Alumina Ceramic Thermocouple Tube

- YUNXING

- China Jinzhou

- 5-30 Days

- 5,000-10,000/month(Looking for distributors)

Alumina ceramics have:

A. Good mechanical strength, electrical conductivity and high temperature resistance.

B. Because it is very superior in performance, it is more and more widely used in the current market.

C. It can not only effectively meet daily use, but also meet some special needs.

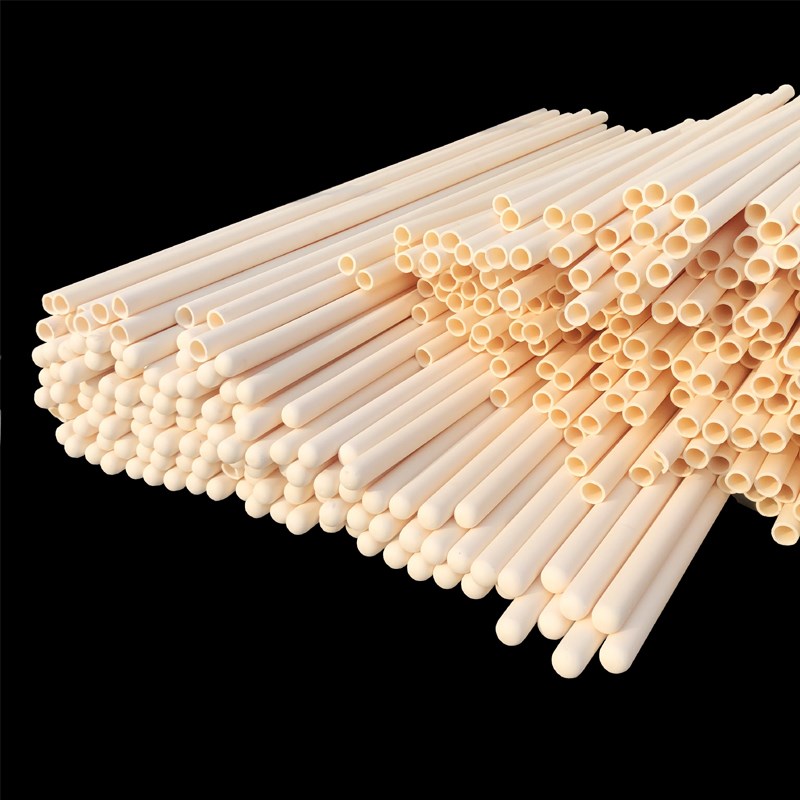

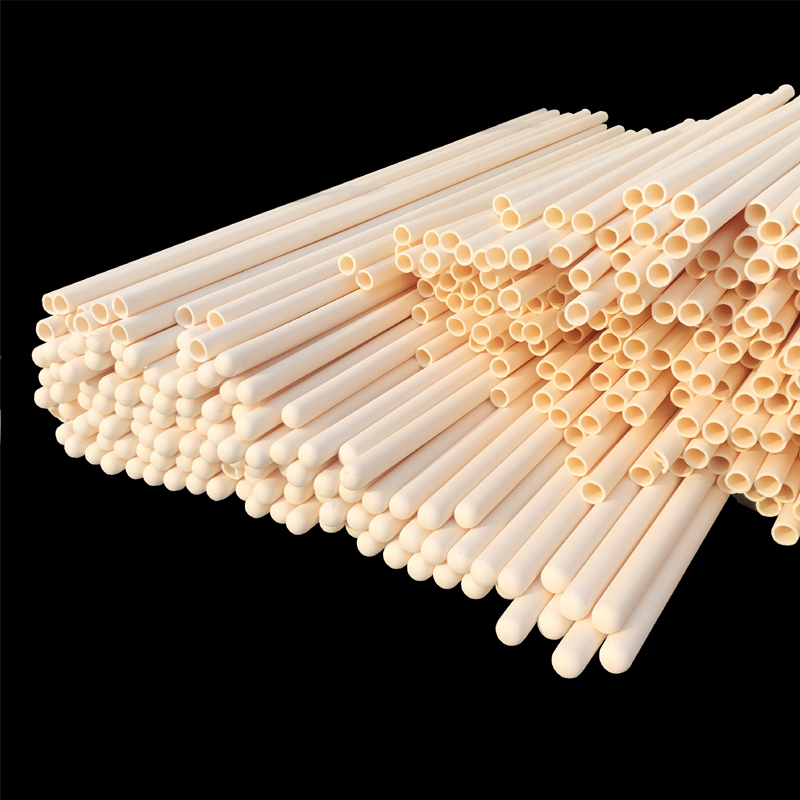

Alumina Ceramics Thermocouple tube

My factory looking for distributors.

Alumina ceramics have good mechanical strength, conductivity and high temperature resistance. In fact, alumina ceramics are the most widely used ceramics. Because it is very superior in performance, it is more and more widely used in the current market. It can not only effectively meet the daily use, but also meet some special needs.

Alumina ceramics are also divided into different types. Among them, 99.7% alumina ceramics are made of high-purity alumina materials, coupled with a series of related strict process guarantees, and the performance is more superior. Compared with 99% alumina and 95% oxidation Aluminum has higher density and higher bending strength.

Recommended products

Ceramic tray:

Corrosion resistance, high fire resistance and good chemical stability. Used in laboratory extraction, burning, mineral, chemical and other industries.

Ceramic rods:

With high density&refractoriness,good corrosion resistence,mechanical capacity etc properties,ceramic rods are widely used in chemical fiber,textile and chemical etc industries.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Composition table

| NAME | CONTENT(%) |

| Al2O3 | 99.3-99.5(99.7) |

| SiO2 | 0.3-0.5 |

| CaO+MgO | 0.2-0.3 |

| K2O+Na2O | 0.2-0.35 |

| Fe2O3 | <0.1 |

| OTHER | <0.05 |

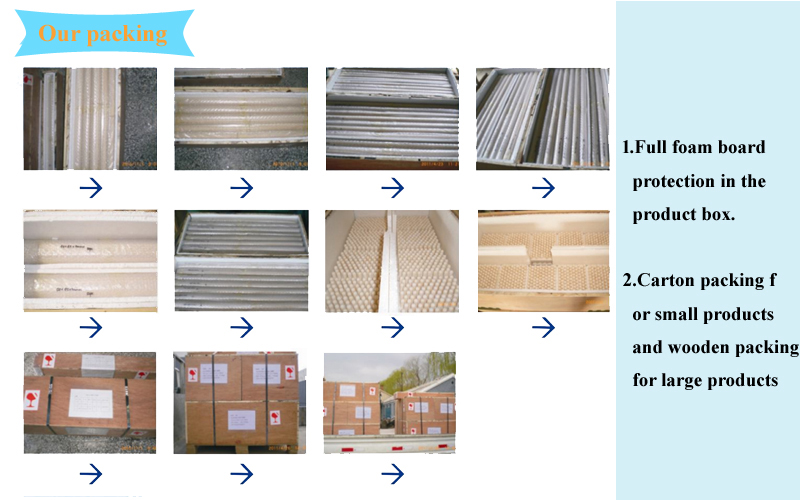

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

Alumina purity test report

RFQ

1.What are the benefits of alumina ceramics?

Alumina ceramics is a widely used material because it can be produced in a range of purities—from 85 to 99.9 percent pure—that provide unique benefits. Generally, alumina ceramic components offer quality strength, hardness, corrosion resistance, and thermal stability.

2.What is the temperature rating of alumina ceramic?

Alumina is often used as a replacement for metallic components in demanding engineering applications. IPS Ceramics supply 95% alumina for applications below 1450 ºC / 2650 °F and 99% alumina for temperatures up to 1600 ºC / 2900 °F or where contamination of the sample must be avoided.

3.What is the disadvantage of alumina?

Alumina shares several characteristics with other polycrystalline ceramic materials, such as moderate tensile and bending resistance and the brittle fracture behavior, which is the main disadvantage of the mechanical properties of alumina.

Feedback