Menu

- Home

- Products

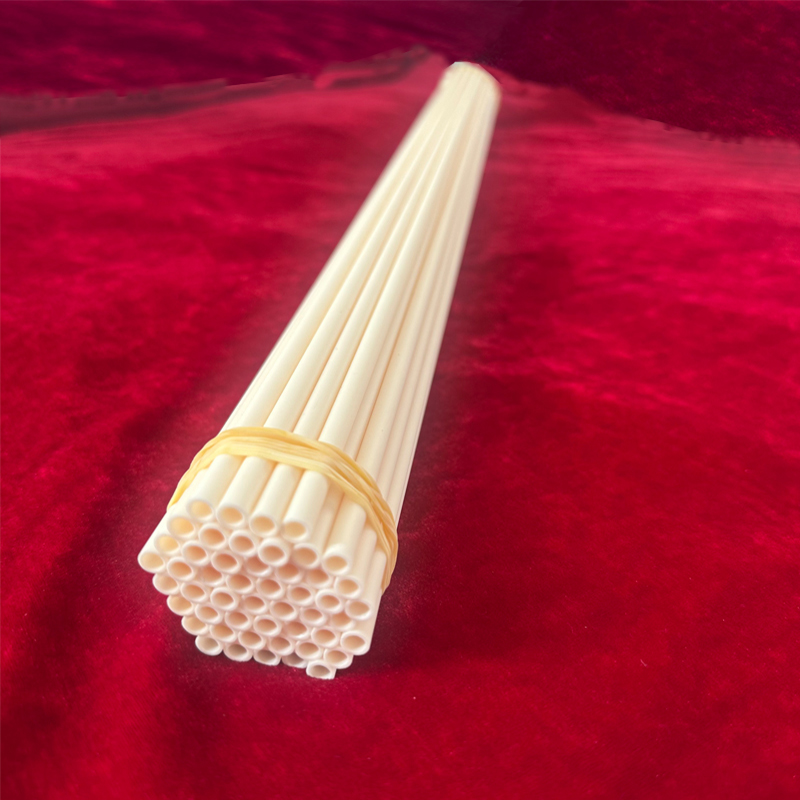

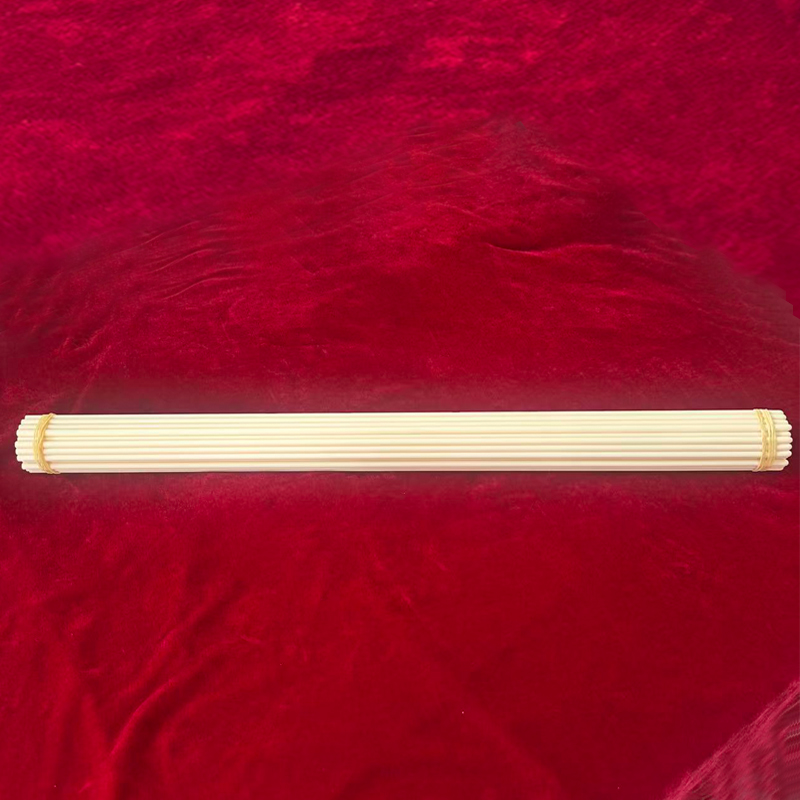

- Alumina Ceramic Tube

- Alumina Ceramic Crucible

- Alumina Rectangular Trays

- Alumina Ceramic Rods

- Alumina Ceramic Plate

- Alumina Ceramic Beads

- Alumina Ceramic Parts

- News

- Company News

- Product News

- INDUSTRY

- Factory Show

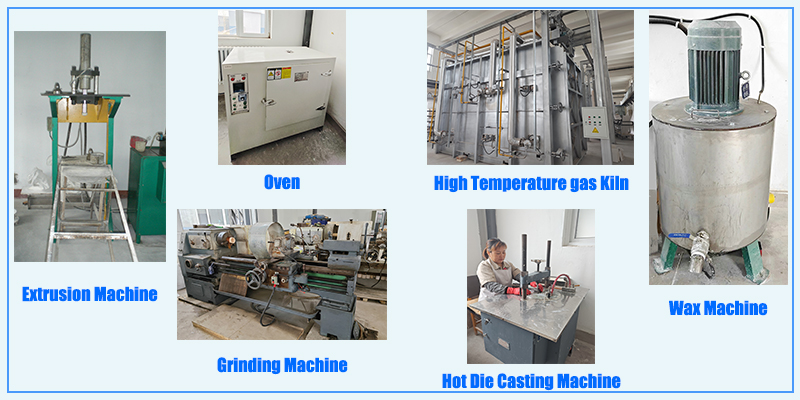

- Factory Scale

- Process Flow

- Customized Process

- Contact Us

- About Us

- Company Style

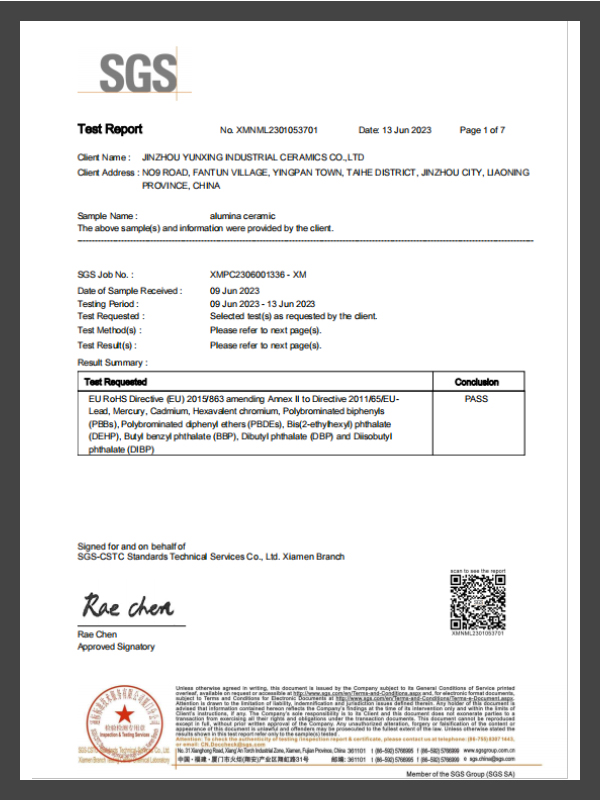

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

- VIDEO

Search