99.3% Alumina Ceramic Parts Custom

- yunxing

- china

- According to the quantity ordered

- 3000-6000/month(Looking for distributors)

1. Unmatched durability and strength: Alumina Ceramic Parts Custom can withstand heavy loads without cracking or deformation.

2. Efficient heat transfer: Alumina Ceramic Parts Custom is conducive to uniform heat distribution, reducing energy consumption, and improving the efficiency of the entire system.

3. Reliability and lifespan: Alumina Ceramic Parts Custom high-temperature resistance ensures stability even under extreme operating conditions, minimizing the risk of failure and expensive downtime.

4.Wide range of sizes and customization options: Whether it's specific lengths, diameters, or any other customization, we are committed to meeting your expectations.

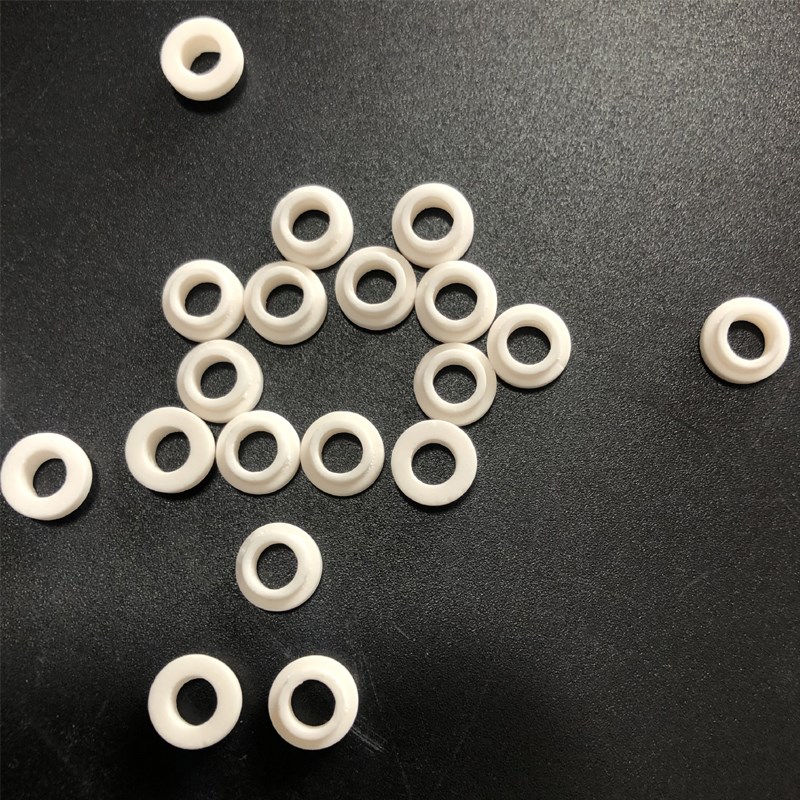

99.3% Alumina Ceramic Parts Custom

My factory looking for distributors.

All products through the German DIN standards: DIN43724 / DIN43725 / DIN40680

Advantages of Alumina Ceramic Parts Custom

1. Unmatched durability and strength: Alumina Ceramic Parts Custom can withstand heavy loads without cracking or deformation.

2. Efficient heat transfer: Alumina Ceramic Parts Custom is conducive to uniform heat distribution, reducing energy consumption, and improving the efficiency of the entire system.

3. Reliability and lifespan: Alumina Ceramic Parts Custom high-temperature resistance ensures stability even under extreme operating conditions, minimizing the risk of failure and expensive downtime.

4.Wide range of sizes and customization options: Whether it's specific lengths, diameters, or any other customization, we are committed to meeting your expectations.

1. Alumina Ceramic Parts Custom : generally used for positioning, not easy to fall off, and sliding purposes.

2.Alumina Ceramic Parts Custom mainly serves a protective role, protecting the shaft and substrate from direct wear.

Composition table

| NAME | CONTENT(%) |

| Al2O3 | 99.3-99.5(99.7) |

| SiO2 | 0.3-0.5 |

| CaO+MgO | 0.2-0.3 |

| K2O+Na2O | 0.2-0.35 |

| Fe2O3 | <0.1 |

| OTHER | <0.05 |

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | - |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Cold compressive strength | MPa | 350 |

6 | 20ºC leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600ºC |

8 | Bonding in high temperature | not bonded in 1600ºC | |

9 | 20-1000ºC coefficient ofthermalexpansion | mm.10-6/ºC.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20ºCdirect current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000ºC MΩ | ≥0.08 |

1300ºC MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550ºC | |

15 | Maximum working temperature | ºC | 1800 |

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

FAQ

What is the difference between ceramic and alumina?

Ceramics are non-metallic, inorganic materials that are typically composed of a combination of metallic and non-metallic elements. Alumina is a type of ceramic oxide, specifically an oxide of aluminum. It is widely used in various applications due to its excellent mechanical, thermal, and electrical properties.

What is alumina ceramic used for?

Everything You Need to Know about Alumina Ceramics

Because of their excellent chemical stability, alumina ceramics are used widely in acid-resistant pump impellers, pump bodies, acid-carrying pipe linings and valves. Aluminum oxide ceramics are used in the manufacture of textile wear parts and knives. This is due to their extreme hardness and wear resistance.

Is alumina ceramic hard?

Alumina is a very hard ceramic that is excellent at resisting abrasion and is ideal for wear-resistant inserts or products.

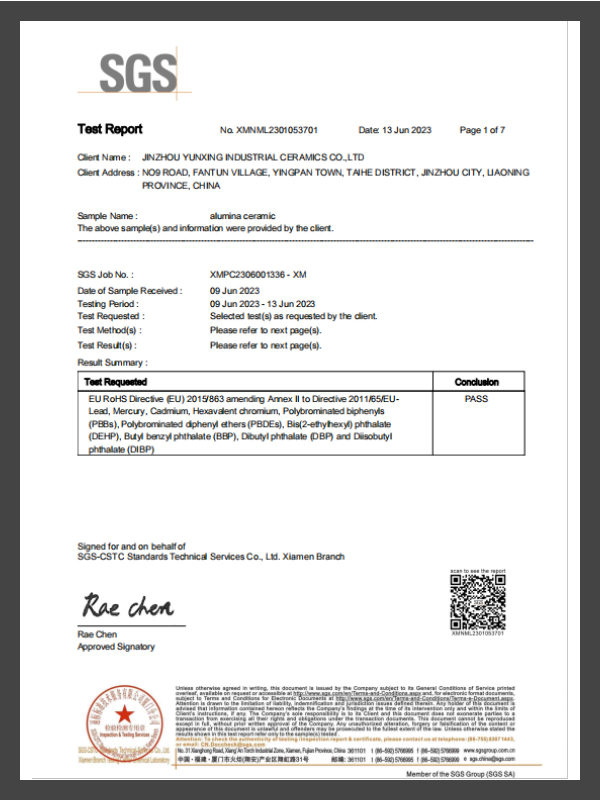

Certification

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.