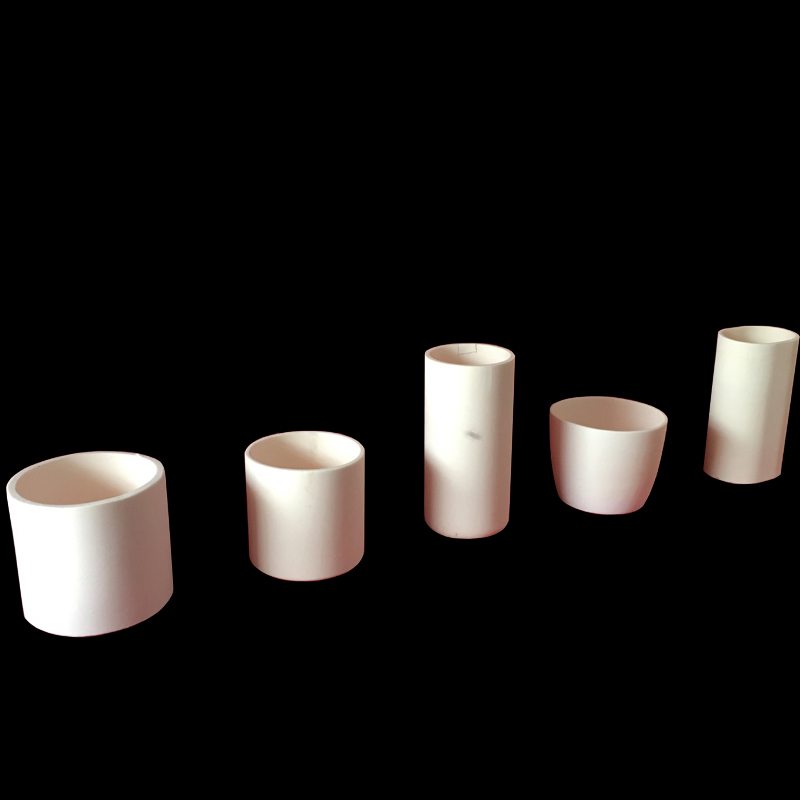

Precautions for firing the lead-silver powder in an alumina ceramic crucible:

1. Chemical reaction between lead and alumina ceramic

The oxide of lead (PbO) reacts with alumina ceramic (Al₂O₃) starting from 700 °C, producing low-melting-point compounds such as lead aluminate. This reaction will damage the structural integrity of the alumina ceramic crucible, cause the material to become brittle and may generate gases, ultimately leading to cracking and explosion. Especially when the lead content is high or the firing temperature approaches the temperature resistance limit of the alumina ceramic crucible (for example, the recommended long-term operating temperature is ≤1600 °C), the risk of the reaction increases significantly.

2. Thermal Stress and Temperature Control

The thermal expansion coefficient of alumina ceramics is relatively high (about 8.2×10⁻⁶/℃), and its thermal conductivity is relatively low (about 25 W/m·K). Sudden cooling and heating are likely to generate thermal stress. If the heating or cooling rate is too fast during the firing process, or the holding time is too long, resulting in local overheating, it may cause the internal cracks to expand and ultimately lead to cracking.

3. The Influence of Impurities or Volatile Substances

If the lead-silver powder contains impurities such as sulfur and chlorine, it may react with alumina at high temperatures to form volatile substances (such as HCl and SO₂), aggravating the corrosion of the crucible and the increase of internal pressure. In addition, the volatilization of lead (with a melting point of 327 °C) may also release gases at high temperatures, further increasing the risk of cracking.

Suggested improvement measures:

Select crucible materials resistant to corrosion by lead salts (such as platinum or nickel crucibles);

- Strictly control the firing temperature (it is recommended to be ≤1600°C) and adopt a slow heating and cooling program;

- Pre-treat the lead-silver powder to reduce the impurity content, or add stabilizers to inhibit the reaction between alumina and lead.