High-purity alumina ceramic plates are currently widely used substrate materials due to their advantages such as mature production and processing technology, low cost, good thermal shock resistance, excellent electrical insulation, and favorable metal adhesion. They are also extensively applied in electronic payload units of spacecraft, including on-board microwave signal transmission channels, carrier for mounting active components, and heat dissipation channels for power chips. As the most basic units composing a spacecraft, the performance level of spacecraft materials directly affects the on-orbit reliability of the spacecraft. Therefore, the properties of high-purity alumina ceramic plates are crucial to the operation of spacecraft.

However, the following issues often arise during the preparation process of high-purity alumina ceramic plates:

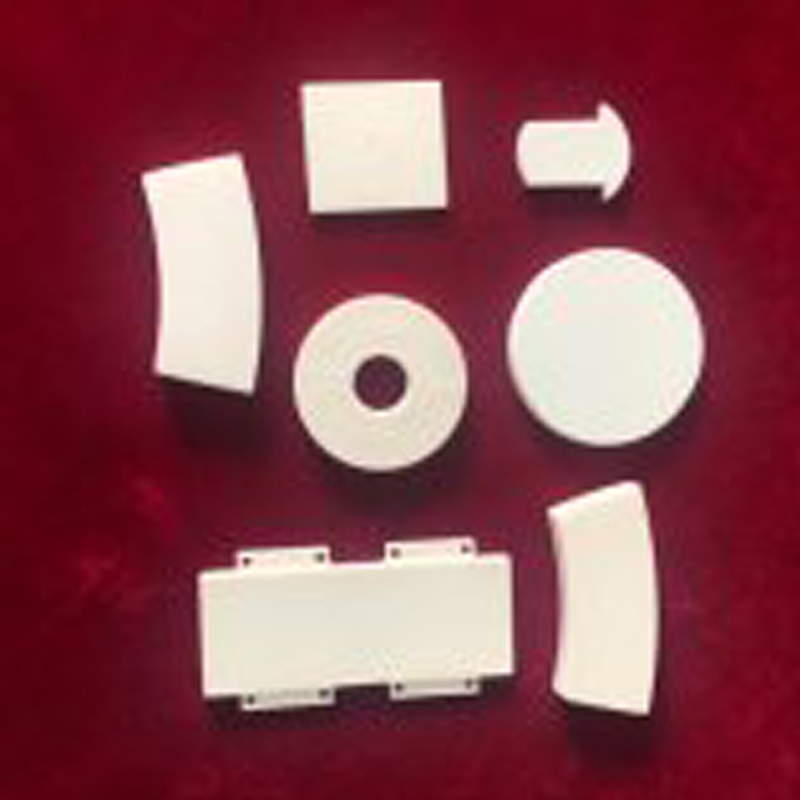

❶High-purity alumina ceramic plates, which are produced from high-purity alumina powder through multiple complex processes including tape casting, drying and cutting, multi-layer lamination, isostatic pressing, and sintering, will have increased dielectric loss if their material purity is low, ultimately leading to a decline in circuit performance.

❷If the material has low mechanical strength, it will cause problems such as cracks and material body peeling in thin-film circuit products during the assembly and testing processes.

❸Surface defects of ceramic plates can lead to quality issues such as deteriorated local adhesion of the circuit film layers fabricated on them and burrs at the edge of lines. These problems affect the quality of circuit signals and may even result in foreign debris in the product.

Key points for preparing high-purity alumina ceramic plate

①Optimization of solvent system for casting slurry

Different solvent systems exhibit varying adaptability to the environment and can affect the solid content of the prepared slurry, the surface condition of the tape-cast film, and the film-forming effect. Under the premise that the dispersant, binder, and plasticizer are fixed, there are significant differences in the tape-casting molding states among different solvent systems.

②Thickness control of cast film

The thickness of a single-layer tape-cast film affects the thickness tolerance of the final substrate. The thickness of the tape-cast film is mainly influenced by the slurry state and the height of the tape-casting doctor blade. As the solid content of the tape-casting slurry increases, the average density of the sintered substrate gradually increases, and the shrinkage rates in the width and thickness directions tend to stabilize. Based on this rule, fine-tuning the solid content and sintering temperature enables precise control of the final dimensions of the sintered substrate.

③ Appearance and flatness control of substrate

Good appearance and flatness are the foundation for the engineering application of high-purity alumina ceramic plates. There are many factors that affect the appearance and flatness of the substrate, among which lamination, debonding, and sintering are the key processes.

● Stacking process control of cast film.

To avoid surface defects and flatness issues of tape-cast films during the lamination and warm isostatic pressing (WIP) processes, the following approaches have been determined through multiple experimental comparisons:

Adopt wide film strip lamination, and after isostatic pressing, cut the middle part to avoid defects and uneven areas at the edges of the tape-cast film strips;Use tempered glass plates as lamination carriers, lay the green tape-cast films flat on the tempered glass plates, and during lamination, ensure that the upper and lower surfaces of each film strip removed from the carrier tape maintain a consistent orientation.Measures such as the use of tempered glass carriers significantly reduce micro-defects on the film surface and effectively improve the appearance quality and flatness.

● Control of raw material debonding process.

The function of debonding is to remove organic matter from the green body. In order to effectively utilize the furnace space and solve the problems of warping and cracking during the debonding process of the raw material, the stacking debonding method is adopted for the damaged substrate in the furnace. After multiple experiments, it has been shown that the laminated without cover mode can balance efficiency and prevent warping and cracking. By adopting a laminated+without cover debonding method, the number of layers in the debonding process has been further optimized, and the highest number of layers has been determined to be 5.

● Sintering process control.

Sintering is a crucial process in the preparation of alumina ceramic plates. Due to the high sintering temperature, impurities are prone to carbonization. To avoid substrate contamination, the selection of cover plates and pads is important. After testing, it was determined that the cover plate is made of porous high-purity alumina ceramic, and the pad plate is made of dense high-purity alumina ceramic. Both require ultrasonic cleaning before use.