Alumina Crucible

- yunxing

- china

- According to the quantity ordered

- 2000-5000/month(Looking for distributors)

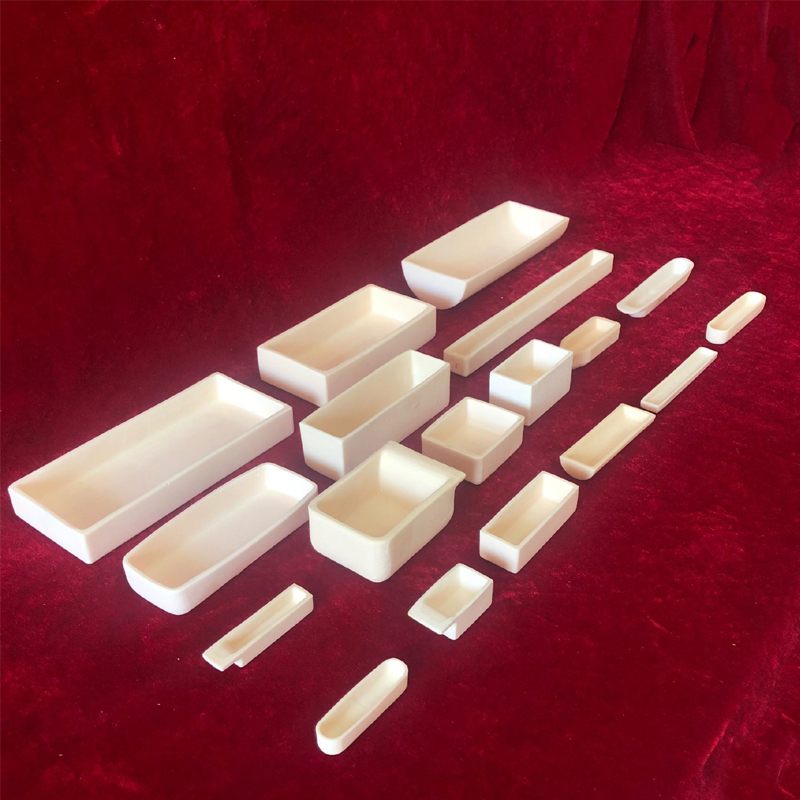

Alumina crucible. The shape is mainly cylindrical, conical, square, etc. The alumina crucible has a high purity, containing over 99% AL2O3. 99% alumina material is used to make high-temperature crucibles, with good chemical corrosion resistance and temperature resistance. Alumina crucible can be used for a long time at 1650 ℃, and can also be used at temperatures up to 1800 ℃. But it can only be used for a short period of time.

Alumina Crucible

Description of alumina crucible

Alumina crucible. The shape is mainly cylindrical, conical, square, etc. The alumina crucible has a high purity, containing over 99% AL2O3. 99% alumina material is used to make high-temperature crucibles, with good chemical corrosion resistance and temperature resistance. Alumina crucible can be used for a long time at 1650 ℃, and can also be used at temperatures up to 1800 ℃. But it can only be used for a short period of time.

Application of alumina crucible

Aluminum oxide crucibles are used for analyzing and melting various laboratory metal and non-metal samples, as well as firing pigments, colorants, glass materials, pigments, luminescent materials, etc. in shuttle kilns and push plate kilns. Aluminum oxide crucibles are used in small experimental kilns, experimental electric furnaces for adjusting formulas, and other purposes. Melting metals, precious metals, optical glasses, used for analyzing and firing mineral raw materials such as rare earths, as well as firing high-temperature products such as ceramic powders.

Advantages of alumina crucibles

1. Alumina crucible has good resistance to sudden heat and cold, and is not easy to explode.

2.The alumina crucible is formed by slip casting molding, so its density is high.

3.In oxidizing and reducing atmospheres, alumina crucibles have good high-temperature insulation and mechanical strength.

4.Alumina crucibles have high thermal conductivity and low thermal expansion rate.

FAQ

1.What is alumina crucible?

Crucibles are used in chemistry laboratories as containers for extremely hot chemical compounds and are made from materials with high-temperature resistance. The ceramic form of alumina is commonly used because of its low cost, strength, and ability to withstand temperatures as high as 3272°F (1800°C).

2.Is alumina crucible better than graphite?

Alumina crucibles have longer life span compared to clay graphite crucibles, and provide advantage especially for continuous working systems.

3.Can alumina crucibles be customized?

Yes.We accept customized alumina crucibles based on drawings.

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.