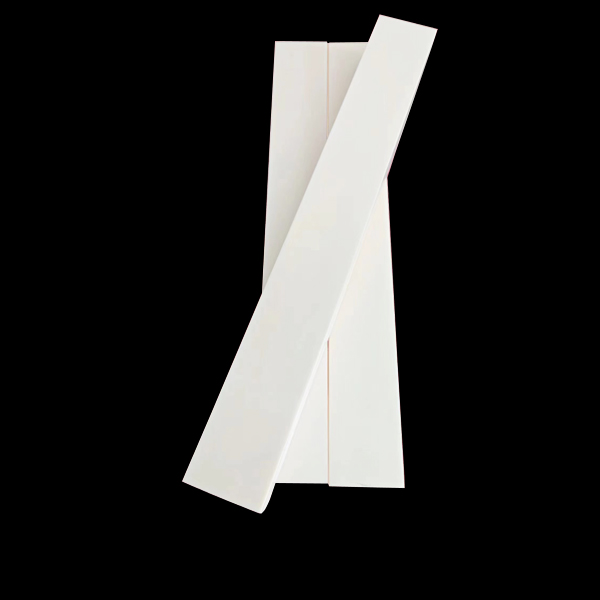

Alumina Corundum Tube Square

- YUNXING

- China Jinzhou

- 5-30 Days

- 5,000-10,000/month(Looking for distributors)

1. High temperature resistance:

One of the most significant features of alumina corundum tubes square is their unparalleled high-temperature resistance, which makes them very suitable for applications involving heat treatment.

2. Excellent thermal conductivity:

Alumina corundum tubes square have excellent thermal conductivity, which facilitates effective heat transfer in various systems.

3. Excellent corrosion resistance:

Corrosion resistance is another key advantage of alumina corundum tubes square . Their non reactivity and inertness make them resistant to chemical corrosion even in harsh environments.

4. Excellent mechanical strength:

Although the composition of alumina corundum tubes square is ceramic, they exhibit extraordinary mechanical strength and durability. Its sturdy characteristics enable it to withstand mechanical stresses such as pressure and impact without deformation or failure.

Alumina Corundum Tube Square

My factory looking for distributors.

Advantages of Alumina Corundum Tube Square

1. High temperature resistance:

One of the most significant features of alumina corundum tubes square is their unparalleled high-temperature resistance, which makes them very suitable for applications involving heat treatment.

2. Excellent thermal conductivity:

Alumina corundum tubes square have excellent thermal conductivity, which facilitates effective heat transfer in various systems.

3. Excellent corrosion resistance:

Corrosion resistance is another key advantage of alumina corundum tubes square . Their non reactivity and inertness make them resistant to chemical corrosion even in harsh environments.

4. Excellent mechanical strength:

Although the composition of alumina corundum tubes square is ceramic, they exhibit extraordinary mechanical strength and durability. Its sturdy characteristics enable it to withstand mechanical stresses such as pressure and impact without deformation or failure.

5. Dimensional stability:

Alumina corundum tubes square exhibit excellent dimensional stability under various operating conditions.

6. Electrical insulation performance:

Another significant advantage of alumina corundum tubes square is their excellent electrical insulation performance. As electrical insulation materials, these tubes prevent current flow, making them suitable for applications that require electrical isolation or insulation.

7. Multifunctional applications:

The versatility of alumina corundum tubes square enables their use in different industries and applications.

Application of Alumina Corundum Tube Square

A. In furnaces, kilns, and other high-temperature environments, alumina corundum tube squares serve as reliable conduits for heat transfer, ensuring efficient operation and prolonged equipment lifespan.

B. Alumina corundum tube squares resistance to corrosion and chemical degradation further enhances their suitability for demanding environments where exposure to corrosive substances is prevalent.

C.Alumina corundum tube squares play a pivotal role in the fabrication of insulating components and high-performance circuitry.

D.Alumina corundum tube squares ensures minimal contamination risk in sensitive environments such as semiconductor manufacturing and pharmaceutical production.

E.Alumina corundum tube squares find utility in scientific research, From chromatography columns to sample containment vessels, these components contribute to the advancement of scientific knowledge by providing a dependable platform for experimentation and analysis.

Tube size: 30*40*400mm

The Performance of Alumina Corundum Tube

1. Alumina corundum tubes have a high density, greatly reducing the secondary oxidation of molten steel during the pouring process and reducing the entry of inclusions into the casting model.

2. Alumina corundum pipes have high fire resistance (>1680 * C), corrosion resistance, smooth surface of the flow channel after pouring, and no corrosion during the pouring process. Good chemical stability, no chemical reaction with the molten metal (iron or steel) of the casting at high temperatures.

3. The high thermal strength and good thermoplastic properties of alumina corundum tubes can effectively prevent sand flushing and sand inclusion in castings, and reduce sand hole defects in castings.

4. The thermal expansion coefficient of alumina corundum tube is low and has almost no effect on the shrinkage of the casting. Reduced the phenomenon of tensile cracking caused by the pouring system.

5. The surface of alumina corundum tube is delicate and smooth, with low flow resistance and fast flow rate. The present invention can effectively reduce thermal cracks caused by thermal stress in castings due to various resistances caused by the gating system, mold, sand core, and casting structure.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Our Factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

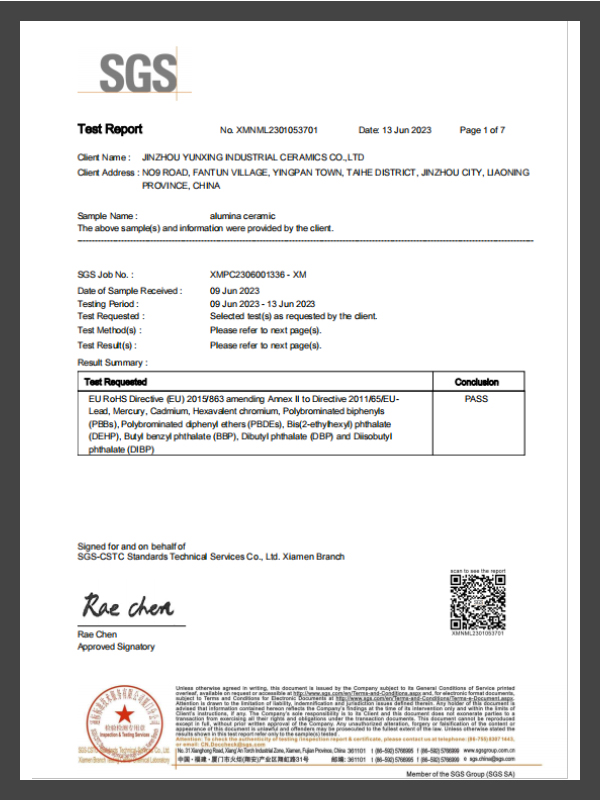

Certification

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.