With the continuous evolution of furnace technology, industrial production has increasingly stringent performance requirements for the core components of furnaces. Among them, as a key component of the furnace, the quality and adaptability of alumina tubes directly affect the overall efficiency of the furnace. More and more industry pioneers are turning their attention to custom designed alumina tubes to meet their complex and unique furnace needs. So, what is the charm of custom designed alumina tubes that can stand out among many choices?

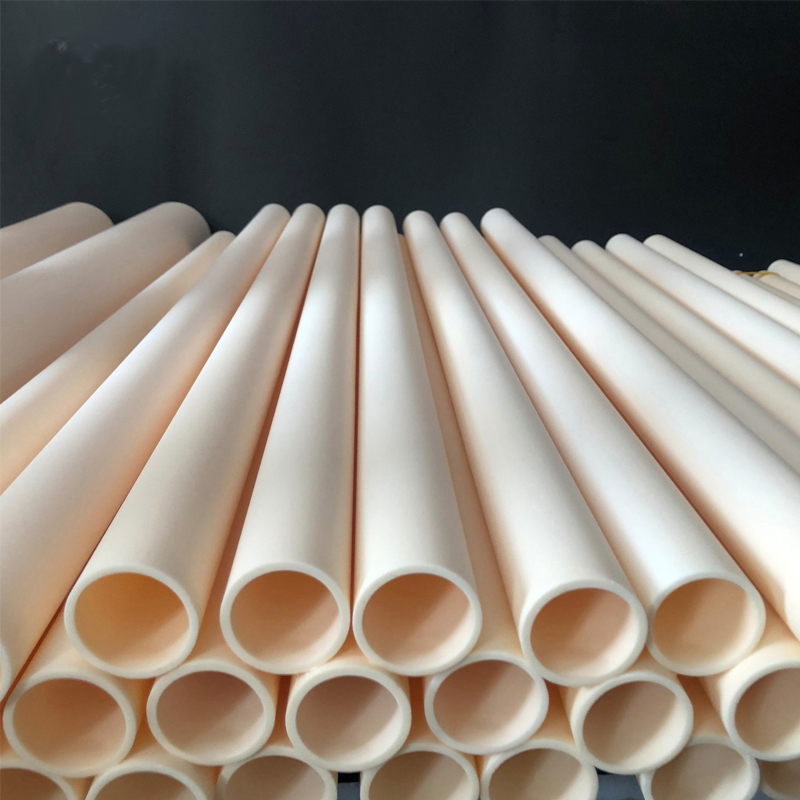

The biggest advantage of custom designed alumina tubes is their unparalleled precision adaptability. Each furnace has its specific operating environment, temperature range, gas flow rate, and other parameters. Standard specification alumina tubes often struggle to fully meet these complex and ever-changing requirements. Customized design can accurately create alumina tubes that perfectly match the specific size and working conditions of the furnace. From pipe diameter, wall thickness to length, every detail can be adjusted according to actual needs to ensure optimal performance of alumina tubes in the furnace, reducing energy waste and equipment loss caused by mismatches.

In terms of performance, customized alumina tubes are also impressive. In the professional customization process, the most suitable grade of alumina material will be selected, and its physical and chemical properties will be optimized through advanced manufacturing processes. For example, for high-temperature furnaces, alumina tubes with ultra-high heat resistance and thermal shock resistance can be customized to maintain structural stability even under frequent temperature fluctuations, greatly extending their service life. For furnaces with special chemical environment requirements, customized design can also endow alumina tubes with excellent chemical corrosion resistance, effectively resisting the erosion of various corrosive gases and substances.

In addition, custom designed alumina tubes can bring significant economic benefits to enterprises. Although the initial cost of customized products may be slightly higher than standard products, in the long run, their excellent performance and long service life can significantly reduce the frequency of equipment maintenance and replacement, and reduce production losses caused by equipment downtime. At the same time, the energy efficiency improvement brought by precise adaptation can also save considerable energy expenses for enterprises over time.

In today's pursuit of high efficiency, energy conservation, and stability in industrial production, custom designed alumina tubes are becoming the ideal choice to meet the needs of furnaces due to their unique advantages. Both emerging high-tech industries and traditional manufacturing can obtain new opportunities to improve production efficiency and optimize cost structure from customized alumina tubes. If you are also seeking solutions to improve the performance of your furnace, you may consider custom designed alumina tubes to open a new chapter in the efficient operation of your furnace.