Alumina ceramic is a ceramic material based on aluminum oxide (Al₂O₃), primarily used in thick-film integrated circuits. It exhibits excellent electrical conductivity, mechanical strength, and high-temperature resistance. Notably, ultrasonic cleaning is required for this material. As a versatile ceramic with superior performance, alumina ceramic has found increasingly widespread applications in modern society, catering to both daily use and specialized performance requirements.

Alumina ceramics are divided into two types: high-purity and ordinary.

High-purity alumina ceramic refers to a ceramic material with an Al₂O₃ content of over 99.5%, featuring a high sintering temperature ranging from 1650℃ to 1990℃.

Ordinary alumina ceramics are classified into varieties such as 99% alumina ceramic, 95% alumina ceramic, 90% alumina ceramic, and 85% alumina ceramic based on different Al₂O₃ contents. Among them, 99% alumina ceramic is used for manufacturing high-temperature crucibles, refractory furnace tubes, and special wear-resistant materials (e.g., ceramic bearings, ceramic seals, and water valve plates); 95% alumina ceramic is mainly used as corrosion-resistant and wear-resistant components; due to the frequent addition of part of talc in 85% alumina ceramic, its electrical properties and mechanical strength are improved, enabling it to be sealed with metals such as molybdenum, niobium, and tantalum, and some are used as electrovacuum device parts.

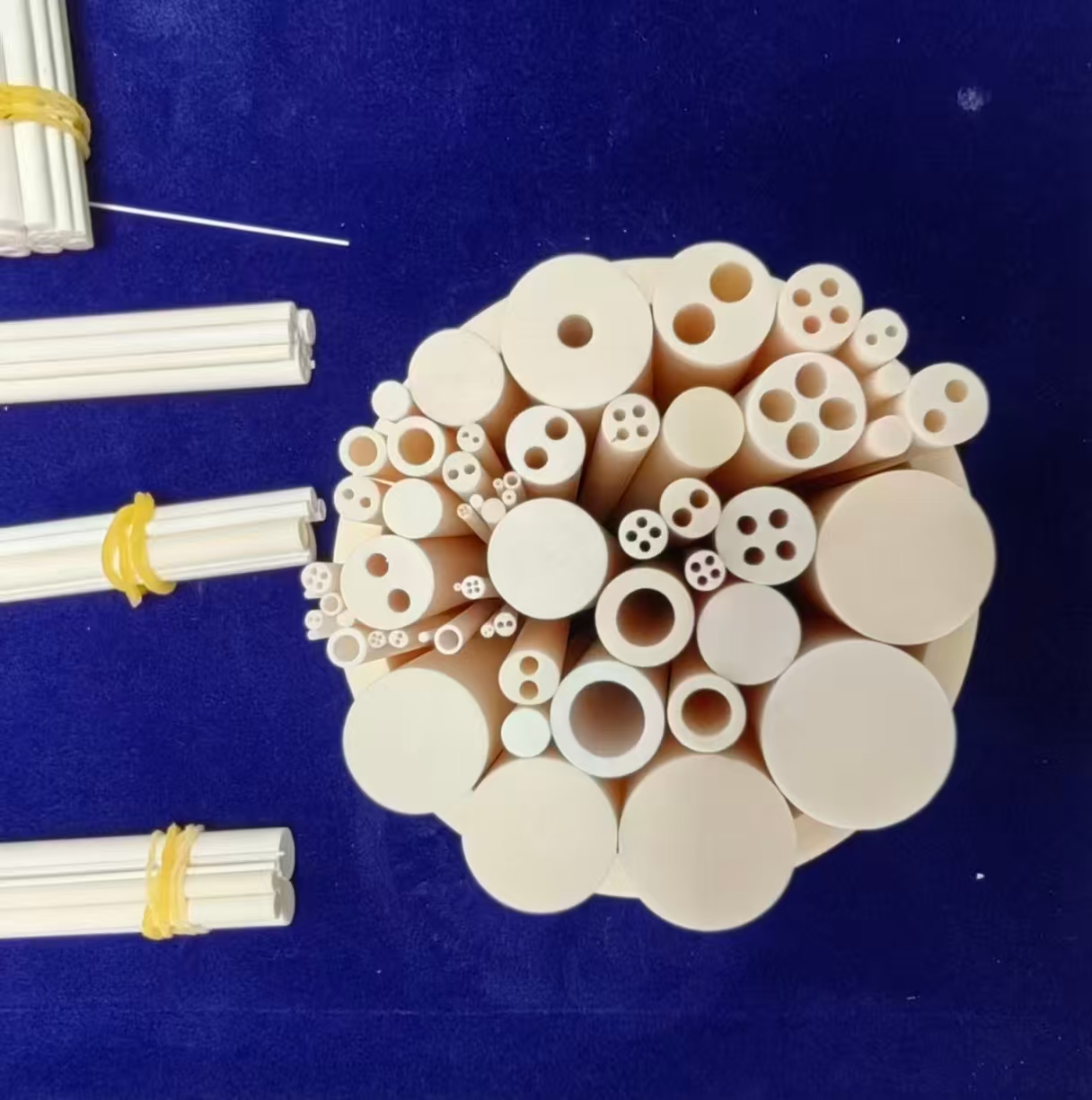

Alumina insulated tube for thermocouple

Application

It is made of materials with good insulation properties, mainly to separate the different poles of the temperature measuring element to avoid interference or short circuits between the two poles, so as to ensure accurate temperature measurement.

Usage

When in use, insert the two poles of the temperature measuring element into different holes in the same direction. After installation, sleeve it with a protective tube for protection.

Material Classification

Depending on the operating temperature of the thermocouple, different alumina contents are adopted, 99.7% alumina ceramic (corundum), 99% alumina ceramic (corundum), 95% alumina ceramic (corundum), and 85% alumina ceramic (high-alumina ceramic). Among the above materials, the higher the alumina content, the higher the operating temperature: the material with the highest alumina content can be used vertically at 1710℃, while the one with the lowest alumina content is suitable for use at 1100℃.

Size

The standard dimensions of alumina thermocouple tubes are an outer diameter ranging from 1mm to 8mm. They are available in single-hole, double-hole, four-hole, and multi-hole configurations, with a minimum inner diameter of 0.5mm and a maximum length of 1800mm. Custom dimensions can also be manufactured to meet user requirements.