Alumina Ceramic Parts

-

Alumina parts

1.Alumina parts is their exceptional strength and durability. Making them ideal for industries that demand strength and toughness.

Email Details

2.Alumina parts excellent resistance to wear. Allowing them to withstand repetitive friction, corrosion, and heat without compromising their structural integrity.

3.Alumina parts is their outstanding thermal conductivity. The ability to efficiently conduct heat enables these parts to withstand high temperatures without distortion or degradation.

4.By choosing alumina parts, customers can expect increased operational lifespan, reduced downtime, improved energy efficiency, and enhanced overall productivity. -

99.3% Alumina Ceramic Parts Custom

1. Unmatched durability and strength: Alumina Ceramic Parts Custom can withstand heavy loads without cracking or deformation.

Email Details

2. Efficient heat transfer: Alumina Ceramic Parts Custom is conducive to uniform heat distribution, reducing energy consumption, and improving the efficiency of the entire system.

3. Reliability and lifespan: Alumina Ceramic Parts Custom high-temperature resistance ensures stability even under extreme operating conditions, minimizing the risk of failure and expensive downtime.

4.Wide range of sizes and customization options: Whether it's specific lengths, diameters, or any other customization, we are committed to meeting your expectations. -

Wear-Resisting Alumina Ceramic Flanges Parts

1.One of the prominent features of wear-resisting alumina ceramic flanges parts is their excellent strength and durability.

Email Details

2.Another major advantage of wear-resisting alumina ceramic flanges parts is their excellent thermal conductivity.

3.Wear-resisting alumina ceramic flanges parts have unparalleled versatility and adaptability, suitable for various industries and applications. -

Hot

Alumina Precision Parts

▪ Alumina precision parts made by 99.3%-99.7% high purity alumina

Email Details

▪ Alumina precision parts have excellent mechanical strength, electrical insulation, and corrosion resistance

▪ Alumina precision parts max working temperature is 1800C

▪ The quality can pass the SGS and DIN43724/DIN43725/DIN40680

▪ Alumina precision parts can accept the custom shape and size without MOQ -

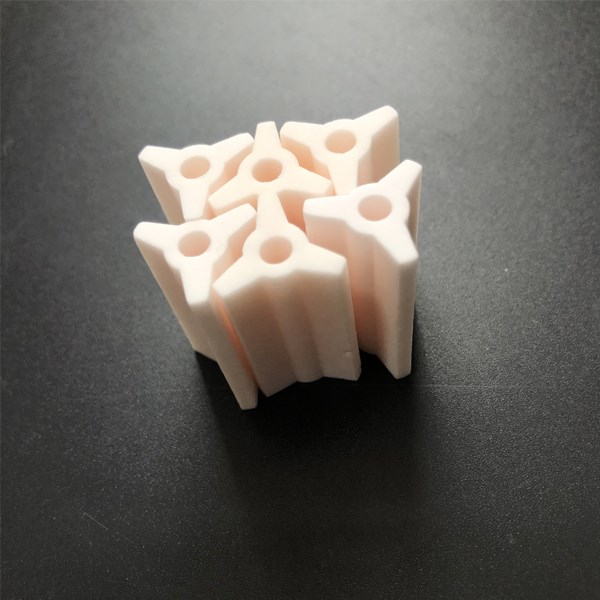

Alumina Ceramic Screw Parts

1. Alumina ceramic screw part have high corrosion resistance and are very suitable for use in harsh environments.

Email Details

2. Alumina ceramic screw part can withstand high temperatures without losing their integrity, and can be used for extreme high temperature applications in a short period of time.

3. Alumina ceramic screw part have excellent wear resistance and are suitable for use in severely worn environments. -

Alumina Ceramic Nut Parts

1.This is the alumina ceramic nut parts, it is soild screw bar, the screw size is M2. We also accept the custom size and shape about this parts.

Email Details

2.Compared with common metal parts, alumina ceramic nut parts have higher hardness and strength, better wear resistance, better stability, excellent biocompatibility, etc.

3.Alumina ceramic nut parts have the characteristics of high temperature resistance, corrosion resistance, rapid cooling and rapid heat, high mechanical strength and superior electrical performance.

4.Alumina ceramic nut parts are widely used in industrial equipment manufacturing and other fields. -

Supply Alumina Ceramic Element Parts

1.High Temperature Resistance: Alumina Ceramic Element Parts can withstand high temperatures, making them suitable for applications in environments with extreme heat.

Email Details

2.Mechanical Strength: Alumina Ceramic Element Parts have excellent mechanical properties, including high hardness and stiffness, which make them durable and resistant to wear and abrasion.

3.Chemical Resistance: Alumina Ceramic Element Parts are highly resistant to many chemicals, acids, and alkalis, making them suitable for use in corrosive environments. -

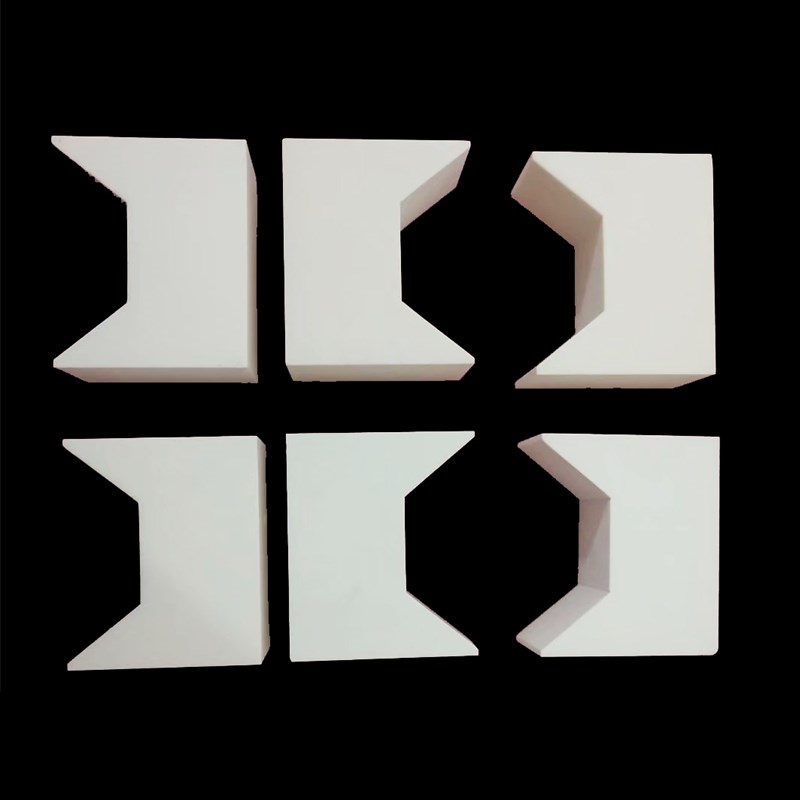

Alumina Ceramic Fasteners/Industrial Fasteners

Alumina Ceramics are the most highly regarded and widely used of the ceramic products.

Email Details

It is non-conductive, resistant to corrosion, and are perfect for electrical insulation. Alumina Ceramic has proven to be the best ceramic for protection of vital electrical components.

It can be processed as tubing, sheets, bars, rods, discs, and many other forms depending on the requirements of the project. -

Precision Drilling Alumina Ceramic Parts

One of the most common characteristics of industrial ceramics parts is its extremely high hardness and rigidity, some of which are more than 4 times that of stainless steel. Such high hardness directly translates into excellent wear resistance, which means that they can have the ability to maintain accurate and high tolerance surface treatment for a longer period of time than any other material.

Email Details