In a semiconductor single-crystal silicon growth furnace, the temperature surges from room temperature to over 1,600°C in an instant; in a metal smelting workshop, scalding molten metal is rapidly poured into crucibles, which may then be placed in a cooling environment — such drastic temperature changes are like repeated "thermal quenching" tests, posing severe challenges to the thermal shock resistance of the materials that bear them. In this silent "battle between heat and cold," alumina (Al₂O₃) crucibles have emerged as "cold-faced warriors" safeguarding the stable operation of high-temperature processes, thanks to their exceptional thermal shock resistance.

Core code: Low expansion, high thermal conductivity, high strength

The thermal shock resistance of alumina crucibles stems from the unique physical properties of the alumina crucibles itself. First, alumina has a low coefficient of thermal expansion (about 8×10⁻⁶/℃), minimizing expansion/contraction during drastic temperature changes and reducing internal stresses caused by volume fluctuations. Second, its good thermal conductivity (about 25 W/m·K) enables rapid and uniform heat distribution, preventing stress concentrations from local temperature gradients.

Process refinement: Optimization of purity and microstructure

In addition to the intrinsic properties of the material, advancements in modern manufacturing processes have significantly enhanced the thermal shock resistance limit of alumina crucibles. The use of high-purity raw materials (such as alumina purity of over 99%) has drastically reduced the presence of low-melting-point impurity phases, which are often weak links and crack sources at high temperatures. Advanced sintering technologies (such as hot-pressing sintering and isostatic pressing) enable the formation of a microstructure with fine, uniformly distributed grains and extremely high density. This dense and uniform structure not only withstands higher thermal stresses but also effectively hinders the initiation and propagation paths of cracks, elevating the "thermal shock resistance" capability to new heights.

Industrial foundation: From laboratory to production line

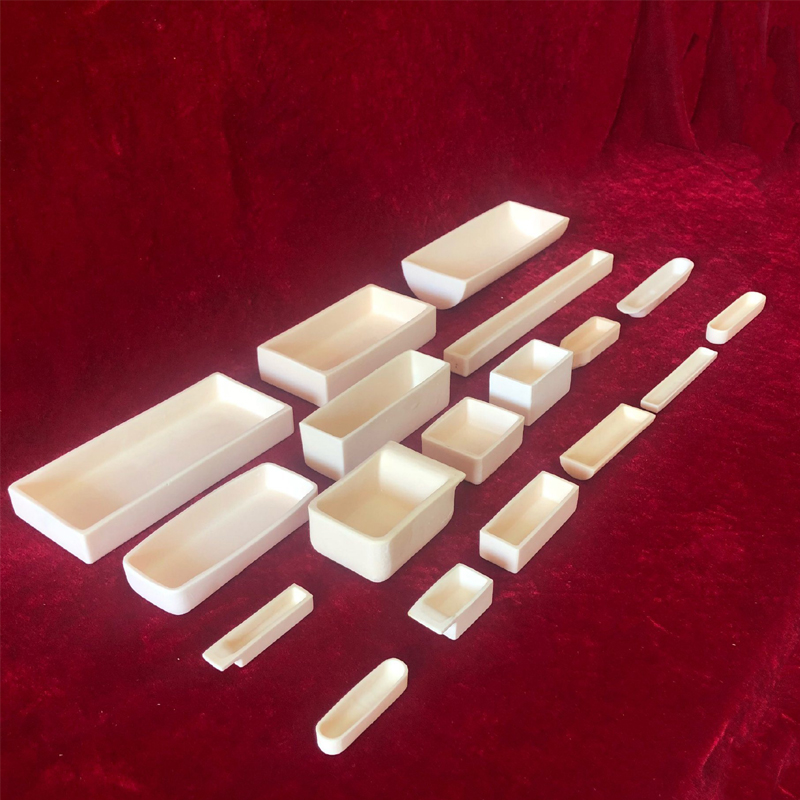

The exceptional thermal shock resistance makes alumina crucibles an irreplaceable key consumable in extreme thermal environments. In the semiconductor industry, they support the growth of single crystals such as silicon and gallium arsenide, where repeated heating and cooling cycles in furnaces pose severe tests to the crucibles. Special metal and alloy smelting (such as titanium, zirconium, and platinum-group metals) also relies on them, as the high temperature of molten metals and subsequent cooling processes require crucibles to have (extremely strong) thermal shock resistance. In the fields of new material research and high-temperature chemical analysis, alumina crucibles are the first-choice containers for high-temperature reactions and sample melting in laboratories, with their reliability directly influencing the accuracy and repeatability of experimental results.

"During the growth of monocrystalline silicon, the temperature gradient in the furnace is extremely large, and the heating and cooling rates are strictly regulated," said the technical director of a leading domestic semiconductor material enterprise. "Alumina crucibles with high purity and high density, owing to their excellent thermal shock resistance, are crucial for ensuring the stability of the crystal growth process and reducing the contamination of expensive silicon materials and damage to the furnace body caused by crucible breakage. This directly affects our production efficiency and cost control."

As high-end manufacturing and cutting-edge technology fields increasingly rely on high-temperature processes, the requirements for the performance of load-bearing materials have also risen significantly. With its exceptional thermal shock resistance, alumina crucibles have become an indispensable "unsung hero" in modern high-temperature industries. In the future, through continuous optimization of material formulations (such as introducing specific additives), nanoscale regulation of microstructures, and the application of more precise manufacturing processes, the thermal shock resistance of alumina crucibles is expected to achieve new breakthroughs. This will provide a more robust and reliable foundation for humanity to explore material preparation and process innovation in higher-temperature and more extreme environments.