① Alumina

In a broad sense, many people consider alumina as a general term for aluminum oxides, aluminum hydroxides, and the like, which are a class of compounds composed of aluminum, oxygen, and hydrogen.

Strictly speaking, however, alumina, namely aluminum oxide with the chemical formula Al₂O₃, is an oxide that ranks second only to silicon dioxide in terms of content in the earth's crust. It is widely found in minerals such as feldspar and mica. Industrially, it is often extracted from bauxite, a natural mineral raw material, to obtain alumina.

The crystal structure of alumina is complex, with many allotropes, which can be divided into more than ten crystal forms such as α, β, γ, δ, ε, ζ, η, θ, κ, λ, ρ, and χ. Among them, α-Al₂O₃ is a stable phase, while the other crystal forms are transition phases. All of these transition phases will transform into the α phase at 1200°C. The transformation process involves the breaking and recombination of chemical bonds, which belongs to lattice reorganization. It requires a very large amount of energy and is an irreversible process. α-Al₂O₃ and γ-Al₂O₃ have been widely used in industry.

α-Al₂O₃, commonly known as corundum, belongs to the trigonal crystal system with a density of 3.96–4.01 g/cm³. It is an inorganic non-metallic material with extremely stable chemical properties, featuring high hardness (Mohs hardness 9), high melting point (2050°C), high strength, good wear resistance, excellent corrosion resistance, and high resistivity. Therefore, α-Al₂O₃ micro-powder is widely used in fields such as refractory materials, special ceramics, abrasive materials, chemical industry, and electronics.

γ-Al₂O₃ has a defective spinel structure with insufficient aluminum ions and belongs to activated alumina. It is widely used in the alumina family and plays a crucial role in the fields of adsorption, catalysts, and their carriers.

② Corundum

Corundum is the name of a gemstone mineral, which is a naturally occurring α-Al₂O₃ crystal in nature. Pure corundum is colorless and flawless, but it is quite rare. Natural corundum generally contains trace amounts of Fe, Ti, Cr, Ni, etc., thus presenting different colors such as black, dark blue, blue-gray, yellow-gray, brown, tan, and so on.

Corundum can be divided into gem - grade corundum and industrial corundum in terms of usage. Industrial corundum is mainly used in the field of high - grade abrasive materials, and can be made into corundum grinding wheels, grinding discs, abrasive paper and abrasive powder. It is used for polishing and processing metal products, and can be used as bearings for the fast - rotating parts of precision instruments. Ultra - fine corundum powder is widely used for grinding and repairing optical glass of precision instruments.

Due to the shortage of natural corundum supply to meet the demand, artificial corundum has emerged in industry. The main differences between these corundum products lie in the different contents of alumina and their different manufacturing processes.

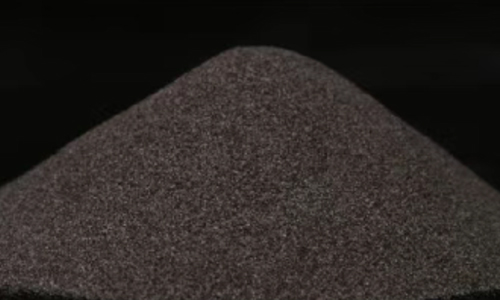

Brown corundum

The main phase in brown corundum is Al₂O₃ (accounting for 94.5% - 97%), and the impurity phases include SiO₂, CaO, Fe₂O₃, MgO, etc. It is brown in color. With high hardness, relatively high toughness and low cost, it is one of the most commonly used abrasives in the field of grinding and is often used for grinding ordinary steel materials.

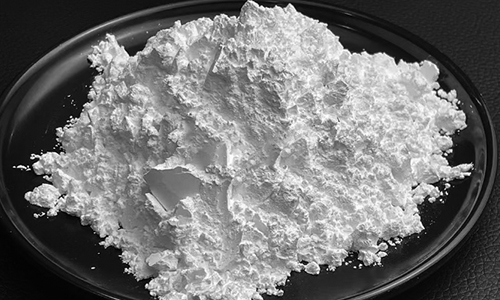

White corundum

White corundum (WA) is made from alumina powder through melting and crystallization. Compared with brown corundum, it has higher requirements for the thermal insulation and air permeability of electric arc furnaces during production. It is pure white in color with high purity, but there are residual pores in its crystals. It is hard and brittle, and its abrasive grains are easy to break during grinding, but it generates little heat. It is suitable for grinding quenched steel, high-carbon steel, etc.

Microcrystalline corundum

The smelting process of microcrystalline corundum (MA) is roughly the same as that of brown corundum, but it requires the molten liquid to be quenched through measures. The resulting abrasive particles are composed of many tiny crystal grains with a particle size of less than 300μm. Due to its better toughness, self-sharpening property and higher strength, it is suitable for grinding carbon steel, stainless steel, etc.

Zirconia corundum

Zirconia corundum (ZA) is made by smelting bauxite or alumina powder and zircon in an electric arc furnace, with ZrO₂ accounting for 25% - 45%. Compared with other types of abrasives, it has excellent toughness and can be used for heavy-load and precision grinding.

Black corundum

Black corundum (BA), also known as artificial emery, is made by mixing and sintering bauxite and coke. It contains iron oxide and a small amount of impurities, and is low in price but has low hardness and poor cutting performance.

③ Sapphire and ruby

Sapphires and rubies are actually high-quality corundums doped with small amounts of different oxides. Rubies are transparent gem-grade corundum crystals in the red series, while sapphires refer to transparent gem-grade corundum crystals in various colors except red. It should be noted that sapphires are not just blue.

In addition to being used as gemstones, sapphire, with its excellent physical, chemical and optical properties, has been widely applied in cutting-edge technologies such as solid-state lasers, infrared windows, substrate wafers for semiconductor chips, and medical treatment.

④ Conclusion

Alumina, namely aluminum trioxide, has the chemical formula Al₂O₃. It has many polymorphic variations, with α-Al₂O₃ and γ-Al₂O₃ being common ones.

Corundum is the name of a gemstone mineral, which is a naturally occurring α-Al₂O₃ crystal in nature. Due to the shortage of natural corundum supply to meet the demand, artificial corundum has emerged in industry, which is divided into single-crystal corundum and polycrystalline corundum.

Sapphires and rubies are α-Al₂O₃ single crystals that exhibit different colors due to doping with small amounts of different oxides, and they are also a type of high-quality single-crystal corundum.