In a recent groundbreaking study, scientists have delved deep into the complex relationship between crucible materials and the kinetics of thermal reactions. The findings not only shed light on fundamental chemical processes but also have far - reaching implications for various industries, from materials science to metallurgy.

Thermal reactions are at the heart of countless industrial and scientific processes. The rate at which these reactions occur, known as reaction kinetics, is influenced by multiple factors, and the crucible material has emerged as a critical determinant. A crucible, which is used to hold substances during heating, can interact with the reactants in ways that either accelerate or impede the reaction.

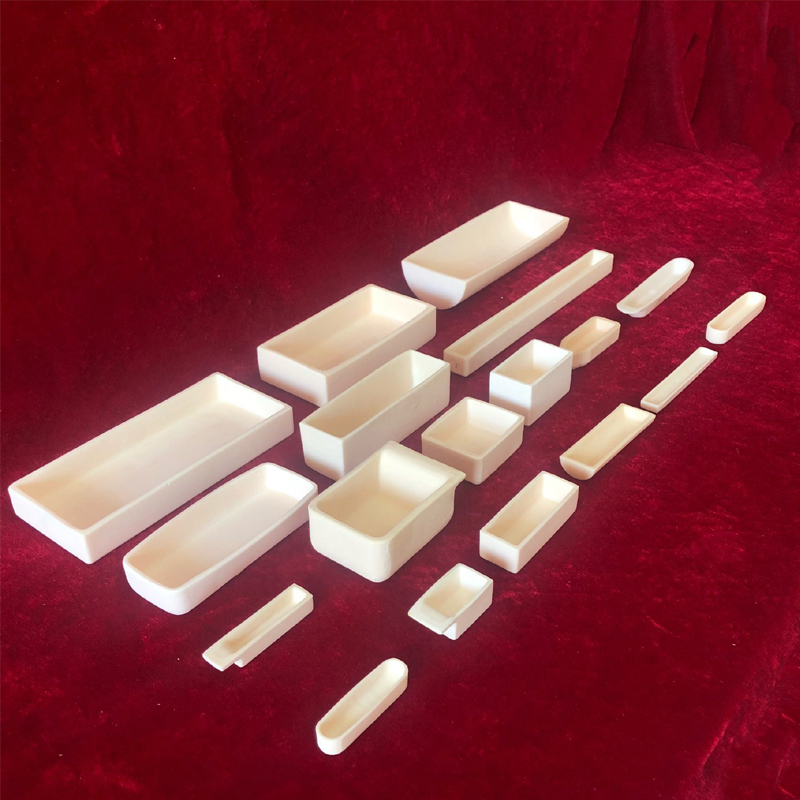

Among the various crucible materials investigated, alumina ceramic crucibles have shown extraordinary properties. Alumina ceramics are known for their high melting point, excellent chemical stability, and low thermal conductivity. These characteristics make them an ideal choice for thermal reactions.

During the study, researchers found that when using alumina ceramic crucibles, the thermal reactions exhibited more predictable and consistent kinetics. The high chemical stability of the alumina ceramic prevented unwanted chemical reactions between the crucible and the reactants. This meant that the reaction proceeded as expected, without interference from side reactions caused by crucible - reactant interactions. For example, in high - temperature synthesis of advanced materials, where precise control of the reaction rate is crucial, alumina ceramic crucibles provided a stable environment that allowed for accurate manipulation of the reaction kinetics.

Moreover, the low thermal conductivity of alumina ceramic crucibles helped in maintaining a more uniform temperature distribution within the crucible. This was especially important for reactions that are sensitive to temperature gradients. In metallurgical processes, such as melting and alloying of metals, a uniform temperature ensured that the reactions occurred evenly throughout the molten metal, leading to better - quality alloys.

The research also indicated that the surface properties of alumina ceramic crucibles played a role in influencing reaction kinetics. The smooth surface of these crucibles reduced the likelihood of reactant adhesion and subsequent interference with the reaction process. This made it easier for the reactants to move freely and interact with each other, promoting faster and more efficient reactions.

As industries continue to seek more efficient and precise thermal reaction processes, the importance of choosing the right crucible material cannot be overstated. Alumina ceramic crucibles, with their unique combination of properties, are set to revolutionize thermal reaction - based industries. They offer a reliable and cost - effective solution for controlling reaction kinetics, opening up new possibilities for the development of advanced materials and improved manufacturing processes.