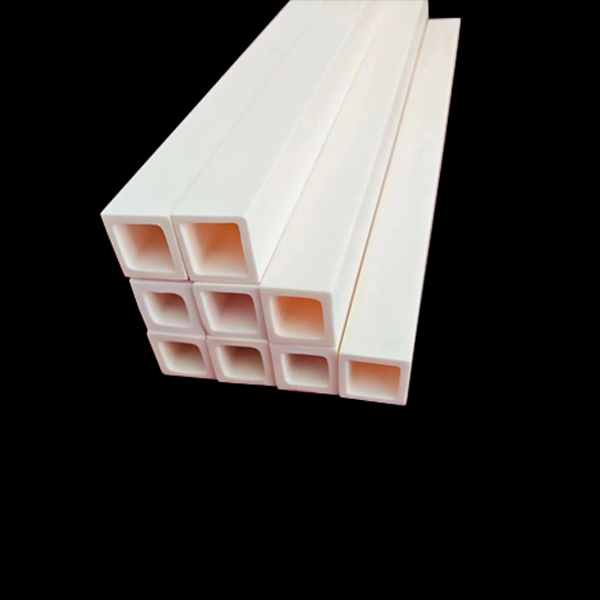

Industrial Ceramic Pipes

- Yunxing

- China

- Depending on product size and quantity

- 3000-5000/month

Industrial ceramic pipes, also known as alumina ceramic tube, is made of alumina (Al2O3) material.

1. Industrial ceramic pipes are made of advanced alumina and have excellent heat and chemical resistance.

2.The design of industrial ceramic pipes has excellent heat transfer performance.

3. Industrial ceramic pipes are customizable and easy to install, making them an excellent choice for various engineering applications.

4. The design of industrial ceramic pipes has durability and long-term usability, ensuring that you get the maximum return from your investment.

Industrial Ceramic Pipes

Advantages of industrial ceramic pipes

Industrial ceramic pipes, also known as alumina ceramic tube, is made of alumina (Al2O3) material.

1. Industrial ceramic pipes are made of advanced alumina and have excellent heat and chemical resistance.

2.The design of industrial ceramic pipeshas excellent heat transfer performance.

3. Industrial ceramic pipesare customizable and easy to install, making them an excellent choice for various engineering applications.

4. The design of industrial ceramic pipeshas durability and long-term usability, ensuring that you get the maximum return from your investment.

Alumina ceramic

99.3% alumina ceramic, also known as high-purity alumina, is exceptionally strong and has excellent mechanical properties. Its strength can be attributed to several factors:

Hardness: Alumina ceramics are extremely hard, ranking high on the Mohs scale of mineral hardness. This hardness contributes to their strength and resistance to wear and abrasion.

Stiffness: Alumina ceramics have high stiffness and are rigid materials, which enhances their strength and ability to withstand mechanical stresses without deforming.

High Temperature Resistance: They can withstand high temperatures without losing their mechanical properties, making them suitable for use in high-temperature environments where other materials would fail.

Chemical Resistance: Alumina ceramics are highly resistant to chemicals, acids, and alkalis, which adds to their durability and strength in harsh operating conditions.

Electrical Insulation: They exhibit excellent electrical insulation properties, making them ideal for applications requiring electrical insulation combined with mechanical strength.

Low Thermal Expansion: Alumina ceramics have a low coefficient of thermal expansion, meaning they do not expand or contract significantly with temperature changes. This property contributes to their dimensional stability and strength in varying thermal conditions.

Corrosion Resistance: They are resistant to corrosion, rust, and oxidation, which further enhances their longevity and strength in corrosive environments.

Overall, 99.3% alumina ceramic is known for its exceptional strength, hardness, stiffness, and resistance to various environmental factors, making it a preferred choice for demanding applications in industries such as aerospace, automotive, electronics, and medical equipment manufacturing.

Application of industrial ceramic pipes

1. Industrial ceramic pipesare used as support tubes for high-temperature kilns.

2. Using industrial ceramic pipesas insulated thermocouple tubes can provide more accurate temperature measurements.

3. Using industrial ceramic pipes as connecting pipes for outdoor garden sprinkler heads can better resist the corrosion of chemicals in the soil.

Alumina Tube(open both ends)(slip casting) Specification Table

Number | SPEC: OD x ID |

LENGTH MM |

Number | SPEC: OD x ID |

LENGTH MM | ||

INCH | MM | INCH | MM | ||||

1 | 0.197x0.118 | 5x3 | ≤800 | 32 | 1.126x0.886 | 28.6x22.5 |

≤1800 |

2 | 0.236x0.157 | 6x4 |

≤1300 | 33 | 1.181x0.827 | 30x21 | |

3 | 0.250x0.125 | 6.4x3.2 | 34 | 1.181x0.906 | 30x23 | ||

4 | 0.250x0.157 | 6.4x4 | 35 | 1.260x0.984 | 32x25 | ||

5 | 0.250x0.188 | 6.4x4.8 | 36 | 1.375x1.125 | 34.9x28.6 | ||

6 | 0.276x0.157 | 7x4 | 37 | 1.378x1.063 | 35x27 | ||

7 | 0.276x0.197 | 7x5 | 38 | 1.496x1.181 | 38x30 | ||

8 | 0.315x0.197 | 8x5 | 39 | 1.575x1.181 | 40x30 | ||

9 | 0.354x0.236 | 9x6 |

≤1600 | 40 | 1.654x1.339 | 42x34 | |

10 | 0.375x0.250 | 9.6x6.4 | 41 | 1.750x1.500 | 44.5x38.1 | ||

11 | 0.394x0.236 | 10x6 | 42 | 1.811x1.496 | 46x38 | ||

12 | 0.394x0.276 | 10x7 | 43 | 1.875x1.625 | 47.6x41.3 | ||

13 | 0.433x0.276 | 11x7 | 44 | 1.969x1.575 | 50x40 | ||

14 | 0.472x0.236 | 12x6 | 45 | 2.000x1.750 | 50.8x44.5 | ||

15 | 0.472x0.315 | 12x8 | 46 | 2.250x2.000 | 57.2x50.8 | ||

16 | 0.472x0.355 | 12x9 | 47 | 2.283x1.890 | 58x48 | ||

17 | 0.500x0.250 | 12.7x6.4 | 48 | 2.362x1.96 | 60x50 | ||

18 | 0.500x0.375 | 12.7x9.5 | 49 | 2.500x2.250 | 63.5x57.2 | ||

19 | 0.551x0.394 | 14x10 | 50 | 2.559x2.165 | 65x55 | ||

20 | 0.591x0.394 | 15x10 |

≤1800 | 51 | 2.750x2.500 | 69.9x63.5 | |

21 | 0.630x0.472 | 16x12 | 52 | 2.756x2.362 | 70x60 | ||

22 | 0.669x0.472 | 17x12 | 53 | 2.956x2.561 | 75x65 | ||

23 | 0.688x0.437 | 17.5x11.1 | 54 | 3.000x2.750 | 76x70 | ||

24 | 0.750x0.512 | 19.1x13 | 55 | 3.150x2.675 | 80x68 | ||

25 | 0.787x0.591 | 20x15 | 56 | 3.500x3.125 | 88.9x79.4 |

≤1600 | |

26 | 0.866x0.630 | 22x16 | 57 | 3.543x3.150 | 90x80 | ||

27 | 0.866x0.669 | 22x17 | 58 | 3.937x3.543 | 100x90 | ||

28 | 0.945x0.709 | 24x18 | 59 | 4.000x3.650 | 101.6x93 | ||

29 | 1.000x0.750 | 25.4x19.1 | 60 | 4.331x3.937 | 110x100 |

≤1500 | |

30 | 1.063x0.669 | 27x17 | 61 | 4.500x4.125 | 114.3x105 | ||

31 | 1.063x0.787 | 27x20 | 62 | 4.724x4.331 | 120x110 | ||

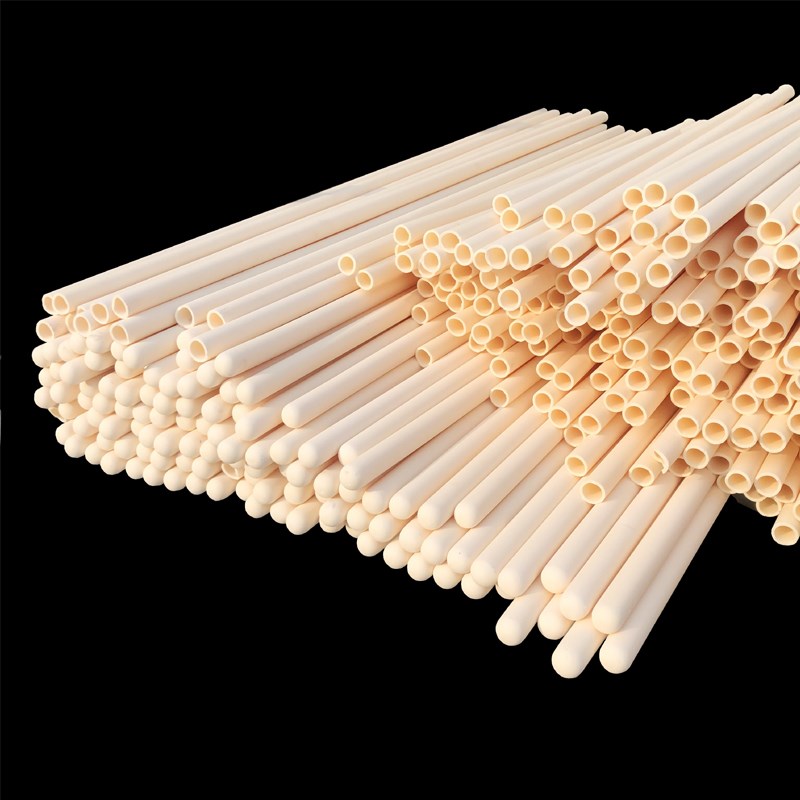

Insulation tube (extrusion) Specification Table

Number | 1 Bore tube SPEC: OD x ID | LENGTH MM | |

INCH | MM | ||

1 | 0.031x0.011 | 0.8x0.3 |

≤18500 |

2 | 0.039x0.019 | 1x0.5 | |

3 | 0.059x0.024 | 1.5x0.6 | |

4 | 0.079x0.039 | 2x1 | |

5 | 0.100x0.050 | 2.5x1.3 | |

6 | 0.118x0.059 | 3x1.5 | |

7 | 0.118x0.079 | 3x2 | |

8 | 0.125x0.063 | 3.2x1.6 | |

9 | 0.157x0.079 | 4x2 | |

10 | 0.197x0.118 | 5x3 | |

11 | 0.236x0.118 | 6x3 | |

12 | 0.236x0.157 | 6x4 | |

13 | 0.250x0.125 | 6.4x3.2 | |

14 | 0.250x0.157 | 6.4x4 | |

15 | 0.250x0.188 | 6.4x4.8 | |

16 | 0.276x0.197 | 7x5 | |

17 | 0.315x0.197 | 8x5 | |

18 | 0.354x0.236 | 9x6 | |

19 | 0.374x0.250 | 9.5x6.35 | |

20 | 0.394x0.236 | 10x6 | |

21 | 0.433x0.276 | 11x7 | |

22 | 0.472x0.315 | 12x8 | |

Alumina ceramic performance index (Notice of Correct in Leakeage Rate)

NO. | Property | Unit | Alumina |

1 | Al2O3 | % | >99.3 |

2 | SiO2 | % | — |

3 | Density | g/cm3 | 3.88 |

4 | Water absorption | % | 0.01 |

5 | Compressive strength | MPa | 2300 |

6 | 20℃ leakage rates | Torr・L/sec | >10-11=1.33322×10-12Pa・m3/sec |

7 | Twisting in high temperature | mm | 0.2 allowed in 1600℃ |

8 | Bonding in high temperature | not bonded in 1600℃ | |

9 | 20—1000℃ coefficient of thermal expansion | mm.10-6/℃.m | 8.2 |

10 | Thermal conductivity | W/m.k | 25 |

11 | Electric insulation strength | KV/mm | 20 |

12 | 20℃direct current insulation resistance | Ohm/cm | 1014 |

13 | High-temperature insulation resistance | 1000℃ MΩ | ≥0.08 |

1300℃ MΩ | ≥0.02 | ||

14 | Thermal shock resistance | 4 times not cracked in 1550℃ | |

15 | Maximum working temperature | ℃ | 1800 |

16 | Hardness | Mohs | 9 |

17 | Flexural strength | Mpa | 350 |

Properties of Alumina Ceramic

Alumina Ceramic are the most highly regarded and widely used of the ceramic products. It is non-conductive, resistant to corrosion, and are perfect for electrical insulation.

Alumina Ceramic has proven to be the best ceramic for protection of vital electrical components. It can be processed as tubing, sheets, bars, rods, discs, and many other forms depending on the requirements of the project.

AH100a Alumina Ceramic is configured to protect high voltage circuits.

Application of Alumina Ceramics

1.Because of their excellent chemical stability, alumina ceramics are used widely in acid-resistant pump impellers, pump bodies, acid-carrying pipe linings and valves.

2.Alumina ceramics are used in the manufacture of textile wear parts and knives. This is due to their extreme hardness and wear resistance.

3.Alumina is the most commonly used abrasive grain in the woodwork and metalwork industry. This is because it does a better job than silicon carbide on several materials, including bare wood, painted surfaces, and metal.

4.Alumina ceramic materials are used in making spark plugs, which are useful in a wide variety of engines.

5.Transparent alumina ceramics are used in making high-pressure sodium lamps and infrared detection window material.

6.With an alumina content higher than 99%, alumina ceramics can be used as excellent electrical insulators. They also have a low dielectric loss, with a wide range of applications in electronics and electrical appliances.

7.Transparent alumina shows good permeability to visible light and infrared rays.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of alumina ceramics. For more information, please visit https://www.aluminapipe.com/.

Our factory

Jinzhou Yunxing Industrial Ceramics Co., Ltd. was established in 2000, mainly producing various types of tubular ceramic products and various industrial parts with alumina content above 99.3%. The factory covers an area of 4000 square meters.

The company's main products are: alumina ceramic tubes, alumina ceramic crucibles, alumina ceramic rods, alumina ceramic boats, alumina ceramic plates, alumina ceramic parts, etc.

The company currently has 3 1800 ° C high-temperature furnaces and 2 1400 ° C low-temperature kilns independently designed and manufactured. The molding process is mainly based on grouting molding, and has other molding process equipment such as extrusion and hot die casting.

The company has 105 employees, including one senior ceramic engineer, three engineers, six overseas sales staff, and four professional after-sales staff.

FAQ

Please provide the specifications of the ceramic tube, such as shape, size, quantity, purpose, etc.

There are several different types of aluminum oxide tubes, including furnace tubes, thermocouple tubes, and high-temperature tubes. You can also customize specialized size tubes.

Alumina is a very hard ceramic that is excellent at resistance abrasion and is ideal for wear resistant inserts or products.

The delivery cycle of alumina tubes depends on the required size and quantity. Please contact us for more information.

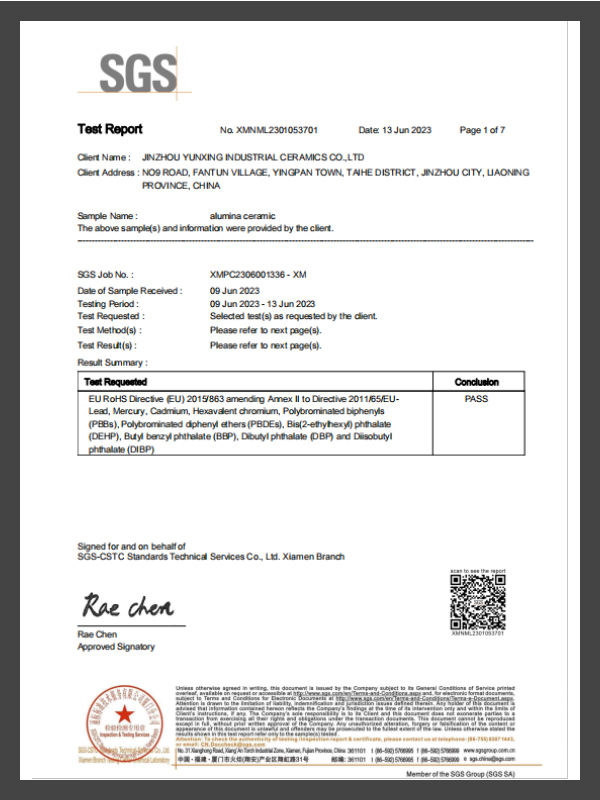

Certification

Feedback

1. If you have any questions or questions, please contact us and we will communicate with you as soon as possible.

2. For any other satisfaction, please also feedback to us to make our service better and better.