-

Alumina ceramic tube (extrusion process)

Squeeze forming method: This forming technology has a simple shape and is limited to workpieces with an internal thickness exceeding 1mm and a diameter and length of 4:1 or less.

Details -

Production of alumina ceramic boats

The alumina ceramic boat is made using slip casting technology. Slip casting molding is actually a molding method that has been used for alumina ceramics for a long time. Because gypsum molds are mainly used, the cost is relatively low and it is also relatively easy to form. Even if the size and shape are complex, it is relatively easy to form. However, the key to slip casting molding is still the manufacturing equipment of alumina slurry.

Details -

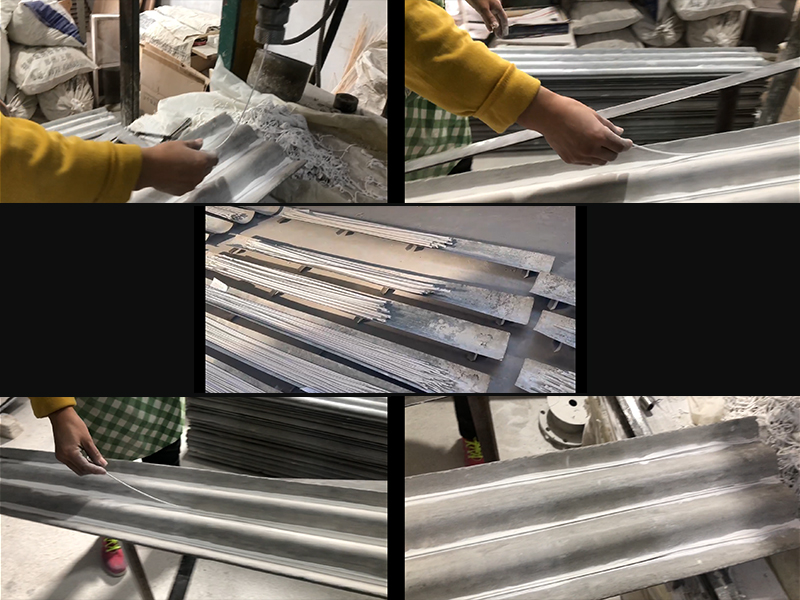

Finished product screening

The drying of the pipes is completed, and the workers conduct preliminary screening. Confirm the quantity of qualified products.

Details -

Large diameter alumina ceramic tube semi-finished products

Sintering: Sintering the dried body, usually using high-temperature sintering method. Sintering temperature and time depend on the product

Details -

DemoldingSemi-finished integrated pipe

Drying: Dry the formed green body, usually using natural drying or oven drying methods to remove moisture from the green body forming

Details -

Slip casting and drying process

Slip casting molding is actually a molding method that has been used for alumina ceramics for a long time. Because gypsum molds are mainly used, the cost is relatively low and it is also relatively easy to shape.

Details