10 | 5 | 992# | 62 | 22 | 16 | 15 |

A20# | 83 | 12.7/11.7 | 4.5 | 5 | 805# | 13 | 13 | 8 | 0.6 |

A39# | 18 | 100 | 10 | 9 | A51# | 190 | 190 | 50 | 1460 |

A52# | 65 | 65 | 30 | 90 | A59# | 100 | 45 | 19 | 60 |

A92# | 95 | 48 | 74 | 215 | A93# | 107 | 60 | 69 | 330 |

A94# | 150 | 80 | 55 | 450 | A95# | 250 | 200 | 120 | 5240 |

B18# | 220 | 45 | 50 | 330 | B19# | 54 | 38 | 20 | 25 |

B23# | 40 | 30 | 6 | 5 | B34# | 15 | 8 | 100 | 5.5 |

B71# | 40 | 100 | 20 |

| B72# | 58 | 145 | 29 |

|

B90# | 125 | 125 | 85 |

| B96# | 105 | 22 | 14.5 |

|

B99# | 70 | 70 | 30 |

| C07# | 125 | 60 | 20 |

|

C09# | 137 | 27 | 21 |

| C34# | 250 | 250 | 50 |

|

C75# | 140 | 140 | 60 |

| C81# | 100 | 14 | 12 |

|

C84# | 150 | 150 | 95 |

| C88# | 75 | 50 | 11 |

|

D12# | 50 | 12 | 10 |

| D13# | 75 | 15 | 10 |

|

D14# | 90 | 17 | 11.5 |

| 801# | 55/45 | 13 | 9/2 |

|

D37# | 205 | 100 | 300 |

| D54# | 120 | 30 | 15 |

RFQ

1. What information should we supply to get a quote?

Please offer the specification of alumina ceramic crucible, such as shape, dimension, quantity, application etc.

2. What types of materials can be melted in a alumina crucible boats?

alumina crucible boats are suitable for melting a wide range of materials, including metals, alloys, and glass. They are commonly used in the metallurgical, chemical, and glass industries for melting and processing various materials.

3. How do I properly handle a hot alumina crucible boats?

When handling a hot alumina crucible boats, always wear heat-resistant gloves or use tongs to avoid direct contact with the crucible. Allow the crucible to cool down completely before attempting to remove it from the furnace or handling it with bare hands.

4. How durable is a alumina crucible boats?

A alumina crucible boats is highly durable and has excellent thermal shock resistance, making it ideal for use in high-temperature applications.

Quality testing standards

1. Visual inspection of the crucible for any signs of damage or irregularities.

2. Measurement of the length, width, and thickness of the crucible to check for accuracy.

3. Checking for any leaks or pinhole defects in the crucible.

4. Verification of the material and chemical composition of the crucible.

Package