ceramic tube

-

High Purity Alumina Ceramic Tube

1.Exceptional Purity: High purity alumina ceramic tubes boast a purity level of 99% or above, ensuring minimal impurities and superior performance in critical applications. 2.Mechanical Strength: These tubes exhibit excellent mechanical strength, enabling them to withstand high temperatures and harsh operating conditions without deformation or structural failure. 3.Thermal Stability: With outstanding thermal stability, high purity alumina ceramic tubes can endure rapid temperature changes without compromising performance, making them suitable for thermal management applications. 4.Chemical Resistance: Their inherent resistance to chemical corrosion ensures longevity and reliability in corrosive environments, making them ideal for use in chemical processing, semiconductor manufacturing, and other corrosive applications.

Email Details -

Alumina ceramic tube (internal thread)

The customer found us through our company's website. Sent us an email and attached the drawings.

Email Details -

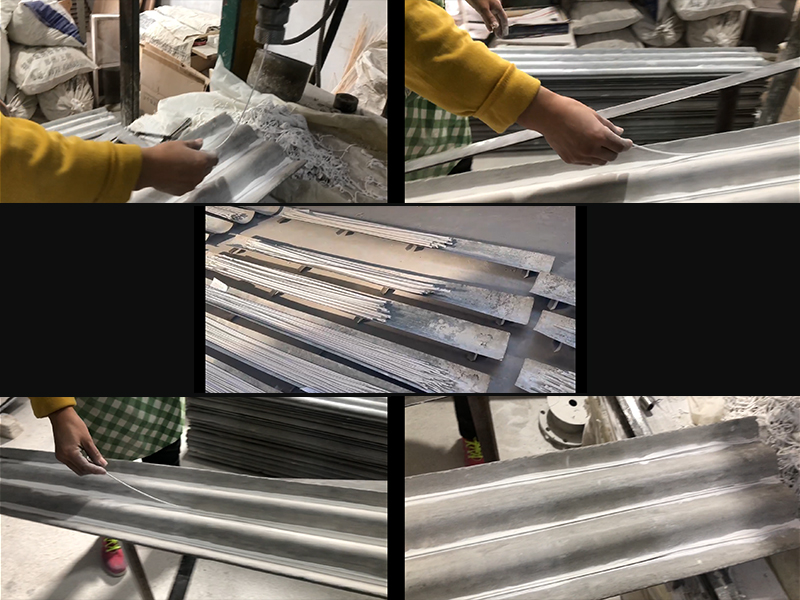

Alumina ceramic tube (extrusion process)

Squeeze forming method: This forming technology has a simple shape and is limited to workpieces with an internal thickness exceeding 1mm and a diameter and length of 4:1 or less.

Email Details

-

0805-2024

Comparative Analysis of Various Grades of Alumina Ceramic Tubes and Their Price-Performance Ratio

Alumina ceramic tubes are widely used in various industrial applications due to their excellent thermal and mechanical properties. However, choosing the right grade of alumina ceramic tubes can significantly impact both performance and cost-effectiveness. In this article, we delve into a comparative analysis of different grades of alumina ceramic tubes and evaluate their price-performance ratio.

-

0605-2024

Comparing Alumina Ceramic Tubes: Grades, Performance, Prices

In the realm of industrial ceramics, alumina ceramic tubes stand out as versatile and indispensable components across various applications. From high-temperature furnaces to semiconductor manufacturing, these tubes play a crucial role in providing thermal insulation, corrosion resistance, and electrical insulation. However, navigating through the myriad of grades, performance metrics, and price differentials can be daunting for industry professionals seeking the optimal solution for their specific needs.