High Purity Alumina Tube

- YUNXING

- China Jinzhou

- 5-30 Days

- 5,000 -10,000 / month(Looking for distributors)

1. High purity alumina tubes have good stability:

The surface of alumina tube has flame retardancy and good fire resistance, and its working performance will not be affected at a high temperature of 1200 degrees. Alumina tubes are the nemesis of all acidic, alkaline, and other chemical substances, whether they are chemical solvents, corrosive agents, or other chemical dyes, they will not affect the surface of ceramic tubes.

2. High purity alumina tubes are easy to clean:

The surface of alumina tubes has strong corrosion resistance and can be easily cleaned with detergent without affecting their color and surface; And the surface is tightly impermeable and not easy to adhere dust.

3. High purity alumina tube anti-static:

High purity alumina tubes are made of aluminum oxide material and have been proven to be anti-static materials, unless a certain degree of low conductivity is achieved.

High Purity Alumina Tube

Advantages of High Purity Alumina Tube

1. High purity alumina tubes have good stability:

The surface of alumina tube has flame retardancy and good fire resistance, and its working performance will not be affected at a high temperature of 1200 degrees. Alumina tubes are the nemesis of all acidic, alkaline, and other chemical substances, whether they are chemical solvents, corrosive agents, or other chemical dyes, they will not affect the surface of ceramic tubes.

The surface of alumina tubes has strong corrosion resistance and can be easily cleaned with detergent without affecting their color and surface; And the surface is tightly impermeable and not easy to adhere dust.

High purity alumina tubes are made of aluminum oxide material and have been proven to be anti-static materials, unless a certain degree of low conductivity is achieved.

The surface structure of alumina tubes is finely processed and is not easily damaged by external hard objects. Ceramic tubes have strong impact resistance.

Application of High purity alumina tubes

1.Because of their excellent chemical stability, High purity alumina tubes are used widely in acid-resistant pump impellers, pump bodies, acid-carrying pipe linings and valves.

2.High purity alumina tubes are used in the manufacture of textile wear parts and knives. This is due to their extreme hardness and wear resistance.

3.High purity alumina tubes is the most commonly used abrasive grain in the woodwork and metalwork industry. This is because it does a better job than silicon carbide on several materials, including bare wood, painted surfaces, and metal.

4.High purity alumina tubes materials are used in making spark plugs, which are useful in a wide variety of engines.

5.Transparent high purity alumina tubes are used in making high-pressure sodium lamps and infrared detection window material.

6.With an alumina content higher than 95%, alumina ceramics can be used as excellent electrical insulators. They also have a low dielectric loss, with a wide range of applications in electronics and electrical appliances.

Instructions for use

1. When using alumina tubes, it is best to control the heating and cooling rate to 5 degrees / minute, the slower the better.

2. Rapid cooling and rapid heating are one of the main reasons for the rupture of the alumina tube. Our products have good resistance to quenching and heating.

3. Please keep the alumina tube clean at all times, do not leave some samples in the alumina tube, one side chemical reaction and cracking of the alumina tube. It is recommended to put the test sample into the crucible and alumina tube.

4. During lofting and sampling, it is best to be within 200 degrees and slowly push from the edge to the middle. High temperature sample delivery and sampling is also the main reason for corundum tube rupture.

5. Make sure to place mullite plugs on both sides of the aluminatube to prevent heat radiation from damaging the silicone ring in the flange. The crucible should be placed in the middle of the alumina tube.

Alumina Tube(open both ends)(slip casting) Specification Table

Number | SPEC: OD x ID |

LENGTH MM |

Number | SPEC: OD x ID |

LENGTH MM | ||

INCH | MM | INCH | MM | ||||

1 | 0.197x0.118 | 5x3 | ≤800 | 32 | 1.126x0.886 | 28.6x22.5 |

≤1800 |

2 | 0.236x0.157 | 6x4 |

≤1300 | 33 | 1.181x0.827 | 30x21 | |

3 | 0.250x0.125 | 6.4x3.2 | 34 | 1.181x0.906 | 30x23 | ||

4 | 0.250x0.157 | 6.4x4 | 35 | 1.260x0.984 | 32x25 | ||

5 | 0.250x0.188 | 6.4x4.8 | 36 | 1.375x1.125 | 34.9x28.6 | ||

6 | 0.276x0.157 | 7x4 | 37 | 1.378x1.063 | 35x27 | ||

7 | 0.276x0.197 | 7x5 | 38 | 1.496x1.181 | 38x30 | ||

8 | 0.315x0.197 | 8x5 | 39 | 1.575x1.181 | 40x30 | ||

9 | 0.354x0.236 | 9x6 |

≤1600 | 40 | 1.654x1.339 | 42x34 | |

10 | 0.375x0.250 | 9.6x6.4 | 41 | 1.750x1.500 | 44.5x38.1 | ||

11 | 0.394x0.236 | 10x6 | 42 | 1.811x1.496 | 46x38 | ||

12 | 0.394x0.276 | 10x7 | 43 | 1.875x1.625 | 47.6x41.3 | ||

13 | 0.433x0.276 | 11x7 | 44 | 1.969x1.575 | 50x40 | ||

14 | 0.472x0.236 | 12x6 | 45 | 2.000x1.750 | 50.8x44.5 | ||

15 | 0.472x0.315 | 12x8 | 46 | 2.250x2.000 | 57.2x50.8 | ||

16 | 0.472x0.355 | 12x9 | 47 | 2.283x1.890 | 58x48 | ||

17 | 0.500x0.250 | 12.7x6.4 | 48 | 2.362x1.96 | 60x50 | ||

18 | 0.500x0.375 | 12.7x9.5 | 49 | 2.500x2.250 | 63.5x57.2 | ||

19 | 0.551x0.394 | 14x10 | 50 | 2.559x2.165 | 65x55 | ||

20 | 0.591x0.394 | 15x10 |

≤1800 | 51 | 2.750x2.500 | 69.9x63.5 | |

21 | 0.630x0.472 | 16x12 | 52 | 2.756x2.362 | 70x60 | ||

22 | 0.669x0.472 | 17x12 | 53 | 2.956x2.561 | 75x65 | ||

23 | 0.688x0.437 | 17.5x11.1 | 54 | 3.000x2.750 | 76x70 | ||

24 | 0.750x0.512 | 19.1x13 | 55 | 3.150x2.675 | 80x68 | ||

25 | 0.787x0.591 | 20x15 | 56 | 3.500x3.125 | 88.9x79.4 |

≤1600 | |

26 | 0.866x0.630 | 22x16 | 57 | 3.543x3.150 | 90x80 | ||

27 | 0.866x0.669 | 22x17 | 58 | 3.937x3.543 | 100x90 | ||

28 | 0.945x0.709 | 24x18 | 59 | 4.000x3.650 | 101.6x93 | ||

29 | 1.000x0.750 | 25.4x19.1 | 60 | 4.331x3.937 | 110x100 |

≤1500 | |

30 | 1.063x0.669 | 27x17 | 61 | 4.500x4.125 | 114.3x105 | ||

31 | 1.063x0.787 | 27x20 | 62 | 4.724x4.331 | 120x110 | ||

Insulation tube (extrusion) Specification Table

Number | 1 Bore tube SPEC: OD x ID | LENGTH MM | |

INCH | MM | ||

1 | 0.031x0.011 | 0.8x0.3 |

≤18500 |

2 | 0.039x0.019 | 1x0.5 | |

3 | 0.059x0.024 | 1.5x0.6 | |

4 | 0.079x0.039 | 2x1 | |

5 | 0.100x0.050 | 2.5x1.3 | |

6 | 0.118x0.059 | 3x1.5 | |

7 | 0.118x0.079 | 3x2 | |

8 | 0.125x0.063 | 3.2x1.6 | |

9 | 0.157x0.079 | 4x2 | |

10 | 0.197x0.118 | 5x3 | |

11 | 0.236x0.118 | 6x3 | |

12 | 0.236x0.157 | 6x4 | |

13 | 0.250x0.125 | 6.4x3.2 | |

14 | 0.250x0.157 | 6.4x4 | |

15 | 0.250x0.188 | 6.4x4.8 | |

16 | 0.276x0.197 | 7x5 | |

17 | 0.315x0.197 | 8x5 | |

18 | 0.354x0.236 | 9x6 | |

19 | 0.374x0.250 | 9.5x6.35 | |

20 | 0.394x0.236 | 10x6 | |

21 | 0.433x0.276 | 11x7 | |

22 | 0.472x0.315 | 12x8 | |

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | - |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Cold compressive strength | MPa | 350 |

6 | 20ºC leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600ºC |

8 | Bonding in high temperature | not bonded in 1600ºC | |

9 | 20-1000ºC coefficient ofthermalexpansion | mm.10-6/ºC.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20ºCdirect current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000ºC MΩ | ≥0.08 |

1300ºC MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550ºC | |

15 | Maximum working temperature | ºC | 1800 |

Composition table

| NAME | CONTENT(%) |

| Al2O3 | 99.3-99.5(99.7) |

| SiO2 | 0.3-0.5 |

| CaO+MgO | 0.2-0.3 |

| K2O+Na2O | 0.2-0.35 |

| Fe2O3 | <0.1 |

| OTHER | <0.05 |

Our Factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

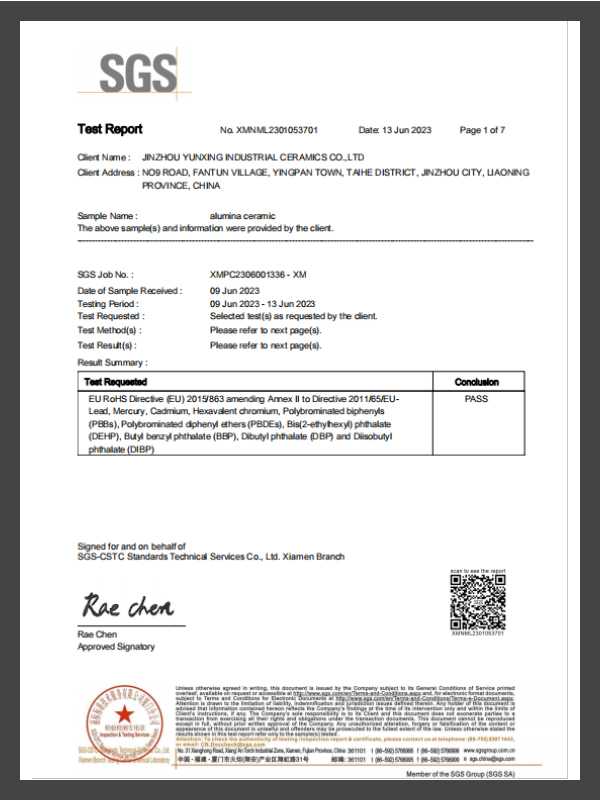

Certificate

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.