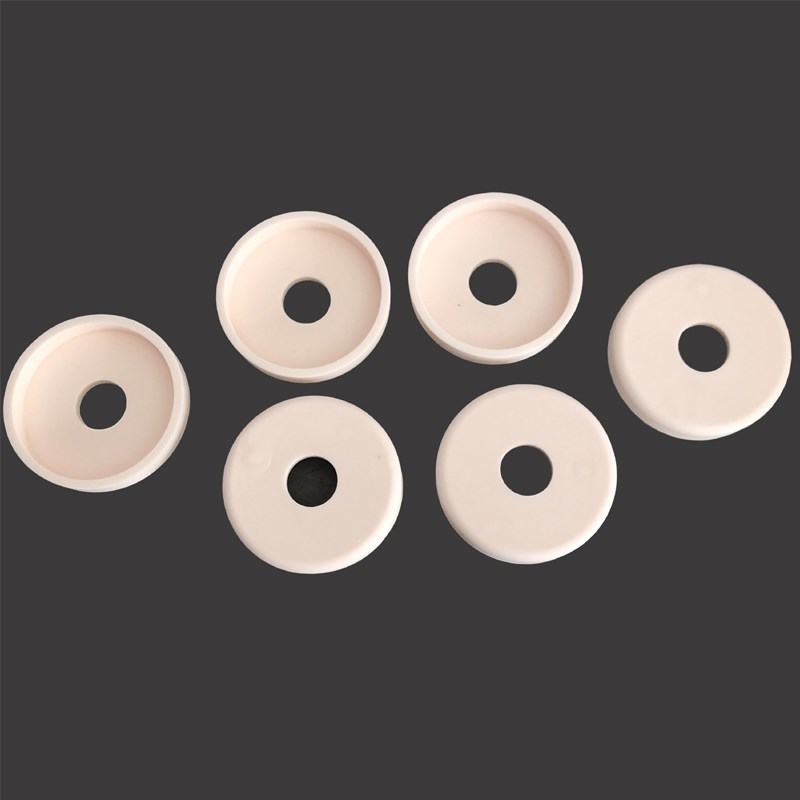

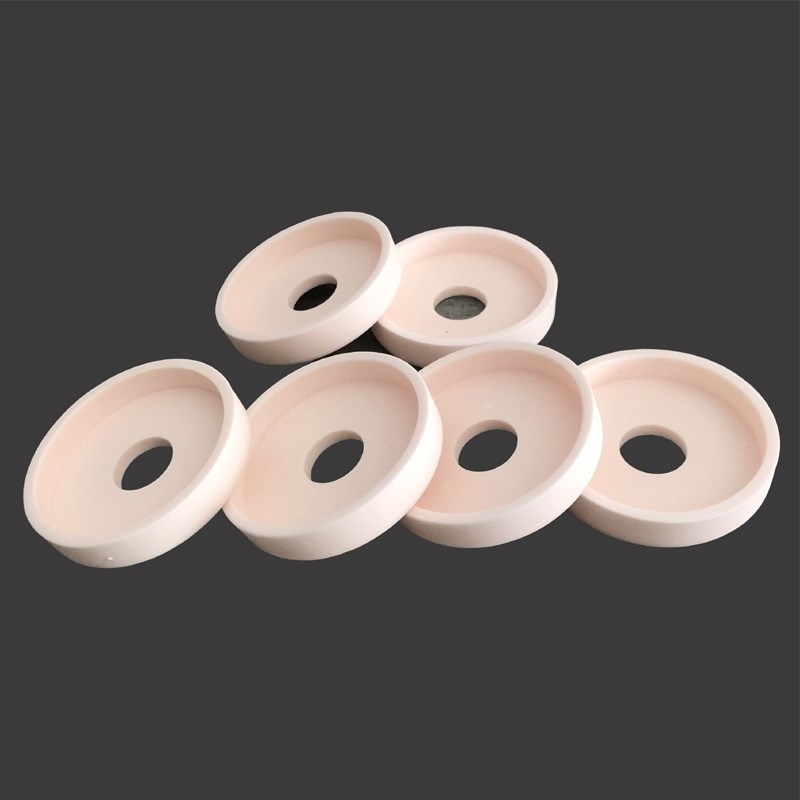

Industrial Alumina Ceramic Crucible Cover

- yunxing

- china

- According to the quantity ordered

- 3000-6000/month(Looking for distributors)

A. The alumina ceramic crucible lid is mainly made of alumina.

B. Can withstand high temperature of 1800 degrees Celsius, high temperature resistance.

C. Has excellent chemical resistance and high temperature resistance.

Industrial Alumina Ceramic Crucible Cover

My factory looking for distributors.

Alumina Ceramic Crucible Cover is mainly made of alumina. It is fired at high temperature with a special formula. It is a refractory with high fire resistance. It can withstand temperatures of 1800 degrees Celsius and high temperature resistance. It is usually used for smelting precious metals, nickel And other metals, with excellent chemical resistance and high temperature resistance.

All products through the German DIN standards: DIN43724 / DIN43725 / DIN40680

When the crucible is in use, the lid is usually placed on the crucible at an Angle to prevent the heated matter from jumping out and to allow air to flow in and out freely for possible oxidation reactions.

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 |

| >99.3 |

2 | SiO2 |

| — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption |

| 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 |

20—1000℃ coefficient of thermal expansion |

mm.10-6 /℃.m |

8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 |

20℃direct current insulation resistance |

Ohm/cm |

1014 |

13 |

High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

Alumina purity test report

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: Alumina ceramic

3. Lead time: pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T;

7. Shipment: by sea, by air, by courier, by post, etc.

8.What is the maximum temperature for alumina crucible?

The temperature range of alumina crucibles is typically between 1600°C to 1800°C.

9.Why alumina crucible is used?

Alumina Crucible Applications

Used as a material for industrial furnaces due to its ability to maintain its hardness at high temperatures. Used as a protector for high- temperature thermal couples. Used as a material for the chemical industry due to its high corrosion resistance.

10.What is the advantage of using crucible and cover?

The benefits of crucible lie in its ability to withstand very high temperatures, which makes it ideal for laboratory experiments involving extremely hot chemical reactions as well as corrosive and pigmentation processes. It is a common chemistry lab apparatus that is used for heat-related experiments.

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.