In the fields of scientific research, metallurgy, and chemical engineering, alumina crucibles have become the core containers for high-temperature experiments due to their characteristics of high-temperature resistance and corrosion resistance. How to select the most suitable model from a wide range of products? This article will analyze the key points for purchase from multiple perspectives such as material, performance, and usage scenarios, helping you make a wise decision.

I. Core Performance: Dual Assurance of High Temperature Resistance and Chemical Stability

Alumina crucibles are made from high-purity Al₂O₃ as the raw material. They can withstand long-term high-temperature environments above 1600°C, and in the short term, the temperature can even reach up to 1800°C. They have excellent chemical stability and are corrosion-resistant to most acid, alkali, and salt solutions. They are particularly suitable for melting experiments of weakly alkaline substances (such as anhydrous Na₂CO₃). However, it should be noted that strong alkalis (such as NaOH), strong acids (such as K₂S₂O₇), and HF solutions may cause reactions, and contact with them should be avoided.

II. Key Points for Model Selection: Four Dimensions Matching Experimental Requirements

Purity Grading

The purity of mainstream products in the market ranges from 60% to 99%. Alumina Crucibles with high purity (such as 99%) have stronger thermal shock resistance and are suitable for high-precision experiments or scenarios with frequent temperature fluctuations. For example, a crucible with a purity of 99% can withstand a heating rate of 5°C per minute, reducing the risk of cracking.

Size and Shape

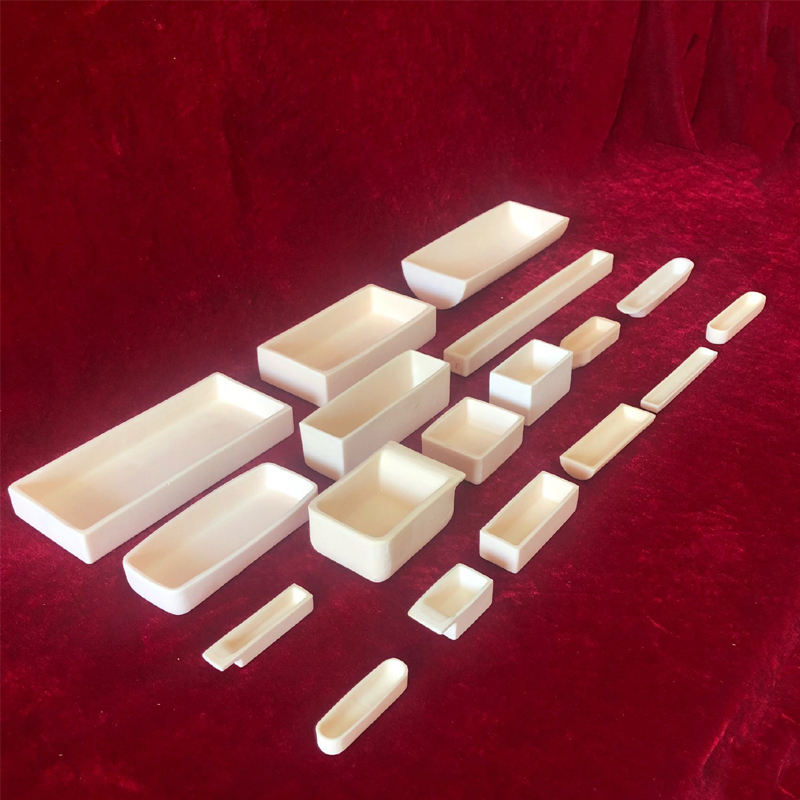

The capacity varies from 10ml to 250ml, and it is necessary to select according to the sample volume and the space of the equipment. Cylindrical alumina crucibles are suitable for uniform heating, while square alumina crucibles provide a larger surface area and are often used for the sintering of materials. In addition, the design with a lid can prevent sample contamination, and arc-shaped containers are convenient for pouring out the molten substances.

Temperature Resistance and Thermal Shock Performance

Pay attention to the long-term service temperature and short-term limit temperature indicated on the product. For example, the 99% alumina crucible is marked with a long-term temperature of 1600°C and a short-term temperature of 1800°C. At the same time, it is necessary to note the recommended heating/cooling rate (usually ≤ 5°C per minute) to avoid cracking caused by sudden cooling and heating.

Surface Treatment and Cleaning

The design of a smooth inner wall reduces the adhesion of residues, making it easy to clean. The inner walls of some products are glazed, which further enhances their corrosion resistance. It is recommended to let the alumina crucible cool naturally to room temperature before cleaning after use to avoid thermal shock caused by the temperature difference.

III. Considerations of Cost-effectiveness and Suppliers

In terms of price, products with high purity and customization features come with a relatively high cost. However, their long-term durability can reduce the frequency of replacement. It is advisable to give priority to manufacturers that provide spot goods in multiple specifications. For instance, some brands support the customization of alumina crucibles with special shapes, meeting the needs of special experiments. At the same time, evaluate the qualifications of suppliers. Give preference to enterprises that have obtained ISO certification or have cooperation cases with scientific research institutions to ensure product consistency and after-sales support.

IV. Usage Tips: Practical Techniques for Extending the Service Life of the Crucible

Regular Inspection: Observe whether there are cracks and replace the damaged crucible in a timely manner to avoid experimental accidents.

Conclusion

When selecting an alumina crucible, it is necessary to comprehensively consider the experimental conditions (temperature, chemical environment), sample characteristics (volume, reactivity), and budget. Give priority to high-purity alumina crucibles, those with suitable sizes, and reliable brands. Through scientific model selection and standardized operation, not only can the experimental accuracy be guaranteed, but also the return on investment in the equipment can be maximized.