Against the backdrop of the global "dual carbon" strategy and the transformation of the automotive industry towards lightweighting, electrification, and environmental protection, the innovative application of high-performance materials has become the key to enhancing the core competitiveness of automobiles. 99.3% alumina ceramics, as a typical representative of industrial grade high-purity ceramic materials, have continuously expanded their application scenarios in the automotive industry due to their balanced physical and chemical properties, excellent environmental adaptability, and full lifecycle environmental protection characteristics. They provide efficient solutions to solve the pain points of traditional metal materials such as heavy weight, easy wear, and insufficient high temperature resistance.

The core advantage of 99.3% alumina ceramics in the automotive industry

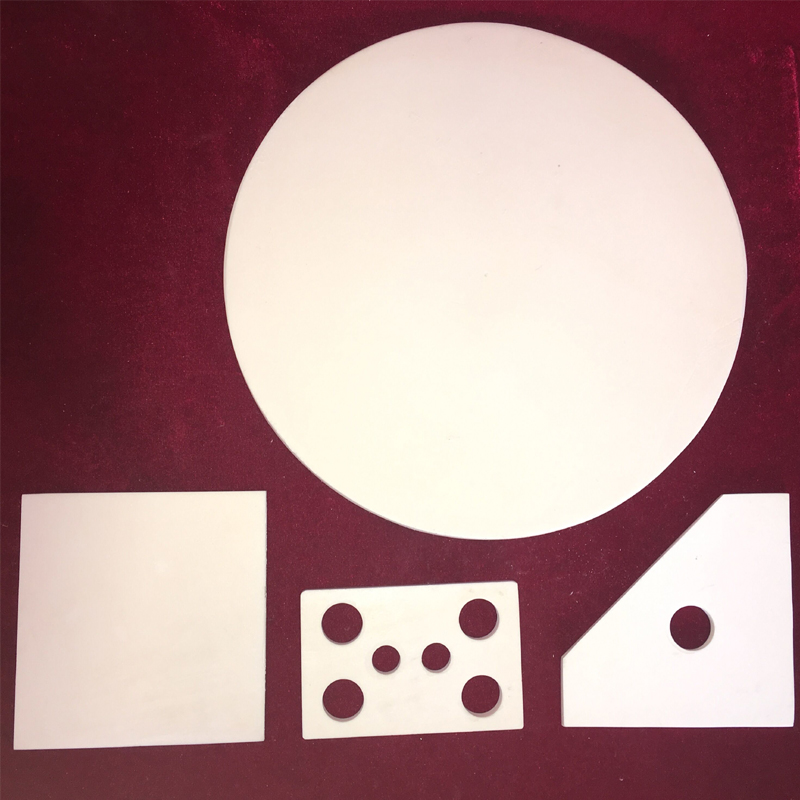

99.3% alumina ceramics are made from alumina with a purity of ≥ 99.3% as the core raw material, through precision molding and high-temperature sintering. Their performance is between industrial grade medium purity ceramics and high-purity ceramics, with both cost-effectiveness and high-performance advantages. They can be summarized into the following five points:

(1) Significant lightweight characteristics, helping to save energy and reduce emissions

Lightweight is the core path for automobiles to achieve energy conservation and emission reduction. Data shows that for every 10% reduction in vehicle weight, fuel consumption of fuel vehicles can be reduced by 6% -8%, and the range of new energy vehicles can be increased by 5% -10%. The density of 99.3% alumina ceramics is about 3.8g/cm ³, which is only about half of steel and much lower than traditional metal materials. Replacing some metal components with it can significantly reduce the overall weight of the vehicle while ensuring structural strength, especially reducing the unsprung mass, improving the acceleration, braking, and steering response sensitivity of the vehicle, and directly reducing energy consumption, which meets the energy efficiency improvement needs of the automotive industry.

(2) Excellent high temperature resistance and thermal stability, suitable for harsh working conditions

The core components of automobile engines, braking systems, exhaust treatment systems, etc. are subjected to harsh working conditions of high temperature and alternating cold and hot conditions for a long time, which puts extremely high demands on the high-temperature resistance of materials. 99.3% alumina ceramics can work stably for a long time below 1600 ℃, with a low coefficient of linear expansion (about 7.6 × 10 ⁻⁶/℃), excellent thermal shock resistance, and are not easily deformed or failed in scenarios such as instantaneous high-temperature impact during engine start-up and high-temperature braking friction. Compared to traditional metal materials, its high temperature stability can significantly extend the service life of core components and reduce maintenance costs.

(3) High hardness and outstanding wear resistance, reducing wear and tear costs

The Mohs hardness of 99.3% alumina ceramics is as high as level 9, and the bending strength is ≥ 330MPa, far superior to ordinary metals and engineering plastics. In high-frequency friction or force scenarios such as automotive transmission and braking, its wear resistance is 3-5 times that of traditional metal components, which can significantly reduce the wear and tear of components. For example, the service life of ceramic bearings can reach over 500000 kilometers, far exceeding the 150000 kilometers of traditional metal bearings. This not only reduces maintenance and replacement costs for users, but also reduces the generation of waste parts.

(4) Excellent electrical insulation and chemical stability ensure system safety

99.3% alumina ceramics have a volume resistivity of ≥ 10 ¹⁴Ω· cm and a breakdown strength of ≥ 25kV/mm. They have stable insulation in high voltage and high frequency environments without the risk of arc breakdown, making them an ideal choice for insulation components in automotive electronic systems. At the same time, its chemical stability is extremely strong, resistant to acid, alkali, and organic solvent corrosion, and does not react with industrial media such as automobile exhaust and lubricating oil. It can work stably in corrosive environments for a long time, ensuring the safe operation of various systems in automobiles.

(5) Environmental protection throughout the entire lifecycle, in line with the concept of green development

From production, use to recycling, 99.3% alumina ceramics have demonstrated significant environmental advantages. In the production process, the raw material is natural alumina ore, which has abundant and renewable resources. The energy consumption and pollutant emissions during mining and processing are much lower than those during the smelting process of metal materials such as steel and aluminum alloys; In terms of usage, the long-life feature reduces resource consumption and waste generation; In the recycling process, waste ceramic components can be recycled as raw materials after being crushed and purified, and will not release harmful substances in the natural environment, without polluting the soil and water sources.